EFFECTIVENESS FROM CONVERSION

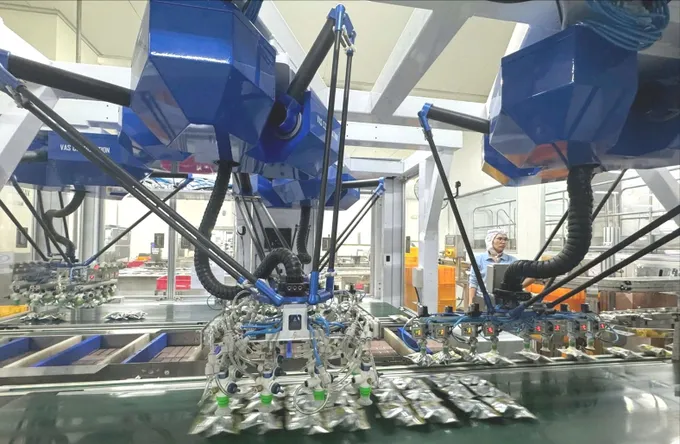

Recounting the story of implementing the smart factory project, Mr. Jeong Jong Yeon, Deputy General Director of Orion Vina Food Co., Ltd., said that the company implemented the project by applying a digital transformation production process associated with green and smart manufacturing at its factory in My Phuoc 2 Industrial Park, Ben Cat Ward. The smart factory project is divided into 3 phases (starting from April 2024 to March 2026). The solutions applied by Orion Vina include: building an Intelligent Operation Center (IOC), automation technology (robotics), Industrial IoT technology, etc.

“After approximately eight months of implementing Phase 1, the smart factory project has brought clear benefits to Orion Vina in many aspects, from operational efficiency and cost reduction to sustainable production orientation and management modernization,” Mr. Jeong Jong Yeon shared. Specifically, in terms of efficiency, the smart factory system helps increase production capacity by 30% and reduce downtime by 68% thanks to real-time monitoring, incident prediction, and process optimization. Economically , the project is estimated to yield a profit of approximately $19 million in the initial implementation phase alone. Inspection costs have decreased by 50%, while energy and operating costs are better controlled.

As one of the businesses accelerating automation in its production facilities, Mr. Vu Anh Tuan, Senior Vice General Director of CP Vietnam Livestock Corporation, stated that the Hai Duong factory (one of CP Vietnam's largest animal feed production plants in the North) has a fully integrated production line that includes grinding, mixing, pelletizing, cooling, and packaging, along with robotic loading and unloading of finished products and an automated control system. The Control Room monitors in real time, maintaining a stable productivity of 800-850 tons per shift, reducing manual labor, and increasing safety and operational efficiency. Furthermore, the factory possesses a Feed Technology laboratory and a sampling, coding, and quality verification system to ensure objectivity and quality for each batch of goods.

Speaking at the Smart Factory 2025 conference in Ho Chi Minh City at the end of October, Mr. Pham Van Viet, Chairman of the Board of Directors of Viet Thang Jean Co., Ltd., said that the factory was built on a smart supply chain platform from raw materials, design, production to distribution. Everything is connected by data. The company has applied 3D design, automated cutting, smart warehousing, and modern machinery systems to create a seamless production line. The application of technology and data connectivity helps the business flexibly meet large and small orders and comply with the stringent emission standards of the European market.

OVERCOMING BARRIERS IN AI APPLICATIONS

The effectiveness of promoting automation and applying AI to manufacturing has been gradually proven. However, according to surveys, the percentage of Vietnamese businesses applying AI is currently only about 18%, significantly lower than Thailand (25%) and Singapore (40%). According to experts, human resources and data are the biggest barriers to bringing AI into manufacturing. Associate Professor Ali Al-Dulaimi, Head of the Department of Computer Science and Technology, British University Vietnam, believes that building a database infrastructure is a crucial factor for the success of AI application in manufacturing.

Sharing specific directions for businesses, Dr. Duong Hong Loan, Senior Strategy Advisor at the British University Vietnam and Director of the Vietnam Institute for Innovation, suggested that for small and medium-sized enterprises (SMEs), the AI deployment strategy should focus on practical, cost-effective solutions such as AI chatbot applications in customer service, inventory management, demand forecasting, and data analysis to support decision-making. For large-scale businesses, the strategy should aim for comprehensive automation, intelligent quality control, real-time data processing, and financial risk management, thereby building a data-driven overall management strategy.

It's also worth noting that when discussing human barriers, it's not just leaders who think "small businesses find it difficult to apply AI," but even within the workforce, there are still misconceptions that AI will take all their jobs. In reality, AI doesn't replace humans; humans are simply replaced by skilled AI users. That's why improving the quality of human resource training to master the technology is one of the key factors for success when applying AI in production.

Returning to the business reality, when asked about the challenges in implementing the smart factory project, the Deputy General Director of Orion Vina stated that the biggest difficulty came from upgrading a factory that had been operating for nearly 30 years to a smart factory model, while simultaneously changing the mindset and working methods of the staff from manual operation to data-driven management.

According to sggp.org.vn

Source: https://baodongthap.vn/tang-toc-dau-tu-nha-may-thong-minh-a234976.html

![[Photo] Prime Minister Pham Minh Chinh receives Canadian Minister of International Development Randeep Sarai](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2026%2F01%2F06%2F1767708661052_image123-3433-jpg.webp&w=3840&q=75)

![[Image] Fifth meeting of the Steering Committee for National Projects in the Railway Sector](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2026%2F01%2F06%2F1767712857541_ndo_br_dsc-0581-jpg.webp&w=3840&q=75)

![[Infographic] Sa Dec Flower and Ornamental Plant Festival II, 2025: Impressive Figures](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2026/01/06/1767708639260_infographic-festival-hoa-kieng-sa-dec-lan-thu-ii-nam-2025-nhung-con-so-an-tuong20260106081659.webp)

Comment (0)