In Dong Thap, a group of young people have successfully produced paper from lotus stems, which can be used in art, gift bags, and decorative labels, helping to protect the environment.

Nguyen Thi Thuy Phuong, 42, the research team leader, shared that she spent eight years working in Northwest Vietnam and experienced firsthand how the Mong and Dao ethnic groups make paper from plant materials.

Upon arriving in Dong Thap, she noticed a large amount of by-products from lotus stems that farmers were either cutting down or burying in the ground, which gave her the idea to make paper from them. Midway through this year, the team began researching, conducting numerous experiments, and finally discovered a process for producing paper from lotus stems.

Lotus stems – an agricultural byproduct that is abundant but underutilized, often cut down or buried in the ground. Photo: Ngoc Tai

According to traditional paper-making methods, lotus stems are boiled in lime water for 6-8 hours. The workers then separate the fibers (cellulose) from the stems, clean them, and soak them in microorganisms for about a week, which helps the fibers whiten naturally and removes any remaining residue.

The fibers are pounded finely in a stone mortar and mixed with water to create a pulp. This mixture is then placed on a frame and evenly distributed using a hydraulic nozzle. Compared to manual distribution, the nozzle produces a flatter and more uniform paper. The paper is then dried for about two hours before use.

According to the research team, lotus stems contain about 30% cellulose, only slightly less than lotus pods, but the plant fibers from the stems can self-link. Lotus paper has the advantages of being flexible, tear-resistant when crumpled, highly absorbent, and having a natural scent. Bags and packaging made from lotus stems can use plant-based adhesives to increase their strength.

On average, 10 kg of lotus stems yield 0.6 kg of pulp mixture, enough to make one meter of paper. While lotus stems are relatively inexpensive, the labor-intensive processes involved in making lotus paper cost around 110,000 VND per square meter. According to the research team, most of the processes can be mechanized to increase productivity and reduce costs. The team is currently ordering a pulping machine.

Dried lotus leaf paper. Photo: Ngoc Tai

Soon, young people will implement a pilot model before transferring the production process to lotus-growing households, producing finished products or pulp for sale to paper manufacturing companies. One souvenir business selling lotus-based products has been selling lotus-themed paper bags since November.

According to Ms. Phuong, while production is not yet on an industrial scale, people can utilize their free time during the agricultural off-season to earn extra income. In addition, through trade promotion opportunities, the group introduces lotus paper to packaging processing businesses, art and gift companies, seeking long-term outlets...

The group is developing and implementing a lotus paper-making experience for tourists visiting Dong Thap, both to develop tourism and to create an outlet for products made from lotus. These young people hope that lotus paper will contribute to completing the value system of the lotus industry in Dong Thap province in the context of green transformation and circular economy .

Besides lotus paper, many young entrepreneurs in Dong Thap have successfully commercialized various lotus-based products such as lotus tea (made from lotus leaves and hearts), bottled beverages, processed foods made from lotus seeds and roots, lotus leaf bags, souvenirs, perfumes, and essential oils.

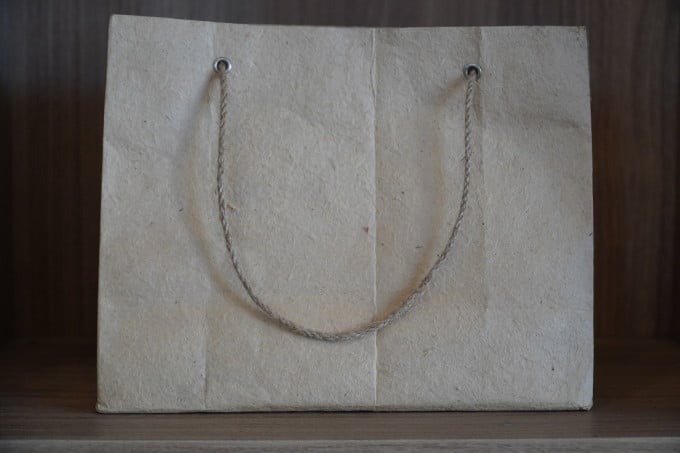

Paper gift bags made from lotus stems. Photo: Ngoc Tai

Mr. Le Quoc Dien, Deputy Director of the Department of Agriculture and Rural Development of Dong Thap province, said that lotus paper is a circular product in the lotus value chain. Currently, all parts of the lotus plant, from leaves, stems, seeds, and tubers, are not wasted.

"Farmers have additional income, which helps them become more attached to this agricultural product," he said. Dong Thap has more than 1,200 hectares of lotus, with a yield of 900 kg of lotus seeds per hectare, and 49 processed lotus products have received OCOP certification (One Commune One Product according to the standards of the Ministry of Industry and Trade).

Ngoc Tai

Source link

![[Photo] General Secretary To Lam working with Ambassadors and Heads of Vietnamese representative offices abroad attending the 14th National Congress of the Party](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2026%2F01%2F25%2F1769327811288_a1-bnd-4520-9649-jpg.webp&w=3840&q=75)

Comment (0)