Potential "billion dollar" industry

According to the Ministry of Industry and Trade , the value of the mold and precision engineering industry in Vietnam is currently over 1 billion USD/year. In particular, with a growth rate of 18%/year, this industry is attracting the attention of many domestic and foreign enterprises.

|

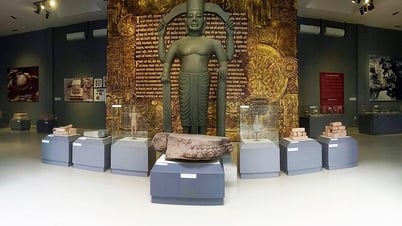

| Thaco industries focuses on investing in mold manufacturing, providing a variety of mold products to serve many different fields and industries. Photo: Thaco industries |

Notably, Vietnamese enterprises only make 8.5% of injection molds, the rest are stamping molds. Therefore, the demand for molds for plastic, mechanical, machine parts, components, etc. production to improve product quality is very large, helping domestic enterprises increase their capacity to participate in the global supply chain.

In fact, mold manufacturing is considered the future of the industry in general and the supporting industry in particular. According to a survey conducted by Samsung Vietnam and the Ministry of Industry and Trade, of more than 120 experts working in the mold industry, 50% were assessed as having only elementary qualifications; 39% had intermediate qualifications; only 11% had expert qualifications. Notably, none of the respondents had reached professional qualifications.

This shows the worrying reality of the mold industry's human resources in Vietnam today, with major shortcomings in both quantity and quality.

Meanwhile, improving the capacity of mold engineering means possessing an advanced manufacturing technique that helps optimize the quality of product processing for visual or tactile evaluation criteria on all plastic injection, pressure stamping or precision machining products; thereby contributing greatly to the industrial production sector of Vietnam, especially the production of hardware for electronic devices or for the motorcycle and automobile manufacturing industry.

In the context of mold engineering being considered the core engineering sector, the foundation of the manufacturing industry, the development and training of experts is extremely important. Moreover, improving mold engineering capacity helps optimize product processing quality for visual or tactile evaluation criteria on all plastic injection, pressure stamping or precision machining products. From there, it can contribute a lot to the industrial manufacturing sector of Vietnam, especially the hardware production for electronic devices or the motorcycle and automobile manufacturing industry.

As a large-scale mechanical and supporting industry manufacturing group, Thaco industries focuses on investing in mold manufacturing, providing a variety of mold products to serve many different fields and industries... Thaco industries produces a variety of mold types such as: Plastic molds, stamping molds, blow molds, extrusion molds, SMC molds, serving many fields: Automobiles, industry, agriculture, civil... in which, medium and large sized plastic molds are considered a strength, because most mold manufacturing units in Vietnam are limited in scale, technology, equipment, so they only process small sized products.

Mastering mold manufacturing technology helps Thaco Industries be proactive in production and business, completing the value chain according to the All-in-one model (providing a complete solution from product research and development to processing, manufacturing, production, assembly, operation transfer and maintenance), contributing to increasing competitiveness when participating in the global supply chain.

Leverage for modern manufacturing and supply chain integration

At this time, limitations in technological capacity and lack of high-quality human resources are some of the difficulties that mechanical mold enterprises are currently facing. Meanwhile, the number of engineers graduating from school each year is still small and cannot work without retraining.

|

| The Ministry of Industry and Trade will also continue to improve policies to promote the development of the supporting industry in general and the mold sector in particular. Photo: HT |

According to the Department of Industry (Ministry of Industry and Trade), in order to improve manufacturing capacity and master mold technology for businesses, from 2020 to present, the Ministry of Industry and Trade has cooperated with Samsung Vietnam to implement many practical and effective programs, contributing to improving the capacity of the supporting industry in Vietnam.

In 2024, the Industrial Development Support Center (IDC Center) - Department of Industry also coordinated with Samsung Electronics Vietnam Co., Ltd. to organize a training course in Korea within the framework of the Project "Supporting training to improve the quality of design engineers, manufacturing and mold production in the supporting industry".

This training program has equipped students with in-depth knowledge of mold design and manufacturing, combined with practical production practice sessions at advanced facilities in Korea. In addition, students also participate in business tours (Benchmarking) in Korea, thereby learning about modern technologies and production processes, while enhancing creativity and innovation in work.

With the combination of theory and practice, the students have successfully completed the training course, not only improving their professional qualifications but also equipping themselves with problem-solving skills, creativity and innovation in mold design and manufacturing.

The training programs have gradually built a team of experts with the capacity to advise and retrain domestic mold enterprises, helping enterprises improve their competitiveness in the global supply chain and contributing to the sustainable development of the supporting industry in particular and the manufacturing industry in general in the context of globalization and the 4.0 industrial revolution.

In 2025, the Department of Industry will continue to promote activities to support consulting and technical innovation for businesses in the electronics and automobile sectors; train human resources and exchange technology through the Vietnam - Korea Technology Consulting and Solution Center (VITASK). At the same time, exchange and discuss the expansion of the project into phase 2 (from 2024 - 2028).

In the coming time, the Ministry of Industry and Trade will continue to improve policies to promote the development of the supporting industry in general and the mold sector in particular; have incentive programs and mechanisms to encourage enterprises to apply modern science and technology in mold production to create a solid foundation for domestic and export industries. |

Source: https://congthuong.vn/cong-nghe-khuon-mau-don-bay-phat-trien-cong-nghiep-ho-tro-391683.html

Comment (0)