Strict requirements on quality and sustainability from export markets are a big challenge for Vietnamese tablet production - Photo: VGP/Do Huong

Demand remains high in key markets

Japan and South Korea continue to be the two main export markets for Vietnam's pellet industry. In 2024, Japan accounted for 60% in volume and 65% in value, while South Korea contributed 34% in volume and 28% in value. The average export price reached 144.3 USD/ton in Japan and 109.2 USD/ton in South Korea, respectively. Notably, from September 2024, pellet prices to South Korea increased significantly due to improved bidding prices and a shortage of wood processing materials. This shows that demand in this market remains high, despite increasing competitive pressure.

Reliance on these two markets offers the advantage of geographical proximity and favorable biomass energy policies, but also carries risks as demand may fluctuate based on global energy policies or trends. Double-digit growth in the first half of 2025 shows that the pellet industry is taking advantage of the opportunity from renewable energy demand, especially as countries push to reduce emissions.

Dr. To Xuan Phuc, policy analyst at Forest Trends, said that despite contributing nearly $1 billion each year to wood export turnover, the pellet industry still faces serious barriers.

The first challenge is the dependence on secondary supply from other wood processing industries, instead of having its own raw material areas. This makes pellet production vulnerable to seasonality, waste prices and supply instability, especially as demand in Japan grows.

Second, product quality is a hot issue. Although businesses have made efforts to reduce impurities, chemical and metal residues in pellets are still a major obstacle, directly related to input materials. Mr. Nguyen Thanh Phong, Chairman of the Vietnam Pellet Association, said that removing the bark can meet quality standards, especially in Japan, but will push up production costs, far exceeding the current export price (about 144 USD/ton), making it difficult for businesses to maintain operations.

Third, strict requirements on quality and sustainability from export markets are a big challenge. South Korea has recently tightened quality standards, pushing up export prices, while Japan requires FSC and PEFC certifications and is gradually applying SBP certification for low-emission supply chains. In the future, Japan may follow the EU example with the EU Deforestation Reduction Regulation (EUDR), which requires strict traceability, something that many Vietnamese businesses are not ready to meet.

Fourth, dependence on Japan and South Korea is a big risk. These two markets account for nearly 94-96% of total export volume and value, but if policies change or competition increases, the Vietnamese pellet industry may fall into a passive position.

Finally, the lack of linkages and industry development strategies is a weakness. The industry currently has a large division between large enterprises (accounting for 70% of exports) and small-scale establishments. Fierce competition for raw materials and customers, along with dumping in Korea, has caused tablet prices to hit rock bottom, causing losses for many enterprises.

Vietnam’s pellet industry is not only facing internal challenges but also pressure from new competitors such as Thailand, Indonesia and Malaysia. These countries provide pellets with higher quality and competitive prices, threatening Vietnam’s position in Japan and South Korea. In the short term, long-term contracts help Vietnamese businesses maintain stability, but in the long term, if quality is not improved and sustainability standards are not met, the industry may lose its advantage.

Dumping, especially in South Korea, has damaged the reputation of the Vietnamese pellet industry. Pellet prices lower than production costs in 2023 have pushed many businesses into difficulties, creating a precedent of unfair competition. This not only affects the national image but also reduces the value of Vietnamese pellets compared to regional competitors.

Mr. Tran Quang Bao, Director of the Department of Forestry and Forestry ( Ministry of Agriculture and Environment ) acknowledged that currently, the Forestry sector is implementing the policy of promoting the development of groups of deeply processed forest products with high added value, including main products such as: Wooden products; finger jointed boards; plywood, particle boards; MDF boards; wood pellets, wood chips ...

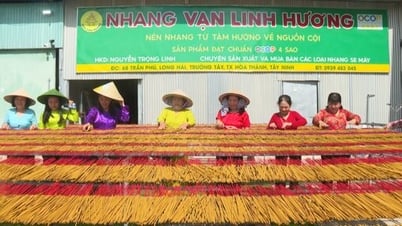

Processing and producing wood pellets is in line with the Circular Economy Development Project in Vietnam because the raw materials for producing wood pellets come from by-products of the exploitation and processing of forest products such as sawdust, branches, and twigs of trees after exploitation (the remaining part is not used as raw materials for processing products other than pellets...) increasing the value of using planted forest wood.

In 2024, Vietnam and Japan signed a Cooperation Agreement in the Forestry sector between the Vietnam Forestry Department (now the Department of Forestry and Forestry) and the Japan Forestry Agency, including cooperation on sustainable forest management, ensuring legal wood materials and trade, so the use of raw materials for production and processing of wood pellets must be guaranteed to come from legal sources according to national regulations.

Dr. To Xuan Phuc recommends that businesses invest in building their own raw material areas, reducing dependence on secondary sources and meeting legality and sustainability requirements. Some businesses are pioneering in applying group forest certification, targeting more demanding markets, but high costs require stable output in terms of price and purchasing power. A cooperative ecosystem between businesses, using shared sustainable raw materials for many products, is a feasible direction.

On the macro level, there needs to be supportive policies such as planning the pellet industry in the wood ecosystem, giving incentives to biomass energy and controlling unfair competition. This will create a sustainable development environment, helping businesses compete effectively both domestically and internationally. Improving quality, building brands and diversifying markets outside of Japan and Korea (such as the EU) are strategic steps for the pellet industry to assert its position.

Do Huong

Source: https://baochinhphu.vn/vien-nen-go-chuan-hoa-san-xuat-de-dap-ung-nhu-cau-thi-truong-102250711140753036.htm

Comment (0)