“Rice has helped Vietnam escape from poverty. And personally, I think "Make in Vietnam" chips will help Vietnam become a developed country in the future," said Mr. Nguyen Thanh Yen, Member of the Board of Directors of the Vietnam Microchip Community.

Necessary and sufficient conditions to have a "Make in Vietnam" chip

With nearly 20 years of experience in the field of IC design, Mr. Nguyen Thanh Yen, Member of the Board of Directors of the Vietnam Microchip Community, understands quite well the "bright spots" as well as the "gray tones" of the Vietnamese chip industry. Male.

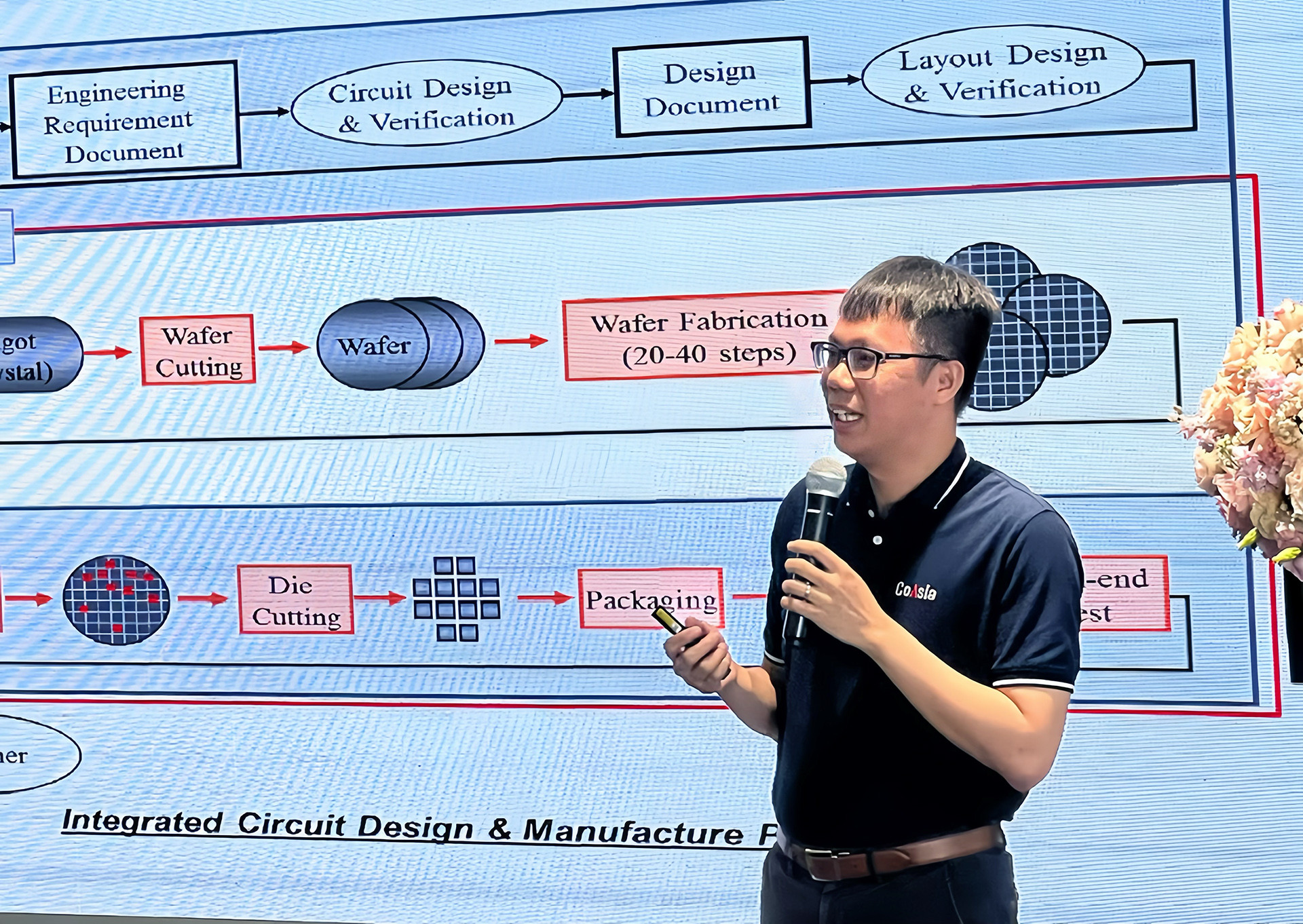

Mr. Nguyen Thanh Yen, Member of the Board of Directors of Vietnam Microchip Community (Photo: Binh Minh)

“I have spent nearly 20 years in the profession, starting with a startup, then going abroad to work for a company that is on the list of the largest semiconductor companies in the world. After that, I returned to Vietnam with the desire to become the first domestic company that can earn its own money, and is currently building a team of Vietnamese engineers to participate in world-class projects using advanced technology. The most advanced technology process – 5nm. In every place, I have interesting memories, but the most interesting memory I want to share with you is the first chip in my life," Mr. Yen opened the story with VietNamNet reporters.

