|

Durability and long-term usability have long been key features that Apple emphasizes when discussing its products. Not only does this give users more reasons to buy new phones, but the increased durability of iPhones also means that older devices will be resold or given away, further increasing the number of Apple iOS devices, which has now reached 2.5 billion. |

|

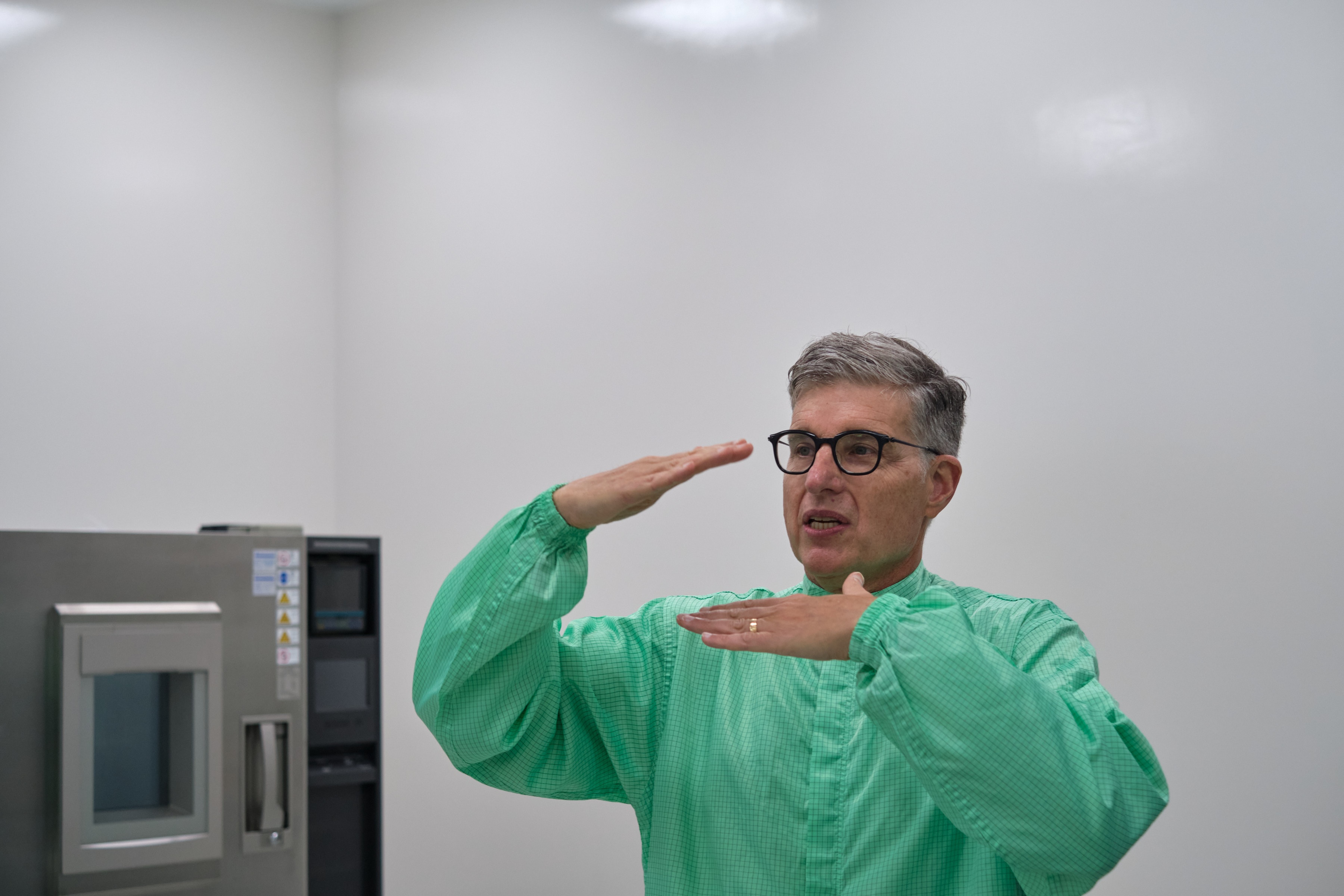

On January 30th, Apple held its first-ever visit to its component durability testing lab in Asia. A small group of reporters and experts were invited to Apple's factory in Ang Mo Kio, Singapore's high-tech industrial park. This is where Apple houses key manufacturing facilities, research labs, and testing centers, including the camera component durability testing lab. Each component of the iPhone and other devices undergoes individual testing for years before the final product is released. Tom Marieb, Vice President of Product Integrity, Apple's hardware division, shared insights into this process. |

