Garment production line at Hanoi Textile and Garment Joint Stock Corporation.

Proactively switch to green production

"Ready, proactive and determined to transform green, transform digitally from a sustainable development mindset", this orientation of Vinamilk has been concretized with clear results. In 2024, Vinamilk continues to maintain 3 carbon-neutral units, including two factories and one farm; the rate of green energy replacing nearly 89% of fossil energy in production; maintaining greenhouse gas measurement according to ISO 14064 standards for all factories nationwide.

Vinamilk's Production Executive Director and Net Zero Project Leader Le Hoang Minh shared that at farms, wastewater treatment technology creates biogas that not only helps regenerate water for irrigation and organic fertilizer for crops, but also utilizes methane gas to dry grass, heat water, etc. This effective circular economic model helps Vinamilk save hundreds of millions of VND each month.

To reduce its carbon footprint and move towards Net Zero, Vinamilk has installed solar power systems at all factories and farms. In addition, the company also uses biomass energy from sawdust, bagasse, etc. and compressed natural gas (CNG) to replace fossil fuels, helping to significantly reduce carbon emissions. As a result, 89% of fossil fuel energy at factories has been replaced by green energy - an impressive figure in the manufacturing sector.

Also one of the leading enterprises in green transformation, TH Group is persistently building a sustainable and environmentally friendly consumption journey. Since 2018, TH true mart has been one of the first retail systems in Vietnam to completely stop using plastic bags, replacing them with biodegradable bags, and encouraging consumers to use cloth bags. TH is also the first enterprise in the dairy industry to use yogurt spoons made from materials derived from plant starch, safe for users' health, replacing PE plastic spoons. From 2022, TH will reduce 50% of the number of spoons given away with yogurt products... With practical actions, TH Group has reduced about 600 tons of plastic and saved tens of billions of VND each year.

Similarly, many businesses have established dedicated research and innovation departments, creating a strong driving force for green transformation. A typical example is Vingroup, with large investments in VinFast electric vehicle projects, helping to reduce greenhouse gas emissions in transportation and develop renewable energy. Masan Group also implements initiatives to recycle plastic products, reduce waste and use green energy at manufacturing plants...

Comprehensive solutions are needed

According to Pham Hong Quat, Director of the Department of Startups and Technology Enterprises (Ministry of Science and Technology), businesses in Vietnam are making important strides in developing green technology solutions to protect the environment and promote sustainable development. However, businesses are also facing many difficulties, such as mobilizing finance for green transformation and unclear regulations for startups in this field.

To address these barriers, Mr. Pham Hong Quat said that management agencies need to survey, evaluate and build a map of the green innovation startup ecosystem in Vietnam; develop a framework for assessing the social - environmental - economic impact of green technology enterprises; support universities and research institutes to cooperate with enterprises to develop new green technologies. At the same time, communication campaigns on green consumption also need to be promoted to encourage consumers to use environmentally friendly products.

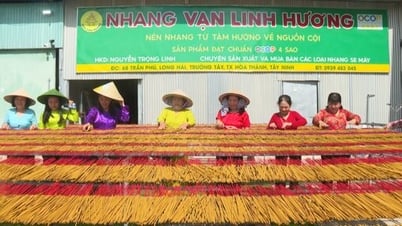

As one of the localities making drastic efforts in green transformation, by 2025, Hanoi strives to reduce 5-8% of raw material consumption in key manufacturing industries such as textiles, alcohol, beer, soft drinks, steel, and plastics. The city also aims to spread sustainable lifestyle and consumption throughout society. Accordingly, 100% of wards, communes, 100% of industrial zones and clusters and 70% of craft villages will be disseminated with knowledge and practices on sustainable production and consumption...

Director of the Hanoi Department of Industry and Trade Vo Nguyen Phong said that the Sustainable Production and Consumption Program in the capital is being implemented with many groups of solutions, from minimizing environmental impacts, using resources efficiently to forming a green economic model, circular economy. In particular, cleaner production and production of environmentally friendly products are promoted through building a network linking the product life cycle chain, from raw material suppliers to production, distribution and consumption.

Businesses in Hanoi are supported to assess cleaner production, access advanced techniques and apply management tools in sustainable production and consumption. Typical and effective models of resource-saving use will also be replicated. Regarding the distribution and import-export system, the City focuses on developing a network connecting retailers with suppliers of environmentally friendly products. Consumers are also clearly oriented through the dissemination of knowledge about organic products, eco-labeled products and criteria for choosing green products.

Source: https://hanoimoi.vn/chuyen-doi-xanh-dieu-kien-song-con-de-doanh-nghiep-ton-tai-va-phat-trien-709022.html

Comment (0)