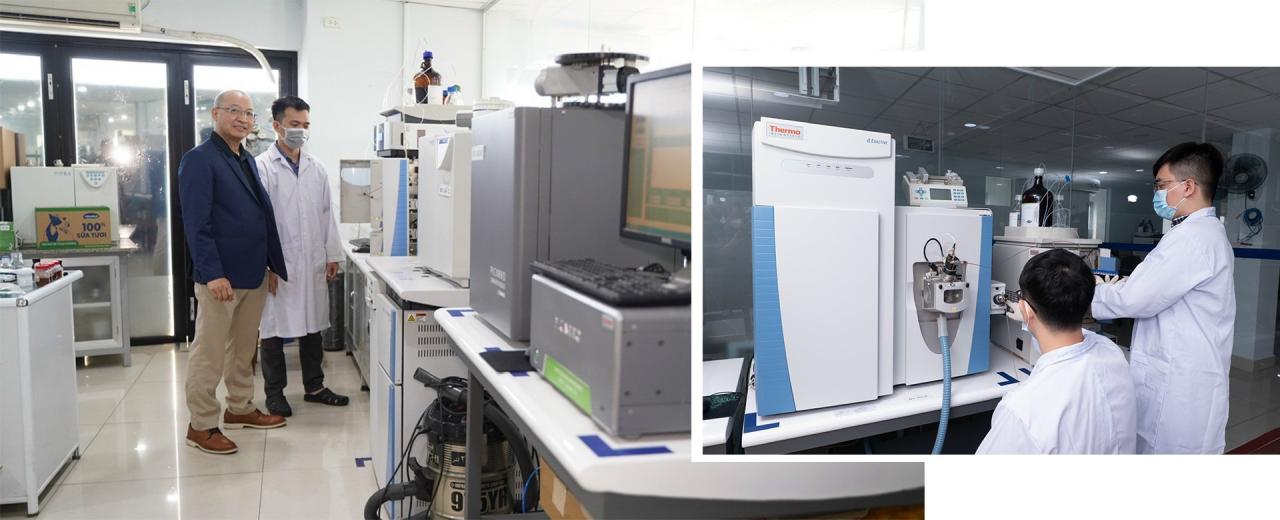

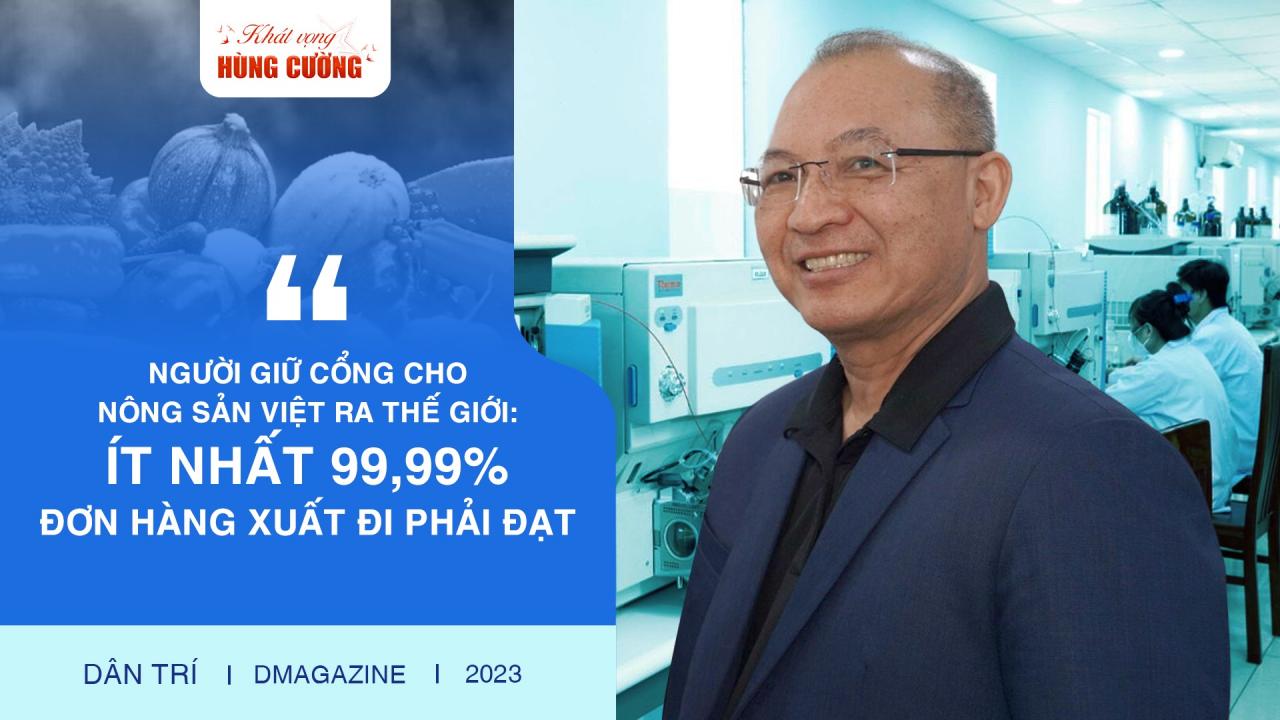

As an engineer with 30 years of experience working at the most prestigious university in the United States, Stanford, and leading technology companies such as Thermo Scientific, Agilent Technologies, and participating in the invention of some aspects of modern mass spectrometry technology... Mr. Henry Bui (General Director of the Hoan Vu Testing Center) decided to give up everything and return to Vietnam for one reason: to help Vietnamese people eat clean food.

After 16 years of establishment, Hoan Vu is inspecting 50,000 tons of honey/year exported to the US, more than 3,000 batches of dragon fruit to markets, including 2,700 batches of dragon fruit/year to the EU.

In addition to the domestic market, Mr. Henry Bui also received requests to authenticate other goods before exporting from countries such as Thailand, Korea, the US, Argentina, India...

Few people know that to achieve the above success, this Vietnamese American man had to go through many difficulties.

In early September, Dan Tri reporter had a meeting with Mr. Henry Bui. A special interview took place in the lab, when the indexes and information on Vietnamese passion fruit exports continued to be transmitted to Europe.

Hello! Vietnamese people always say that America is one of the most demanding markets in the world . From the perspective of an expert in the lab that assesses the quality of agricultural products exported to America, do you think it is an easy or difficult market?

- Oh my god! In fact, America and Europe are very easygoing countries.

They respect sellers, orders and businesses that export items that want to enter their country. As long as we state the purpose of use and clear specifications, it is completely simple.

The question is whether we can fully meet their requirements.

Previously, many Vietnamese agricultural products were still warned when exported abroad. What do you think about this?

- The current difficulty is that some Vietnamese people are still ambiguous about honesty.

If at first Europe only checked at a low level, 5% or 10%, we could easily get away with it and help the whole industry get approved. But when our country exports a large quantity, Europe raises the inspection level to 50% then 60%, and when impurities are discovered, they immediately ban the whole industry.

You have to understand, Vietnam is the same. How can you just dump your own garbage in front of someone else’s house? It’s easy to get into Europe, but their technical barriers are extremely high, whether you can overcome them or not is another story.

So, at the end of 2018, when impurities were discovered on large dragon fruit, Europe issued a ban on Vietnam, creating an immediate crisis.