In 2004, while a final-year student at Hanoi University of Science and Technology, Nguyen Thanh Yen was accepted into a new startup company, specializing in power management chip products, founded by an American businessman from his childhood. Ngu lives in Vietnam.

After a period of training, Nguyen Thanh Yen and another friend were assigned the task of designing an LDO chip with 3 pins with a very simple voltage stabilization function, the circuit contained only on an A4-sized page.

“When I received the news that my chip was put into production (tape-out), I was very happy. I ran all the way to the rooftop and screamed loudly. It was on a winter night, near Tet," Mr. Yen said.

However, 3 months later, holding the tiny chip in hand, soldering it to the circuit board, turning on the power and starting to check and measure, the chip... did not work. Struggling for half a day, not knowing what to do, Nguyen Thanh Yen ran into the Director's room to ask for help.

“The director is the one who taught me a lot about chip design. I think he will help me again like always. But his answer has become the most "interesting memory" for me, has followed me throughout my journey of nearly 20 years and will continue to follow me for many more years to come. He said: "The chip was designed by me, not mine, I should be the one responsible." I don't need to say more, you all understand how I felt at that time," Mr. Yen smiled.

After 6 more months, I still couldn't find the problem. The feeling was getting worse and worse. I was confused like I had hit my head on a big rock and didn't know what to do next. When it seemed like he had to throw up his hands and surrender, during a trip to work on FIB (wiring technique after the chip was manufactured), accidentally due to a mistake during work, Nguyen Thanh Yen found the cause. The reason why the chip does not run is that the information given by the factory (FAB) is incomplete when the BJT component operates at very low current conditions - less than 10nA, so when running the simulation, it cannot generate output. problem appears.

“Until now, I still secretly thank the Director for what he said that day. As a design engineer, you don't simply stop at drawing circuits, simulating, and checking that they run correctly according to the parameters in the technical specification document, but you must take full responsibility for your design. . Of course, that chip of mine never appeared on the market because 6 months was enough for the competitor to surpass us, releasing a chip with similar features to the market first. Luckily for me, even though I caused damage to the company, I was not fired and the second chip I participated in designing had quite good sales," Mr. Yen happily recalled old memories.

Returning to reality, Mr. Yen noted: Companies operating in the field of chip design in Vietnam currently have quite a few Vietnamese engineers participating in the design stage, which is a mandatory step to understand. and master it. We have a skilled team available. This team will grow larger as large companies and corporations continue to invest in Vietnam.

“Vietnam has a chip design team of about 5.000 skilled engineers at all stages of the design process. Along with that is a large force of pupils, students, and researchers, with qualities inclined towards technical professions. That is a necessary condition. However, Vietnam still has limitations on ownership of designs. If we understand "Make in Vietnam" in the sense that we are the owners of the designs, the chips and have the autonomy to commercialize (sales), then we are seeing that it is a limitation in sufficient conditions", Mr. Yen Answer the question "What are the necessary and sufficient conditions to have a "Make in Vietnam" chip?

There are still "gaps" that need to be filled

According to Mr. Yen, the chip manufacturing field in Vietnam has almost no significant foundation. Recently, we heard the news that Samsung has begun to expand into high-end chip packaging in Vietnam, or plans to establish a computer chip packaging and testing factory for Intel Vietnam, ON semi, and Hana. Micron, Amkor... These companies are all companies with direct investment capital abroad. In factories, they use highly automated processes, with machines playing a major role.

Vietnamese companies have not yet been able to participate in the semiconductor manufacturing ecosystem.

"I think, currently, Vietnam is not really ready for "Make in Vietnam" chip manufacturing activities. If so, we are only a source of human resources in packaging and testing activities or supporting fields. in chip production. Every year, we have more than half a million students registering for university admission. If only a small portion of these register to study IC, in the next few years we will have a large workforce, ensuring human resources for any investment plan to develop the semiconductor industry in Vietnam. If there will be any male in the future", Mr. Yen commented.