|

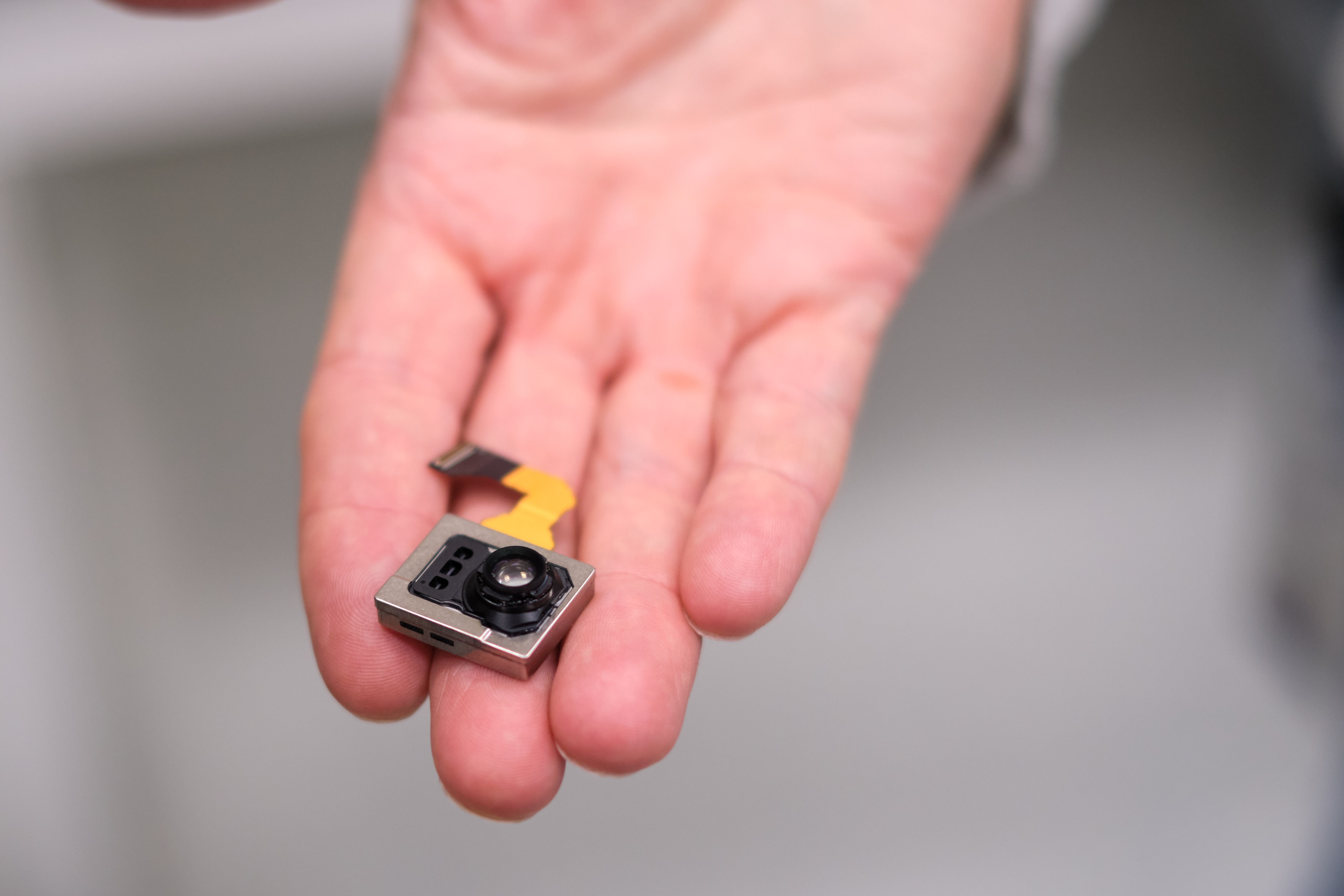

Apple has numerous factories around the world to test each component, with each group going through multiple stages. Only when the design is finalized are the components mass-produced and assembled into the complete product. Thorough testing through multiple steps is Apple's way of ensuring each component meets the design standards even before the final product is formed, because they cannot correct errors afterward. The image shows the camera assembly of the iPhone 15 Pro Max. |

