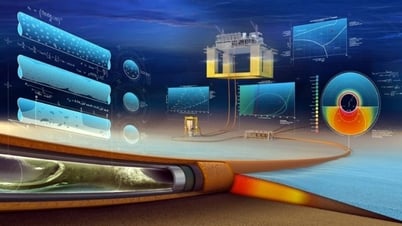

Shenzhen, China-based robot company UBTech says its humanoid robot Walker S2 can automatically complete a battery change in less than three minutes without shutting down.

Accordingly, the Walker S2 robot is capable of self-monitoring energy levels and automatically changing batteries when necessary. Equipped with energy balancing technology and a battery designed to be plugged in like a USB device, the robot can easily insert and remove batteries. Applying this technology helps prevent work interruptions due to battery charging time, while reducing labor maintenance costs and improving overall production efficiency.

Walker S2 is the world's first humanoid robot capable of automatically changing batteries, supporting continuous work 24/7. (Source: Reuters)

UBTech has not set a goal of mass producing this robot, but its Walker robots have been tested on production lines at several factories of Chinese electric car companies BYD, Nio and Zeekr.

"Previously, a major weakness of robots was their limited operating time, usually only about four hours. This battery replacement technology effectively solved that problem. Otherwise, the robot would have to pause to recharge before it could continue working, while the production line could not stop. Therefore, this technology allows robots to work continuously, opening up the possibility of making humanoid robots standard equipment in factories and production lines," said Fan Congming, Vice President of the Shenzhen Artificial Intelligence Industry Association.

The application of robots in production lines is accelerating the process of upgrading automation in factories. Since the beginning of the year, many humanoid robot companies in China have received orders from automobile manufacturers. Robots' work mainly includes transportation and quality inspection in fields such as automobile and electronic equipment manufacturing. Technological breakthroughs in energy solutions have helped robots operate more stably and for longer periods of time, thereby enhancing safety and reliability in factory work.

“Companies are now moving towards smarter manufacturing processes. In industrial manufacturing, tasks such as moving, polishing, welding, spray painting, as well as heavy lifting and stacking in the automotive industry are repetitive and labor-intensive, so we use robots to replace humans,” said Xing Fan, a production manager at a robot factory in Foshan, China.

According to a report on the humanoid robot industry released at the 2024 World AI Conference in Shanghai, the scale of China's humanoid robot market in 2024 reached about 2.76 billion yuan (about 381.28 million USD), and is expected to increase to 75 billion yuan (about 10.36 billion USD) by 2029.

China now ranks third in the world in terms of robot usage in the manufacturing sector, behind only South Korea and Singapore.

Source: https://vtcnews.vn/khong-can-tat-may-robot-tu-thay-pin-chi-trong-3-phut-ar956086.html

Comment (0)