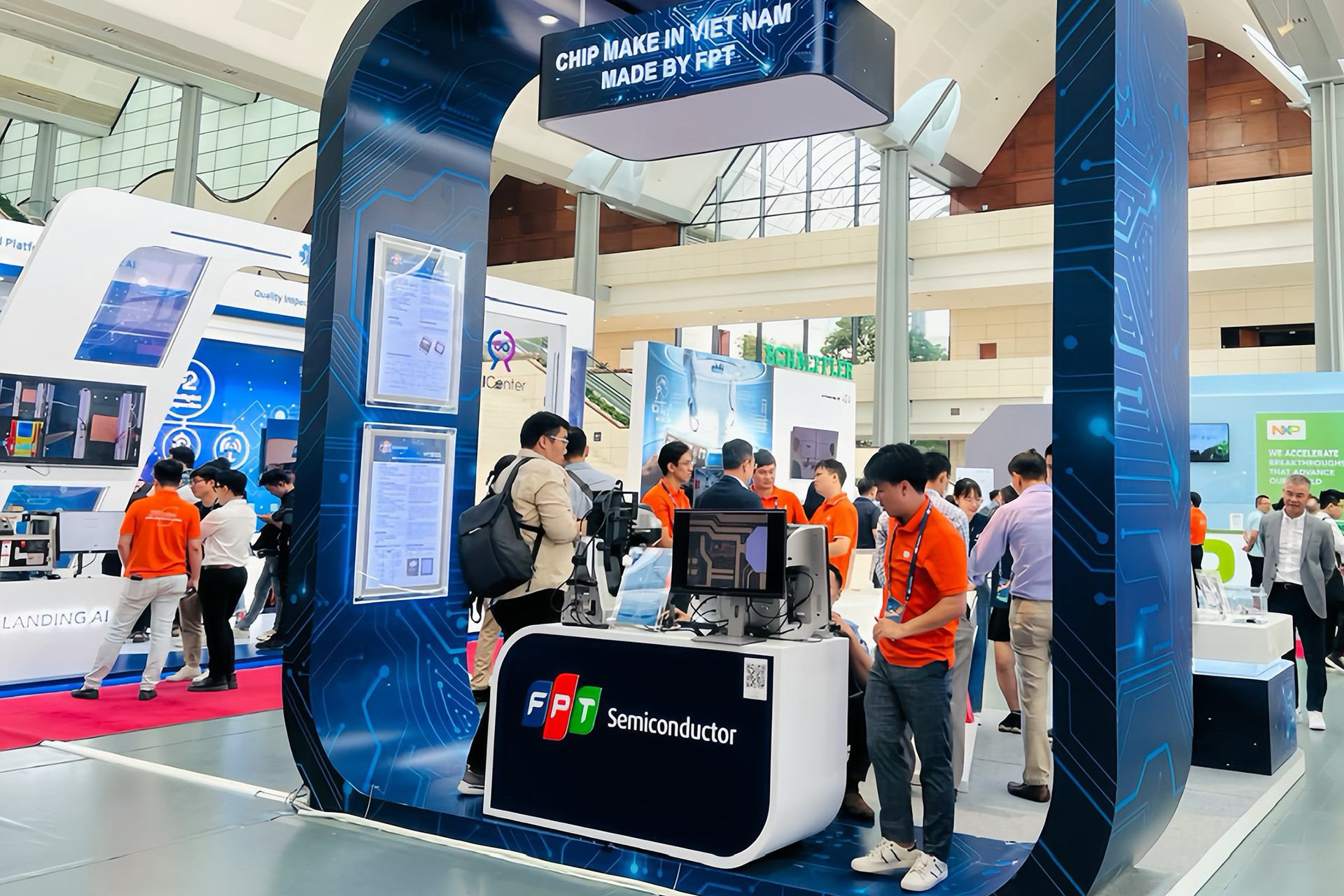

Recently, FPT and a number of Vietnamese enterprises announced that they have produced "Make in Vietnam" chips (Photo: Binh Minh)

