The research involved Dr. Pham Le Nhan, a specialist in inorganic materials and materials applied in biotechnology. He previously conducted research and taught in Vietnam .

Thermal and infrared imaging are used in many industries such as defense, security and surveillance, medicine, electrical engineering, space exploration, and autonomous vehicle operations. However, the materials used in this technology are expensive and increasingly difficult to find. To meet the need for low-cost alternatives, a team of chemists and physicists at Flinders University has developed a completely new polymer material made from sulfur and cyclopentadiene (C5H6). These high-performance polymers have exceptional capabilities in transmitting infrared light.

Speaking to Thanh Nien newspaper , Dr. Nhan said the new material is based on a reaction between sulfur and cyclopentadiene, creating a black plastic with high transparency to infrared light. "This is the light detected by thermal imaging cameras. This new material is designed for many potential applications, from aerospace engineering to military operations, as well as civilian and aerospace industries," according to Dr. Nhan.

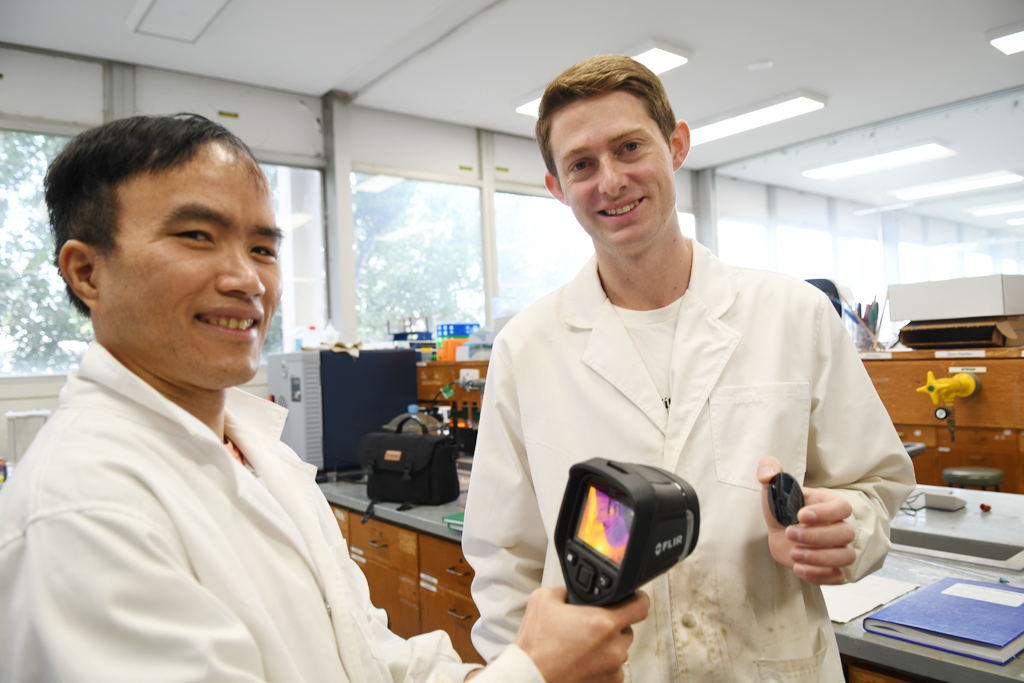

Dr. Nhan and Dr. Tonkin (right)

The new material can be molded into various types of lenses, including those used to magnify images in thermal imaging cameras. Its black color also helps conceal and protect the device, making it suitable for camouflage—a useful characteristic in defense operations or wildlife tracking.

In the journal Advanced Optical Materials, co-author Dr. Sam Tonkin of Flinders University stated that the new material "has the potential to expand the use of thermal imaging to new industries previously limited by the high cost of germanium or chalcogen lenses."

Sulfur is produced in millions of tons in the oil refining industry, not to mention billions of tons available in geological deposits. In addition, cyclopentadiene is also derived from inexpensive materials produced during oil refining. Meanwhile, current thermal imaging lenses use germanium, a material with very limited supply and therefore very expensive. Some germanium lenses can cost thousands of dollars. Chalcogen lenses also have drawbacks, such as the use of toxic components like arsenic or selenium.

The new polymer material also possesses many other properties, such as the highest transparency ever recorded for a plastic to long-wavelength infrared light. The raw material is also low-cost, with 1 gram of lens costing less than 1 cent. Furthermore, this material can be rapidly molded to create a variety of shapes.

Source link

![[Photo] Prime Minister Pham Minh Chinh presides over the conference announcing the establishment of the International Finance Centre in Vietnam.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F21%2F1766309817714_ndo_br_dsc-3400-jpg.webp&w=3840&q=75)

![[Photo] Prime Minister Pham Minh Chinh presides over a meeting on private sector economic development.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F20%2F1766237501876_thiet-ke-chua-co-ten-40-png.webp&w=3840&q=75)

Comment (0)