The re-examination process takes 4 days. If the documents are not prepared properly, the cost of bringing them back to Vietnam will increase and put them on the brink of bankruptcy.

At that time, countless customers came to us. They did not care whether we checked correctly or not, just asked us to check again if it did not pass.

There was even a partner who brought dragon fruit samples for inspection 5 times and failed all 5 times. On the 6th time, in order to export the goods, they were willing to ask me to "support the cost".

How did he respond in that situation?

- "If you want it easy, go somewhere else" - I replied.

There was a case where I discovered a business owner using Chinese goods disguised as Vietnamese goods for export. I called him out directly: "By doing this, you are killing the entire agricultural sector."

We export for thousands of batches, for the long-term development of Vietnam, not just once!

I promise if we pass it we can absolutely enter countries around the world.

But Hoan Vu is wrong, but in case you mix it wrong, leading to unsatisfactory results, there is no way I can save you. I don't want to make things difficult for anyone, I just want to help them, but how can I let poor quality products pass?

During the following week, our entire lab quickly resolved the legal issues, sending all the documents to Europe for the companies to use as standards. We examined each container to check for food safety.

On the 8th day, news came back from Europe that Vietnamese dragon fruit could continue to be exported. The whole lab hugged each other and cried with joy.

Because you know what? Because the numbers we give are accurate to five decimal places and match exactly what Europe has checked.

How important is the accuracy down to the smallest number in opening the door for Vietnamese agricultural products to go abroad, sir?

- "What percentage of shipments would make you happy?" - the first time I returned to Vietnam, I also asked the engineers the same thing.

"95%," they answered in unison.

"95% we lost" - I replied to everyone's bewilderment.

You try to calculate, 100 orders, according to the index 95%, there will be 5 orders dropped. Just multiply that by the quantity of 50,000 tons that Hoan Vu makes each time, how much will it be, and multiply it by the whole Vietnamese agricultural industry?

Every year we export 200 shipments, but if 6 or 7 shipments fail, the association will ban them, and the business will lose money. Moreover, the process of importing back to Vietnam increases the cost by a hundred times. Therefore, talking about 95% of the shipments passing the test means bankruptcy.