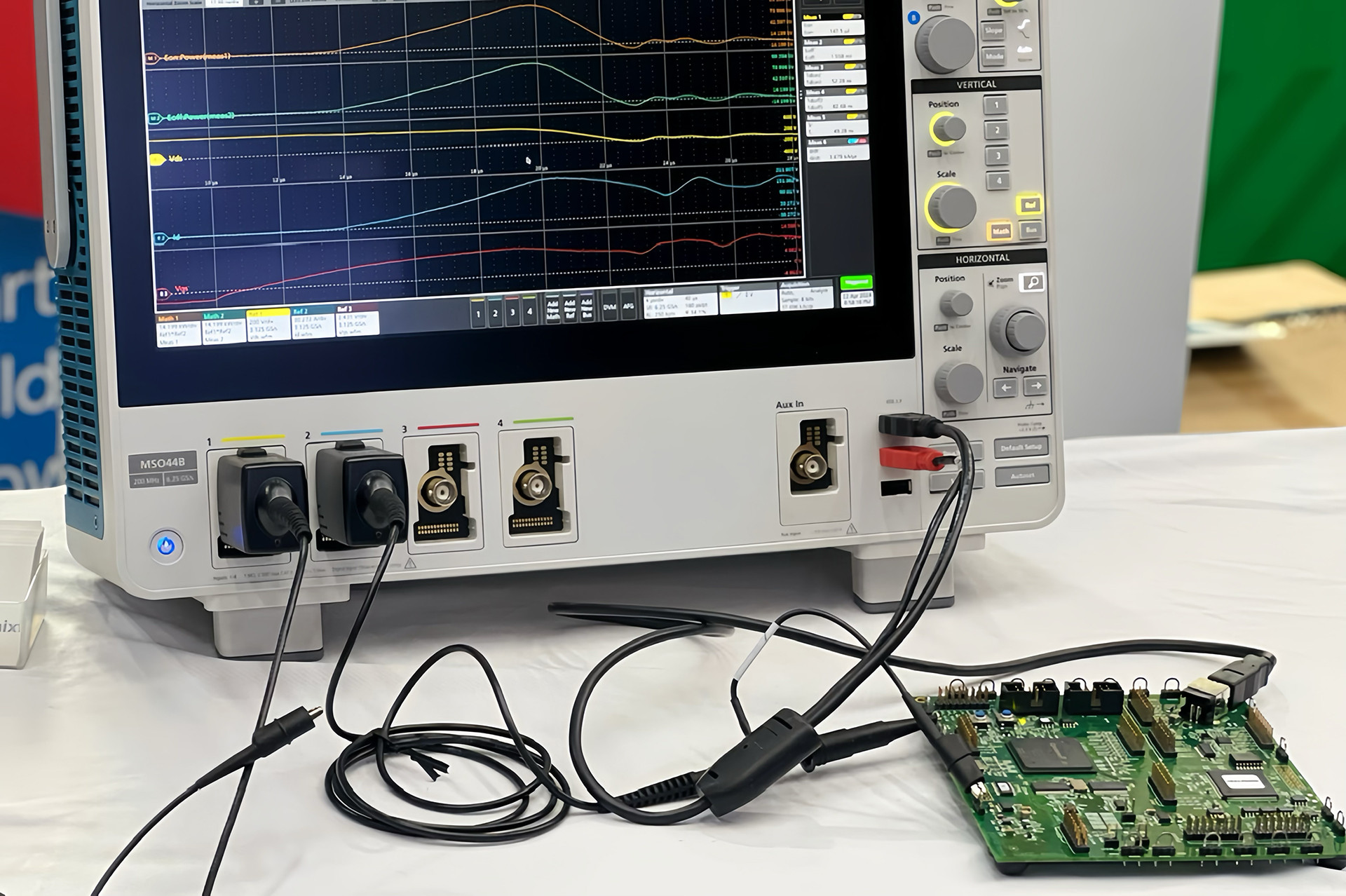

Recently, a number of Vietnamese businesses announced that they have produced "Make in Vietnam" chips. Sharing his personal feelings about this story, Mr. Yen said: Talking about microchips is talking about mass production, in extremely large quantities. For example, a wafer with a diameter of about 200mm can produce about 20.000 chips with a size of 1mm^2. A medium-sized semiconductor factory with the capacity to produce 50.000 wafers/month, this factory alone can can produce more than one billion chips/month.

“A design when put into production, assuming only 1/10 of the production capacity of a mid-sized factory, will produce hundreds of millions of chips per production batch. Personally, I think there is still a long way to go and there are still many obstacles for Vietnamese businesses before reaching the milestone of selling 1 billion chips," he said.