|

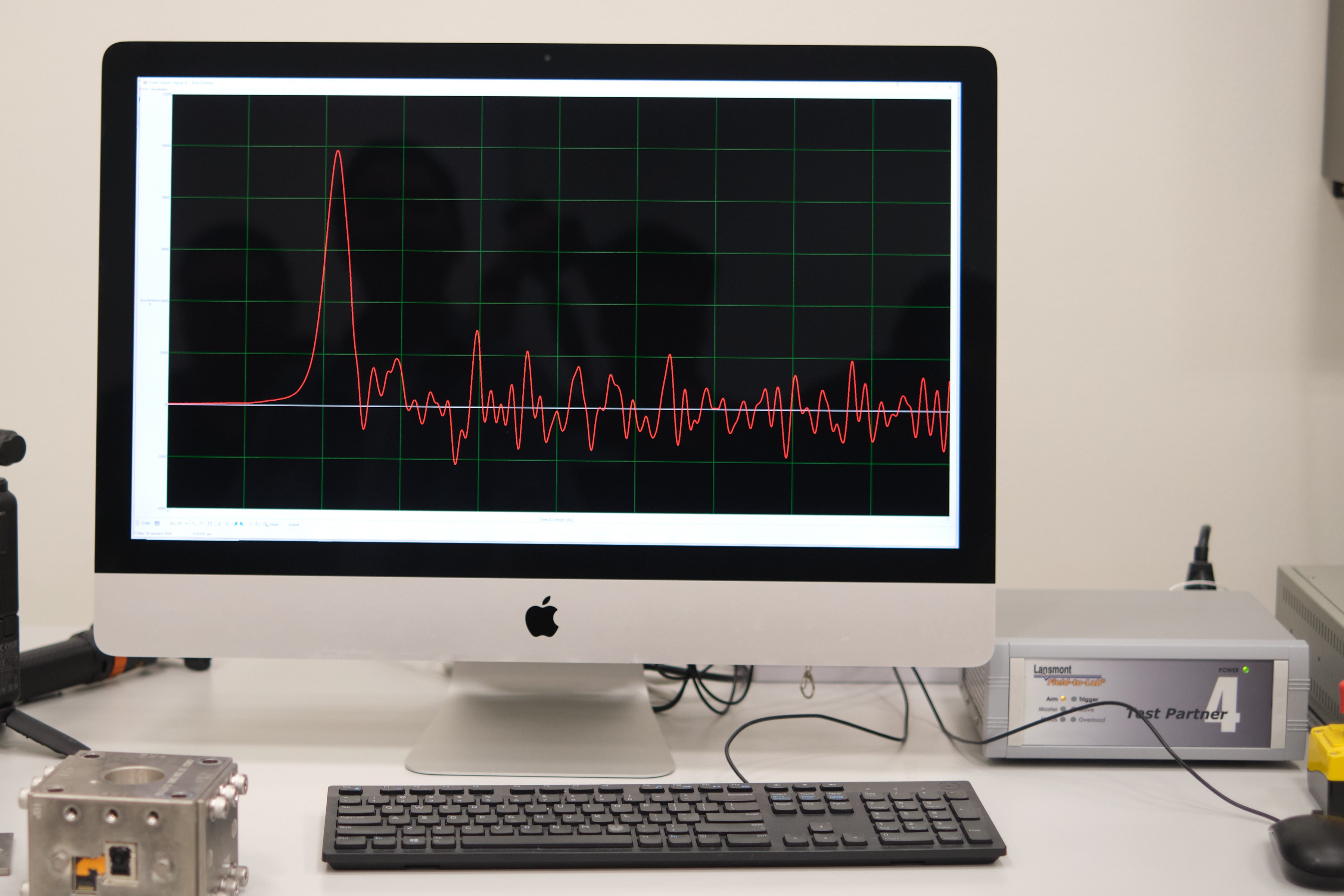

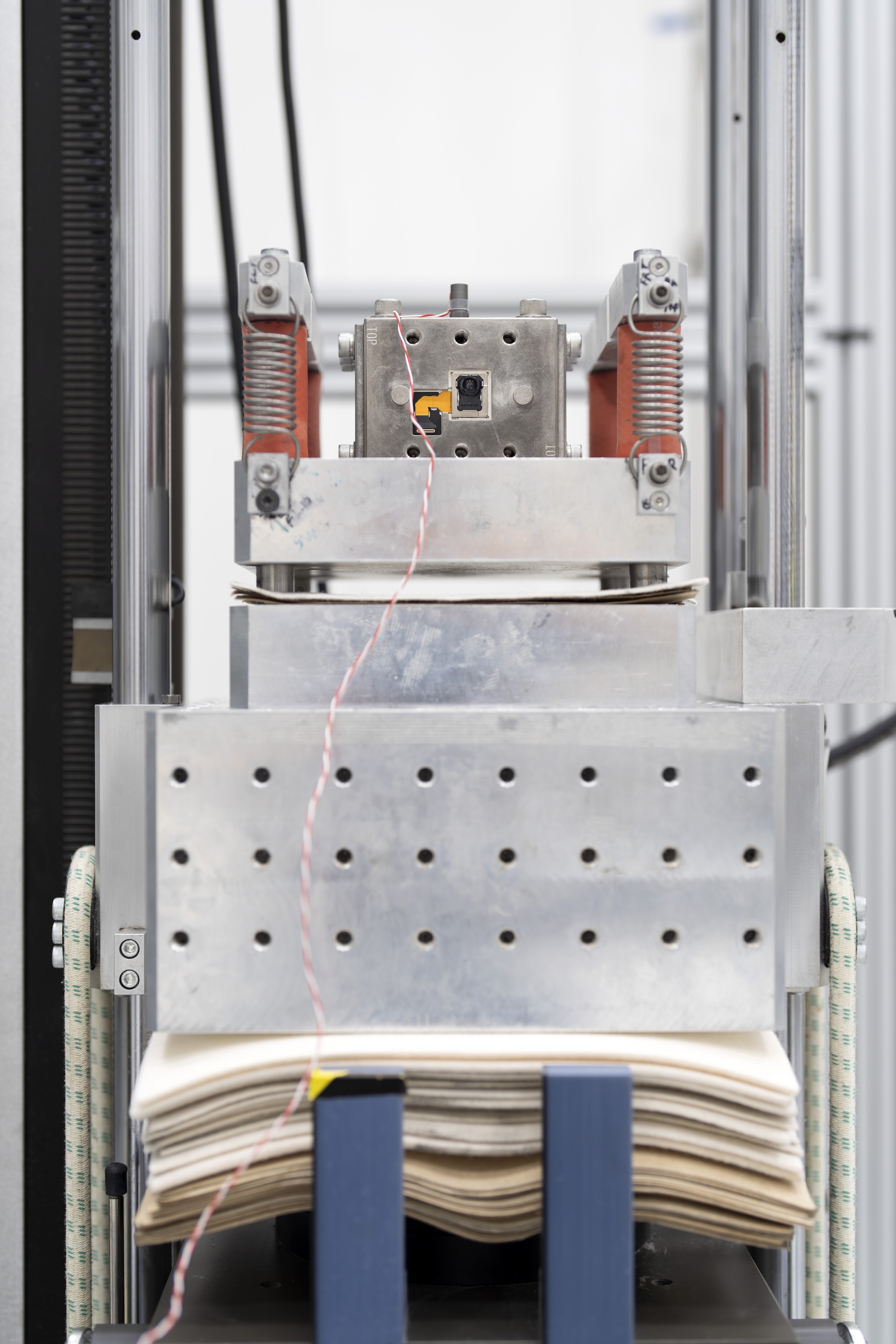

The durability of a device is assessed using various criteria. For the camera module, common tests include drop resistance, humidity, and temperature. The image shows a set of weights weighing approximately 5 kg for the impact resistance test. |

|

The camera array is attached to a weight and dropped to create a pressure of up to 10,000 G for a moment, which is displayed on a force graph as shown on the screen. |

|

The test was conducted from various angles. To check if the camera was damaged after the test, Apple used microscopic lenses that can capture clear images of each pixel on the sensor. |

|

To verify the environmental impact, components are subjected to testing machines with much harsher conditions than reality in order to shorten the testing time. Pictured is a machine simulating an environment with 85% humidity, to test the effect of humidity on surface leakage. |

