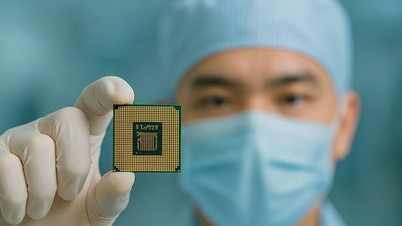

A group of researchers in China has just announced a new method capable of "reviving" exhausted lithium-ion batteries, thereby opening up the prospect of significantly reducing the amount of electronic waste from electric vehicles and the need to produce new batteries.

“This work is revolutionary because it offers a new idea for reusing batteries that have reached the end of their life cycle,” said professor Jiangong Zhu from Tongji University in Shanghai, who specializes in electric vehicle batteries and was not involved in the new study, which was recently published in the journal Nature .

According to the United Nations Development Programme (UNDP), the amount of spent lithium-ion batteries that need to be disposed of could skyrocket from 900,000 tonnes this year to 20.5 million tonnes by 2040. As a world leader in electric vehicle deployment, China currently processes about 2.8 million tonnes of waste batteries each year, according to Huang Jianzhong, chairman of the China Electronic Energy-Conserving Technology Association.

Faced with the prospect of rapidly increasing consumer markets and waste, chemist Yue Gao at Fudan University and his colleagues predicted a huge demand for disposal of batteries, especially electric vehicle batteries.

Typically, electric car batteries reach their limit of use—that is, their capacity drops below 80 percent of its original—after about eight to 10 years of operation. The cost of the battery accounts for about 40 percent of the total cost of the vehicle.

Gao’s team wanted to find a molecule that could “transfer” lithium ions back into a depleted battery. “We had absolutely no idea what kind of molecule could do that, or what its chemical structure would be. So we turned to artificial intelligence to help us,” said Chihao Zhao, a PhD student at Fudan University who is part of Gao’s team.

The team used an AI model trained on chemical laws, combined with a database of electrochemical reactions, to find molecules that met the criteria: easy to dissolve in electrolyte solutions and low production costs. As a result, the AI proposed three candidates, of which a salt called lithium trifluoromethanesulfinate (LiSO₂CF₃) was identified as optimal.

The researchers tested this lithium-ion salt by dissolving it in an electrolyte solution—the medium that allows ions to move between the battery’s electrodes. Gao likened the method to giving an IV to a patient. “If we can inject a drug to help a sick person recover, why can’t we give the same ‘elixir’ to a depleted battery?”

The results showed that the compound could significantly extend the life of lithium iron phosphate (LFP) batteries, which are commonly used in electric vehicles. A typical LFP battery can be charged and discharged about 2,000 times before it is considered “dead.”

However, by adding electrolyte solution when the battery was about to reach this threshold, the team was able to restore much of the battery’s capacity – leaving it functioning almost like new. At the end of the experiment, the battery had 96% of its capacity after nearly 12,000 charge-discharge cycles.

A further test showed that this method also works with NMC (nickel, manganese and cobalt) lithium-ion batteries.

Fudan University is now working with battery materials maker Zhejiang Yongtai in China to commercialize the technology. Gao envisions the collaboration leading to a system of “battery boost stations” where electric vehicle owners can bring in old batteries for reconditioning.

The idea is “promising,” said Chenguang Liu, a professor at Xi’an Jiaotong University in Liverpool. But he noted that the new method still faces some challenges, such as ensuring compatibility with different battery chemistries and, more importantly, testing the safety of the resurrected batteries.

In addition, the power source of an electric vehicle is not just a single battery but a system of hundreds or even thousands of batteries, combined with thermal control systems and other complex components. “Right now, we are only testing single batteries, so we need to find a way to apply it to the entire battery pack,” Gao said.

Gao’s method is one of the closest approaches to “direct recycling” of electric vehicle batteries in China, according to Hans Eric Melin, managing director of London-based consultancy Circular Energy Storage.

Melin says the approach could have commercial potential — though the market may not be huge, given that electric car batteries last up to 15 years. He also points out that battery packs in electric cars would need to be redesigned to allow for electrolyte injection.

“The question is whether the benefits are large enough to justify the design change, which could impact the overall performance of the battery,” he said.

(Vietnam+)

Source: https://www.vietnamplus.vn/tri-tue-nhan-tao-tim-ra-tien-duoc-co-kha-nang-hoi-sinh-pin-da-can-kiet-post1043216.vnp

![[Photo] President Luong Cuong attends special political-artistic television show "Golden Opportunity"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/22/44ca13c28fa7476796f9aa3618ff74c4)

![[Photo] President Luong Cuong receives delegation of the Youth Committee of the Liberal Democratic Party of Japan](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/22/2632d7f5cf4f4a8e90ce5f5e1989194a)

![[Photo] Prime Minister Pham Minh Chinh chairs the conference to review the 2024-2025 school year and deploy tasks for the 2025-2026 school year.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/22/2ca5ed79ce6a46a1ac7706a42cefafae)

Comment (0)