For me, every export order must always reach 100% or at least 99.99%. That number is the company's requirement and also the pressure I put on myself.

Has your company ever been in the 0.01% error situation?

- Yes! It was a very painful lesson!

In 2020, we opened the way for Vietnamese honey to be sent to the US and UK. During the testing process to review the standards, we went through countless filtering and filter observation lines.

However, when the product arrived in the US and UK, it was immediately warned and returned.

That whole week, I lost sleep and appetite, because Hoan Vu's order had been through many countries and had never had any mistakes, so it was almost a crisis.

I sat down with our foreign partners to find the reason. The entire Vietnamese engineering team jumped in to work from scratch, extracting tens of thousands of parameters to find the answer. Furthermore, we also committed to taking part of the damage and compensation responsibility.

Only when the source was traced back and the imported filter sample was found to be contaminated from the beginning, it sank to the bottom without anyone noticing, did everyone dare to breathe a sigh of relief.

But even in danger there is opportunity. It is this professional and serious working attitude that makes the US highly appreciate Vietnam's lab capacity.

What is the danger?

- Up to now, we have not made a single mistake in the comparison results at the US lab. That helps us become a lab with enough basis to approve honey to enter the US.

Even around 2019-2020, information that honey could be counterfeited and undetectable caused Europe to jump up.

Luckily, at that time, we, along with Duc, were the only units that had implemented a traceability system within the ingredient solutions. We researched and built "sugar markers - sugar maker", accurate to 5 odd numbers, separating more than 3,000 different substances. This is the reason why our honey analysis results were accepted by demanding markets.

Is that belief in Vietnamese agricultural products the reason why you decided to give up everything to return 17 years ago?

- In 2006, I happened to read an article: "Muddy water in the city" published in a newspaper. At that time, the concern about why somewhere in my hometown there was still the scene of drinking dirty water and eating unclean food kept urging me.

During the early years, I traveled back and forth between the US and Vietnam to build labs and teach food safety and hygiene programs to engineering students.

I just think this, if someone had helped Vietnam on the above issue, maybe I wouldn't be here today. If not, I would return.

When you first returned, what did you see in the picture of Vietnamese agriculture?

- Vietnam's agricultural production industry has great potential thanks to its favorable climate and vast resource areas, which is confirmed by the hundreds of businesses that are qualified to export agricultural products internationally. However, it still has many difficulties.

Firstly, our production is still small-scale and fragmented, and we do not own large-scale agriculture, so it is difficult to control and manage.

Second, farmers' awareness is still lacking, often harming themselves for immediate benefits.

Third, regarding food safety, we lack guidance for farmers. Many times they spray pesticides indiscriminately without knowing the source, wanting the plants to grow but using all kinds of chemicals.

Fourth, the country itself still lacks a market for its products, which creates many consequences for the export process.

Over the past 16 years, besides being the "gatekeeper" for agricultural products to enter demanding markets, what have you done to help Vietnam's clean agriculture path?

- Honestly, the concern of how to make Vietnamese people eat cleanly still reminds me every day.

Because I am a foreigner, I have witnessed the difficult technical barriers of countries around the world. So we should not think about bringing our garbage to their country or allowing ourselves to continue using it.

I am working with Vietnamese scientists to research biological pesticides. This is a large agricultural project that only three countries, the US, Australia and Switzerland, have the product, but it is very expensive.

As for this route, we are still in the testing phase.

Finally, do you have any wishes for your path of serving Vietnam?

- We are a large company, owning a large-scale lab in Southeast Asia, but we have only used 1/4 of our efforts.

I hope that in the future, this will be the address of businesses that need accurate results, and the only place that gives accurate results down to the numbers so that not only agricultural products but we also pave the way for products with Vietnamese reputation such as honey powder, passion fruit juice, pineapple juice, sugarcane...

In addition, I still believe that if I were chosen to return to Vietnam to carry out this mission, then for the rest of my life, I would create a generation that would join hands for the development of the food safety and hygiene industry.

And the proof is the dozens of engineers you see working hard in this lab today… (laughs).

Content: Huy Hau

Design: Minh Ngoc

Photo: Character provided

Dantri.com.vn

![[Photo] Cutting hills to make way for people to travel on route 14E that suffered landslides](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/08/1762599969318_ndo_br_thiet-ke-chua-co-ten-2025-11-08t154639923-png.webp)

![[Photo] "Ship graveyard" on Xuan Dai Bay](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/08/1762577162805_ndo_br_tb5-jpg.webp)

![[Video] Hue Monuments reopen to welcome visitors](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/11/05/1762301089171_dung01-05-43-09still013-jpg.webp)

Comment (0)