Behind a heavily guarded door in a vast laboratory in the Netherlands, a giant machine is quietly reshaping the future of the global semiconductor industry. It is the High NA, the latest generation of EUV lithography equipment developed by ASML over nearly a decade. At a cost of over $400 million , it is the most advanced and expensive chip-making machine ever built.

High NA stands for High Numerical Aperture. This machine marks a revolutionary step forward for EUV lithography, which has helped the chip industry shrink electronic components to the nanoscale.

CNBC had a rare opportunity to visit ASML's Veldhoven lab in April. It was the first time High NA had been filmed, and even ASML's internal team had never seen the machine before.

Technology of the future

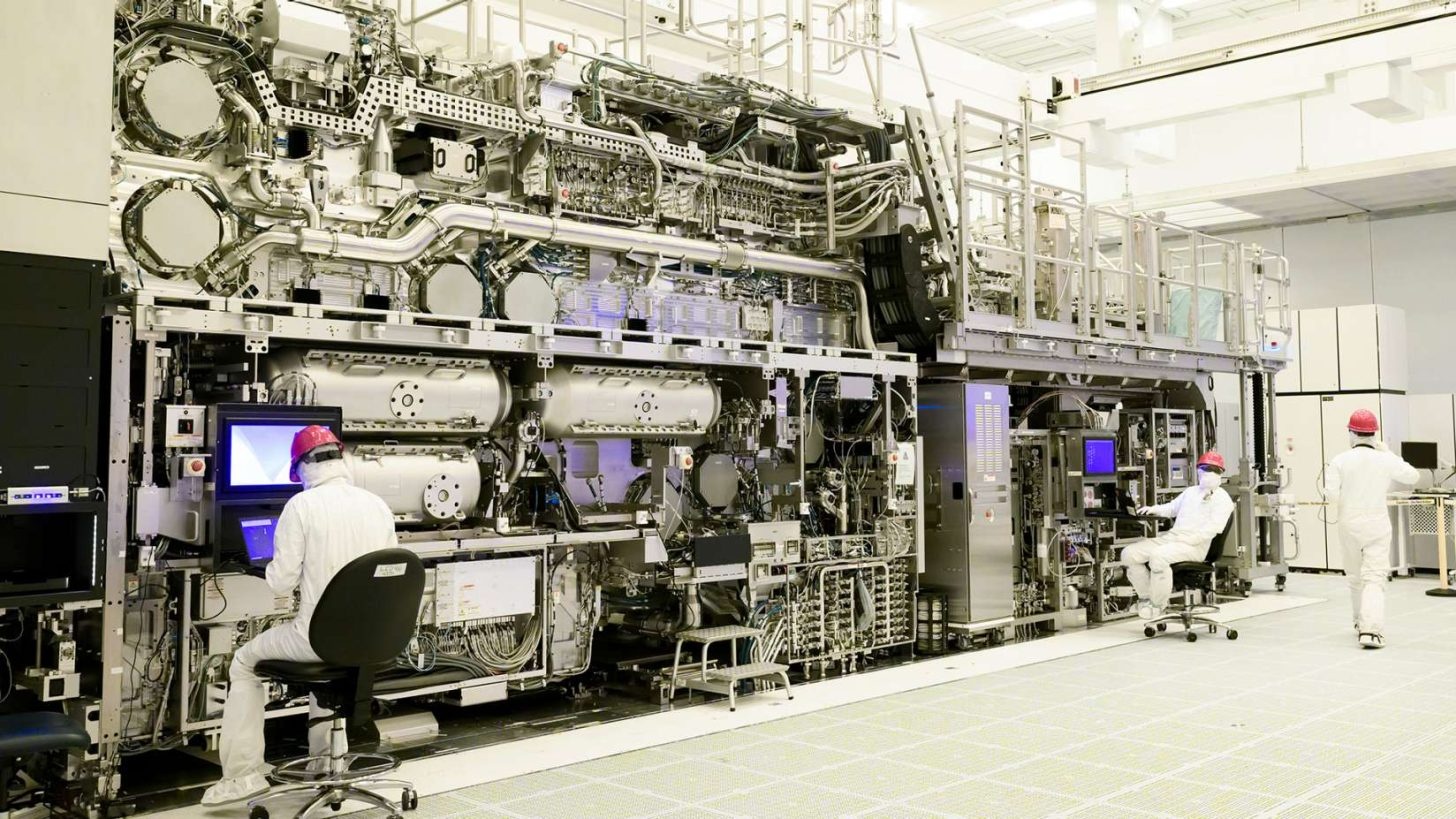

According to chief engineer Assia Haddou, the High NA machine is “bigger than a double-decker bus.” The device consists of four modules, manufactured at factories in Connecticut, California (USA), Germany and the Netherlands. After assembly and testing in the Netherlands, the machine is disassembled and shipped to customers.

