With more than 10,186 hectares of production forest, Bao Ha proactively sources raw materials for plywood production facilities.

Facilities for purchasing and classifying wood for plywood production.

Wood is cut to size, order, then fed into the peeling machine.

The peeling line operates continuously, producing thin panels. Workers classify, check the thickness and surface quality immediately after peeling.

The peeled boards are put out on the drying yard to reduce the natural humidity. About 2 - 3 hours, workers will turn the boards to help them dry evenly and meet the standards.

The job of drying planks is suitable for women of all ages. Currently, the peeling plank production facilities in the area are creating jobs for hundreds of local workers, with a stable income of 7-10 million VND per month.

After drying, the boards will be classified again and carefully stacked, bundled before being sold.

The owner checks the quality of the boards before delivering them to the purchasing partner.

Peeled plywood products are produced and consumed, creating jobs and increasing income for local people, helping many households become quite rich and promoting a sustainable local economy .

Mr. Tran Trung Kien - Chairman of Bao Ha Commune People's Committee, said: "Plywood production facilities have made good use of planted forest resources, creating sustainable livelihoods for people. In the coming time, the commune will focus on attracting investment, encouraging deep processing facilities for agricultural products and increasing product value through value chain linkages and technology application. Thereby, the locality hopes to create more jobs for rural workers, promote the economy and sustainably reduce poverty."

Source: https://baolaocai.vn/bao-ha-nang-cao-thu-nhap-cho-nguoi-dan-tu-san-xuat-van-boc-post888534.html

![[Photo] Urgently help people soon have a place to live and stabilize their lives](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F09%2F1765248230297_c-jpg.webp&w=3840&q=75)

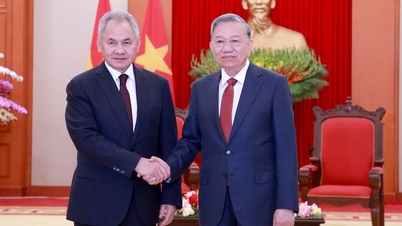

![[Photo] General Secretary To Lam works with the Standing Committees of the 14th Party Congress Subcommittees](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/09/1765265023554_image.jpeg)

Comment (0)