The semiconductor industry has a very wide scope, including: Design; manufacture; pack; machinery and raw materials for production; Computer tools support production design…

Chips have increasingly high integration density. To produce a chip requires the participation of many parties. Chips then serve as input materials for the electronics manufacturing industry.

"If "Make in Vietnam" chips are understood as Vietnam owning or contributing to the majority of the value chain, then Vietnamese chips need to be ready to compete fairly on a global scale in terms of quality, price and availability. Meet and deliver orders on time. The "gap" we need to fill is the gap of people starting late, or in other words we need to find a way to go faster," the chip design expert shared.

For several months now, the story of Vietnam becoming the "chosen one" in the new generation global chip supply chain has positively inspired the domestic semiconductor chip community.

"Chosen One" is a way of saying that conveys the message that Vietnam is facing a unique opportunity to participate more deeply and play a larger role in the global chip supply chain.

The Covid-19 pandemic startled the whole world to realize the importance of diversity in the semiconductor chip supply chain. The world's famous car companies will not allow the failure to produce a new car model on time just because of the lack of a semiconductor component from China.

Vietnam has a very special geographical location. If we take Vietnam as the center with a compass radius of 4 hours of flight time, we will almost cover a very large area of Asia. This is an area that accounts for a large proportion of the global semiconductor market, and is said to be the place that shapes the future development of the semiconductor field. The location allows for optimal logistics costs and increasingly perfect infrastructure, bringing a huge geographical advantage to Vietnam.

In the field of semiconductors, the United States is the cradle of development of technology companies and startup ecosystems. The United States will always campaign to affirm the number 1 position in technology globally, they have the ability to lead the market, allocate, and reposition the value chain. Vietnam and the United States upgrading their relationship to a comprehensive strategic partnership is an opportunity to develop Vietnam's semiconductor industry.

In addition, over the past 20 years, Vietnamese engineers have gradually demonstrated their ability at work, thereby gaining the trust of management levels abroad.

Currently, Vietnamese engineers are assigned jobs that require high expertise and many challenges in chip design projects. More and more important projects involve engineers working in Vietnam offices, and more and more large companies decide to set up offices or expand the scale of chip design engineers in Vietnam. Male.

Especially in recent years, the number of engineers from Vietnam going abroad to work for companies in the Top 15 largest semiconductor chip companies globally has increased significantly. More than 10 years ago, this was rare because the resumes of engineers who only worked in Vietnam were often not highly appreciated.

“As I mentioned earlier, the design stage plays an important role. It is the force of Vietnamese design engineers that is the "anchor" that keeps large semiconductor companies and corporations continuing to invest in Vietnam. Those are very important premises. Taking advantage of the opportunity with the right investment, I believe we will soon have a "Make in Vietnam" chip capable of competing fairly in the world market," Mr. Yen emphasized.

The story of Vietnam becoming the "chosen one" in the new generation global chip supply chain has positively inspired the domestic semiconductor chip community (Photo: Binh Minh)

Vietnam's great aspiration

In Vietnam, just 4 years after unification, in September 9, Z1979 Semiconductor Factory was established, starting to carry out contracts to produce and export diodes and transistors.

By the late 80s and early 90s of the last century, due to world political fluctuations, the factory no longer had semiconductor production orders, and the production and packaging of microchips at the Z181 factory had to stop. again.

In extremely difficult conditions regarding materials and not enough priority electricity for research, Vietnamese engineers still achieved certain achievements that are very proud of in nearly 10 years of operation, contributing marking and laying the foundation for the field of Vietnamese IC design and manufacturing.

By the late 90s of the last century, overseas Vietnamese engineers returned home, starting a period of growth in the number of chip design engineers working in circuit design centers in the city. Ho Chi Minh, Da Nang and Hanoi.

Vietnamese engineers are contributing to the design of microchips used in cars, telecommunications network equipment, and billions of other consumer electronic devices widely used around the world.

It can be said that Vietnam participated in the field of semiconductor ICs very early. Exporting "Make in Vietnam" chips is not purely a "dream" but a "secret" aspiration of many generations. Making chips requires a lot of perseverance. Vietnam has persevered for more than 40 years and will continue to persevere. Chips are acting as a new resource to ensure the development of the electronics industry and the digital economy. Becoming a part of the semiconductor supply chain is a mandatory choice for any country or organization that wants to go on the path of sustainable development through digital economic development.

Mr. Nguyen Thanh Yen proposed a series of proposals for Vietnam to truly become an important link in the global semiconductor industry value chain (Photo: Binh Minh).

