Finland Scientists have created a new material consisting of an outer layer made of water-repellent molecules, bonded to a solid silicon surface underneath.

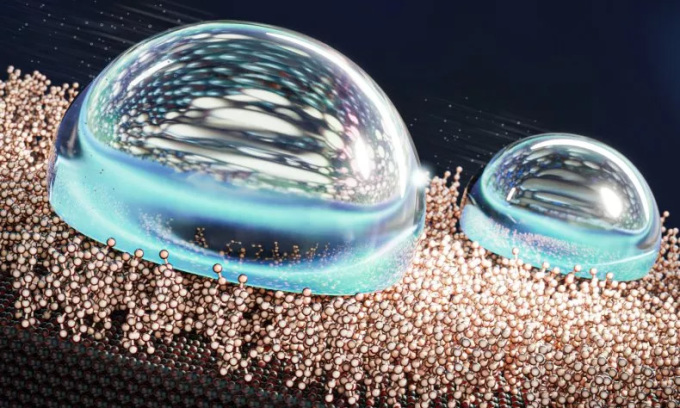

Illustration of a liquid-like molecular layer repelling water droplets. Photo: Ekaterina Osmekhina/Aalto University

A Finnish research team led by Robin Ras at Aalto University and supported by scientists from the University of Jyväskylä has developed a mechanism that makes water droplets slide off surfaces with unprecedented efficiency. The new study was published in the journal Nature Chemistry on October 23.

The way water adheres to or slides off surfaces affects cooking, transportation, optics, and hundreds of other technologies. Better water-resistant surfaces could improve many technologies used in homes and industries, such as plumbing, transportation, and automobiles.

In the new study, the team created solid silicone surfaces with a liquid-like outer layer that repels water by allowing water droplets to slide off the surface. This coating acts as a lubricant between the product and the water droplets.

The new findings challenge current ideas about the friction between solid surfaces and water, opening up new possibilities for studying slipperiness at the molecular level. "Our study is the first to go straight down to the nanometer scale to create molecularly heterogeneous surfaces," said Sakari Lepikko, a member of the research team.

By carefully adjusting factors such as temperature and water content in the reactor, they were able to control the extent of coverage of the self-assembled monolayer (SAM) on the silicon surface. Surprisingly, even low coverage resulted in extremely high slipperiness.

Using their new method, the team created the world's most slippery liquid surface. According to Lepikko, the discovery promises applications wherever a waterproof surface is needed. "It has potential applications for heat transfer in pipes, de-icing, anti-fogging, creating self-cleaning surfaces, even microfluidics - where droplets need to move smoothly," Lepikko said.

The team plans to continue testing and improving the SAM coating. “The main problem with the SAM coating is that it is very thin, so it easily disintegrates after physical contact. But studying it gives us the foundational science that we can use to create long-lasting, practical applications,” Lepikko said.

Thu Thao (According to Guardian )

Source link

Comment (0)