Nambu ironware originated in the mid-17th century, appearing with the rule of the Nambu samurai clan in northern Iwate Prefecture.

With a history spanning over 170 years, the artisans here have carefully preserved and passed down their special skills, ensuring a seamless continuity with the contemporary era.

The origin of Nambu Ironware in Oshu dates back to the late 12th century when the feudal lord Fujiwara no Kiyohira invited artisans from Kyoto to make various items such as Buddhist altar items. Since there were many materials such as quality iron and river sand available since ancient times in the cities of Oshu and Morioka in Iwate, cast iron production has long been popular, and ironware produced in these two cities is called Nambu Ironware.

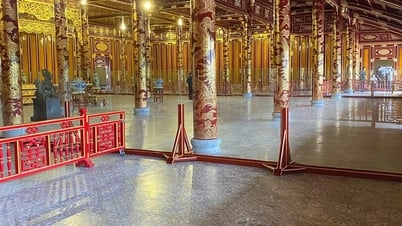

The Oitomi establishment, established in Oshu in 1848, began as a teapot factory under the patronage of Lord Date, and has been around for over 170 years. It is home to many skilled craftsmen whose main focus is creating iron and cast iron utensils using the Nambu crafting technique.

The Nambu Iron Kettle (Nambu tetsubin), a typical example of Nambu ironware, was originally a tea kettle used in tea ceremonies. The Nambu tetsubin is an iron kettle with a dignified and rustic style. The lid and handle are mainly made of iron, while the Arare pattern, characterized by concave-convex dots, has become the symbol of Japanese tetsubin. On the surface of the kettle, a layer of Japanese lacquer is meticulously applied, which not only provides rust-proof properties but also gives the user the pleasure of admiring the deep color of the rust.

Contemporary trends reflect a rise in popularity for trendy shapes and vibrant shades that blend with modern lifestyles.

One of the uses of Nambu ironware is to drink water boiled in iron kettles for health purposes, such as the body absorbing iron ions dissolved in water during boiling to prevent anemia. However, conventional products are large in capacity and heavy compared to the number of people in a household, so there is a need for products with smaller capacity, easier to incorporate into modern life. Japanese cast iron kettles are also called tetsubin.

While iron kettles are used to boil water for tea, cast iron kettles should not be used to boil water. This is because cast iron tea kettles have an enamel coating on the inside, making them unsuitable for use on the stove. Excessive heat will crack the enamel.

Today's kettles were created by improving large tea kettles into smaller ones, adding a spout and a handle so that hot water could be poured with one hand. The traditional design of iron kettles, even today, has much in common with tea kettles made 400 years ago.

In the foundry, there are many essential materials for making cast iron, such as hard coke and iron. Oitomi uses the sand casting method. Nambu ironware production involves many processes such as taking fine sand in a box and then feeding it into a mold press by hand; using a wooden model to create a mold while mixing sand and clay; attaching designs such as arare (hail) or sakura (cherry blossom) to the mold; drying the mold and firing it at high temperature; pouring molten iron into the mold; removing the iron from the mold, removing the core, and continuing to fire it at furnace temperature.

Foundry workers carefully inspect even the smallest ironwork for flaws. Defective pieces are melted down and cast into new ones. Finished pieces are polished, lacquered, and painted. This attention to detail makes the products here highly regarded and sought after.

Kaiko Kikuchi, the ninth generation owner of Oitomi, introduced hundreds of molds from the workshop. According to him, Oitomi has at least 100 years of designs in its archives, so the workshop can reproduce products from those periods.

The company’s Miyabi iron kettle, which features a soft shape and blue coating, became an instant hit when Los Angeles Dodgers player Shohei Ohtani, who is from Oshu, featured the product on his Instagram account. Since then, there have been around 3,000 orders and a year-long waitlist.

Craftsman Kaito Kikuchi has been looking for ways to ensure that traditional crafts can survive. He stresses the importance of expanding markets by developing new sales routes overseas. In order for younger generations to join traditional industries and learn skills to pass on, he believes it is necessary to change the business model to one that can guarantee income.

Craftsman Kaiko Kikuchi, the ninth generation owner of Oitomi, said that Nambu Ironware has gone through many difficult times, and the war was one of them. During the war, the production of iron kettles was banned because the iron had to be used for the government to produce weapons. However, the artisans at that time feared that if they melted down all the Nambu Ironware to make weapons, not only the things they made, but also the culture of Japan as a whole and the culture of the local area, would disappear, so the artisans persuaded the government.

“Not only wars, but also other difficult times like earthquakes, tsunamis, hurricanes or volcanic eruptions. In the midst of all of this, the reason we have stood up so many times is because we fundamentally love what we do. I think that is the most important thing,” he said.

Today, one-third of Oitomi's online sales are overseas. Taking advantage of the growth of overseas markets to turn a traditional craft into one that young people can easily participate in is the secret to Oitomi's successful preservation and development of Nambu Ironware./.

Source: https://www.vietnamplus.vn/oitomi-su-tiep-noi-lien-mach-tu-truyen-thong-den-thoi-ky-duong-dai-post982865.vnp

Comment (0)