|

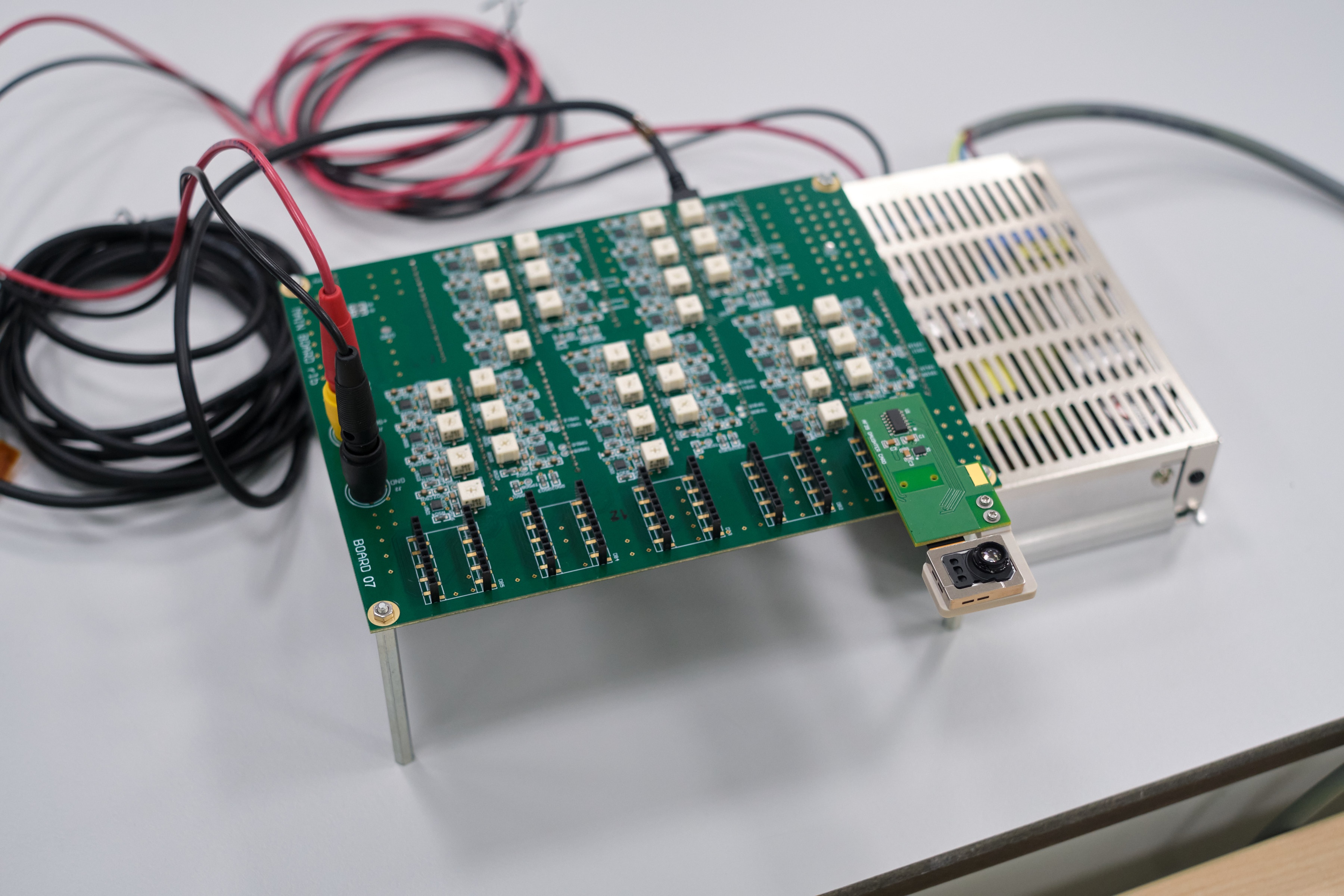

The circuit board in the image is used to test the effect of voltage on the component assembly. The camera assembly is connected to a higher voltage than the normal operating environment. Temperature, humidity, and voltage are the factors that can most significantly affect metal corrosion. |

|

Inside this machine, components are placed in an environment where the temperature changes from -40°C to 85°C every 30 minutes. Through this "temperature loop," the machine tests the expansion of different materials within the same component assembly. |

|

Another machine also tested the effects of temperature, but to find the impact on adhesives. Components were immersed in water at 85 degrees Celsius, lifted out, and then immediately submerged in a liquid at -40 degrees Celsius. The entire cycle lasted only one minute—a rigorous test to find the type of adhesive that was least affected by temperature changes. |

|

The machine is likened to a "pressure cooker" at the Apple factory. When the doors are closed, the pressure and humidity inside are pushed to levels much higher than in a normal environment. This test helps to assess the impact of conditions such as rain. Apple states that 96 hours of testing inside this machine is equivalent to 10 years of use outside, shortening the testing time. |

|

The level of simulation was carefully considered to both speed up the testing time and avoid making the "difficulty" too high, to the point where users would never encounter it in real life. |

|

Throughout the hardware design process, this is also a balance that Apple must consider to ensure the product is both durable enough and meets the requirements for thinness and weight. |

|

An Apple representative stated that each product could be even more durable if the company sought to "design beyond" durability, but this would make it difficult to achieve impressive design elements. Therefore, product design needs to find the right balance. |

Source: https://znews.vn/ben-trong-nha-may-apple-thu-do-ben-iphone-post1624234.html

![[Photo] President Luong Cuong receives Speaker of the Jordanian House of Representatives Mazen Turki El Qadi](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2026%2F02%2F03%2F1770112220330_ndo_br_1-3704-jpg.webp&w=3840&q=75)

![[Photo] Prime Minister Pham Minh Chinh receives Philipp Rösler, Chairman of the Switzerland-Vietnam Economic Forum.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F402x226%2Fvietnam%2Fresource%2FIMAGE%2F2026%2F02%2F03%2F1770121222295_ndo_br_dsc-8709-jpg.webp&w=3840&q=75)

Comment (0)