The process requires at least seven Boeing 747s or 25 trucks, with the first being installed commercially at Intel's Oregon plant in the US in 2024.

|

The High NA machine is gigantic. Photo: CNBC . |

ASML is the only company in the world capable of making EUV lithography equipment. This technology allows for the projection of extremely small chip designs onto silicon wafers, a key process for manufacturing advanced chips. Leading companies such as Apple, Nvidia, AMD, as well as major chipmakers such as TSMC, Samsung, and Intel, all rely on ASML to create their products.

Additionally, the Netherlands-based company confirmed that all of its current customers will gradually transition to High NA, including Micron, SK Hynix, and Rap.

In addition to offering higher levels of precision, High NA also helps increase efficiency and reduce chip manufacturing costs. Intel says it has used the device to produce about 30,000 wafers, and it boasts twice the reliability of the previous generation of EUV. Samsung claims the device has reduced its production cycle time by 60%. According to Daniel Newman of The Futurum Group, ASML has completely dominated the chip lithography market.

“Moore’s Law says we need to keep reducing costs. There is a belief that if you reduce costs, you create more opportunities, so we need to be part of this game,” explained ASML CEO Christophe Fouquet.

Risky investment

High NA still uses the same EUV beam as previous generations, but the key difference is a larger lens aperture. This allows the device to capture more light from steep angles, allowing it to etch smaller designs onto the wafer in fewer steps. This brings two key benefits, according to ASML Executive Vice President of Technology Jos Benschop: miniaturization and increased productivity.

“High NA will bring two things. First and foremost is miniaturization. Second, by avoiding making many samples, you can make them faster and you can make them at higher yields,” says Jos Benschop.

Benschop, who joined ASML in 1997, played a key role in the decision to invest in EUV technology, a decision many at the time considered reckless.

|

Jos Benschop (right) shares ASML's vision. Photo: CNBC . |

“We barely made it. I think sometimes people forget that. It was a very risky investment because when we started, there was no guarantee that the technology would work,” CEO Fouquet added.

In 2018, ASML demonstrated the feasibility of EUV, paving the way for large-scale orders. The technology works by firing 50,000 tin droplets per second with a powerful laser, creating a plasma that emits EUV light with a wavelength of just 13.5 nanometers.

To operate the system, the entire process must take place in a vacuum environment because EUV is absorbed by all matter. In addition, special mirrors manufactured by the German company Zeiss play an important role in directing the light.

Geopolitical influence

Despite being known for its EUV technology, ASML still gets most of its revenue from previous-generation DUV machines. In 2024, the company sold 44 EUV machines and 374 DUV machines. China is the largest customer for these machines, accounting for 49% of Q2 2024 revenue.

However, due to the US export ban, ASML cannot continue selling EUV to China. Mr. Fouquet said that the Chinese operations will return to “pre-normal” levels, contributing 20–25% of the manufacturer’s revenue by 2025.

ASML currently has more than 44,000 employees worldwide, of which 8,500 are based in the U.S. The company is building a new training center in Arizona with the goal of training 1,200 engineers a year in EUV and DUV technology.

|

China is one of ASML's biggest customers. Photo: Bloomberg . |

In parallel, new High NA shipments are being shipped to Intel, a partner that Mr. Fouquet called “very important” to America’s technological independence, as the country pushes its semiconductor self-sufficiency strategy.

Not stopping there, ASML has already started work on the next generation, called Hyper NA. According to Mr. Fouquet, the engraver maker has some preliminary optical designs and it is not an impossible project. The company expects demand for Hyper NA to increase sharply around 2032-2035.

In the global race to shrink chips and increase performance, ASML technology is playing a central role, not only technically but also geopolitically. With High NA and its successors, the Dutch manufacturer is redrawing the boundaries of the microchip industry, a step that will shape the digital world for decades to come.

Source: https://znews.vn/co-may-400-trieu-usd-dinh-hinh-tuong-lai-nganh-chip-post1555116.html

![[Photo] Prime Minister Pham Minh Chinh chairs a meeting of the Government Standing Committee on overcoming the consequences of natural disasters after storm No. 11](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/09/1759997894015_dsc-0591-jpg.webp)

![[Photo] General Secretary To Lam visits Kieng Sang Kindergarten and the classroom named after Uncle Ho](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/09/1760023999336_vna-potal-tong-bi-thu-to-lam-tham-truong-mau-giao-kieng-sang-va-lop-hoc-mang-ten-bac-ho-8328675-277-jpg.webp)

![[Photo] President Luong Cuong attends the 80th Anniversary of the Traditional Day of Vietnamese Lawyers](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/09/1760026998213_ndo_br_1-jpg.webp)

Comment (0)