“We have been exporting “Make in Vietnam” chips since the 80s of the last century, and recently, according to information in the mass media, Vietnam has a company that started exporting “Make in Vietnam” chips. in Vietnam". The role of chips in the digital economy can be compared to that of rice grains in ensuring human sustenance. History shows that rice grains have helped Vietnam escape from poverty. And personally, I think the "Make in Vietnam" chip will help Vietnam become a developed country in the future," Mr. Yen expressed.

With the perspective of an expert with many years of experience and enthusiasm in the field of IC design, Mr. Nguyen Thanh Yen offers a series of proposals for Vietnam to truly become an important link in the industry value chain. global semiconductor.

From the perspective of state management, research should first focus on two groups of policies including: Group of policies to encourage human resource development; Group of policies to encourage the development of domestic enterprises, or encourage domestic enterprises to enter into joint ventures with foreign enterprises.

Accordingly, focus on developing human resources in the next 5 - 10 years to reach a large enough number of human resources, for example 10.000 - 20.000 engineers. IC training needs to be combined between schools and businesses. The school builds integrated and continuous circuit design and manufacturing subjects; Choose to invest in an educational institution that has the advantage of linking with international schools/institutes or businesses that can support students to experience real-life project work and prototyping activities. , and guaranteed job placement after graduation.

On the other hand, it is necessary to issue preferential policies to reduce personal income tax to promote the attraction of engineers and IC experts to stay and work in Vietnam. While the average income of engineers in Vietnam is still modest compared to other countries, our personal income tax is quite high, which does not attract experienced engineers to stay in Vietnam to work. , nor does it attract students to study the semiconductor field. Vietnam is creating a policy disadvantage in the race to attract experienced IC engineers to work in Vietnam. Keeping and maintaining a large team of experienced engineers in Vietnam will be the key to developing the semiconductor chip field in the near future.

In addition, Vietnam also needs to strengthen state diplomatic activities to simplify visa and residence card procedures for Vietnamese citizens working in the field of microchips when going to work in the US and Europe. , Korea, Japan, Taiwan (China), Malaysia..., as well as citizens of the above countries and territories coming to work in Vietnam.

Issue specific instructions consistent with the actual operations of businesses, so that foreign businesses investing in the field of microchips or businesses in Vietnam are directly operating in the field of microchips regardless of their status. Big or small, they can easily receive incentives from the Government's tax and infrastructure policies.

Adding regulations to simplify the import and export of electronic components, computers, and servers for entities operating in the field of chip design. Because bringing microchips to the market requires an ecosystem of electronic equipment manufacturers to create sample products, but currently, regulations on import and export of high-tech electronic devices are changing. It is not very convenient for units that design, manufacture, produce, and test small quantity sample products in Vietnam.

In addition, it is necessary to specify policies to support and promote increasing the localization rate of electronic products. This contributes to creating domestic consumer demand for microchip products designed and manufactured in Vietnam. This policy will also promote cooperation between business groups in Vietnam, contributing to the formation and development of an ecosystem for developing domestic microchip products.

Establishing and sponsoring the Vietnam Semiconductor Circuit Technology Association is also something that needs attention and implementation to create a consistent, official, and convenient information hub for domestic and foreign organizations and individuals who wish to Learn about and contribute to the development of the IC field in Vietnam, and advise and support the implementation of the semiconductor industry development strategy.

“Nearly 20 years ago, during a business trip in Shanghai - China, I and some of my friends promised each other that we would bring microchips to Vietnam. Until now, I am still trying to realize that promise by doing my best to contribute my small part to bring the most job opportunities to Vietnamese young people," said Mr. Feel free to talk more before stopping the story.

| The Vietnam Microchip Community was founded by a group of engineers working for chip design companies in Vietnam, with the goal of gathering people working in the same field to exchange and share questions. career story.

After 4 years, the Vietnam Microchip Community is receiving more and more attention from society and has more than 24.000 members who share the hope that the microchip field will increasingly develop in Vietnam. Recently, the Vietnam Microchip Community has compiled and provided a lot of valuable, reliable, and practical information about the current status of the field of IC design in Vietnam as well as in the world; Connecting professionals as well as those interested in the field of IC design. The Vietnamese Microchip Community is ambitious to promote semiconductor chip startup ideas in Vietnam in the near future. |

Vietnamnet.vn

Source: https://vietnamnet.vn/chip-make-in-vietnam-se-giup-viet-nam-tro-thanh-nuoc-phat-trien-2274921.html