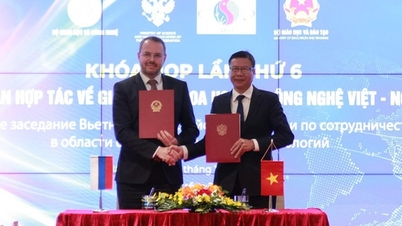

Project view

Project view

The maintenance and repair project of the Hydrogen Manufacturing Unit (HMU), invested by Nghi Son Refinery and Petrochemical Company Limited (NSRP), was implemented in 25 days, of which 10 days were spent on stopping and restarting the system. Previously, the plant had undergone a general maintenance period in 2023. This maintenance period plays an important role in ensuring the integrity of the equipment and maintaining the stable operation of the HMU until the next general maintenance period, scheduled to take place in 2027.

According to the signed contract, PTSC Quang Ngai is responsible for key items including replacing the entire manifold system of 04 Reformers equipment clusters; removing and cleaning to check the condition, replacing the center pipe and refractory material at 04 Waste Heat Exchangers. Different from previous general maintenance periods (Turnaround - TA), this maintenance period is called Pit stop, meaning that the workshop is only isolated to carry out work under the condition that the factory is still operating with the nature of the work not only as normal BDSC but also for technical handling and repair of the Defect Confirmation Shutdown Maintenance (DCSM). Working conditions pose many challenges for the implementation team as most of the work is done in a confined space, the scope of operations is limited within the permitted and designated range, all communication must be done using explosion-proof walkie-talkies to completely replace the telephone as in TA, which greatly limits communication, information exchange and timely work handling.

In addition, the project includes a large volume of mechanical and welding work - Hot Works - with high technical requirements, specialized materials for Reformer/Furnance such as Aged Alloy 20Cr-32Ni, Incoloy 800H, Stainless Steel TP347H and Chrome-Molybdenum Alloy A335/P11 are all in the group of difficult-to-weld materials, with large thickness, requiring welding work to strictly and absolutely comply with the welding process, especially the temperature between welding layers and intermediate inspection steps must comply with ITP. In fact, there are many stages and intermediate inspection steps of the mandatory stop type - Hold Point - before moving on, making it almost impossible to increase manpower to speed up progress by conventional methods.

Representatives of PTSC Quang Ngai Board of Directors and construction units visited and inspected the project progress.

Representatives of PTSC Quang Ngai Board of Directors and construction units visited and inspected the project progress.

Despite the large workload, complex construction conditions and high safety requirements, the project progress has been maintained steadily up to now. Many important items have been completed according to technical requirements thanks to the proactive organization, flexible response ability of the construction team and the high sense of responsibility of each officer and employee of PTSC Quang Ngai.

This Pit Stop for HMU workshop affirms the experience and capacity of PTSC Quang Ngai in implementing mechanical items, especially technical processing and welding for some typical materials for Reformer/Furnance/Boiler... with strict requirements and high demands on quality. Mastering Mechanical and Hot Works repair work is an important foundation for the enterprise to continue to consolidate its position in key industrial maintenance and repair projects nationwide.

Truong Thi Diep Ha

Source: https://www.ptsc.com.vn/tin-tuc/tin-ptsc-1/san-xuat-kinh-doanh/ptsc-quang-ngai-day-nhanh-tien-do-bao-dung-sua-chua-phan-xuong-san-xuat-khi-hydro--nha-may-loc-hoa-dau-nghi-son

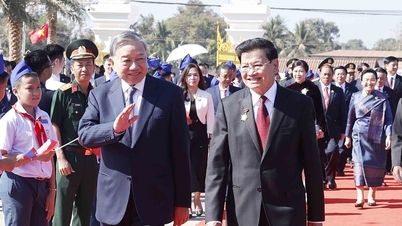

![[Photo] Parade to celebrate the 50th anniversary of Laos' National Day](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F02%2F1764691918289_ndo_br_0-jpg.webp&w=3840&q=75)

![[Photo] Worshiping the Tuyet Son statue - a nearly 400-year-old treasure at Keo Pagoda](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F02%2F1764679323086_ndo_br_tempimageomw0hi-4884-jpg.webp&w=3840&q=75)

Comment (0)