Spinning flax fibers into large skeins for weaving flax. (Photo: Nam Thai/VNA)

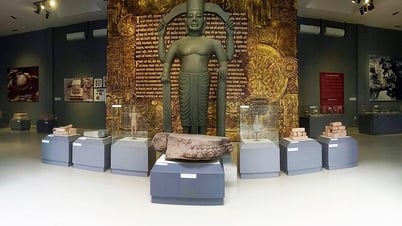

Ha Giang - the rocky plateau - not only attracts domestic and international tourists by its vast fields of buckwheat flowers, winding mountain passes and charming terraced fields in the ripe rice season, sparkling in the pouring water season, and immense mountain ranges, but also by its rich traditional cultural features of ethnic minorities.

For the Mong people in Lung Tam commune, Quan Ba district, Ha Giang, linen is a cultural symbol. People here still maintain the traditional linen weaving profession using natural materials and manual processes.

The linen weaving profession of the Mong people has a very great significance for the traditional culture of the nation, a vivid proof of the diligence and hard work of the people who have overcome all the difficulties and harshness of nature to build an increasingly beautiful life.

Since 2001, Lung Tam Linen Weaving Cooperative has not only been established as a place to preserve and develop unique cultural features, helping to improve the income of local people, but also become a destination that many Western tourists seek out when traveling to Ha Giang. Coming here, in addition to learning about the linen weaving process, visitors also have the opportunity to directly experience the steps to create a piece of fabric.

In Lung Tam, visitors can admire the handmade linen products created by Mong women. In addition to shirts and skirts, linen is now also present in many products such as tablecloths, handbags, and wallets.

Tourists visit and experience the linen weaving process. (Photo: Nam Thai/VNA)

Ms. Vang Thi Mai, Head of Lung Tam Linen Cooperative, shared that linen plays an important role in the culture and spirituality of the Mong people. Knowing how to weave linen is considered a criterion to evaluate the talent, dexterity and diligence of a Mong woman. When going to her husband's house, the daughter must wear linen clothes to receive the blessing of her husband's ancestors.

According to local elders, when Mong girls reach adulthood, their families give them their own land to grow flax. Before they get married, they must know how to weave linen. When they move to their husband’s house, their mother-in-law will give their daughter-in-law a set of linen. The new bride gives her mother-in-law the linen set that she woven and sewed.

Weaving linen also demonstrates dexterity and diligence and has become one of the criteria for evaluating a woman’s talent and virtue. The Mong believe that linen helps connect descendants with their ancestors.

The main raw material for weaving flax is flax. Flax plants are harvested after about two months of planting. If harvested early, the flax fibers will be tough. If harvested late, it will be difficult to peel the bark. When peeling the flax bark, it must be in a place away from sunlight and wind to avoid the flax bark sticking to the tree trunk.

After separation, the flax hull is pounded in a mortar until it curls, then the fibers are joined by rolling the fibers directly onto a hand or wooden stick, connecting tip to tip, root to root, ensuring that the joints are of equal width.

After connecting, soak the flax fibers in cold water for 15-20 minutes and then put them on the spinning frame.

According to Ms. Vang Thi Mai, a finished linen product must go through 41 stages, from growing flax, harvesting, separating fibers, pounding fibers, spinning fibers, cooking fibers, building weaving frames, etc.

"To have a beautiful piece of fabric, the craftsman must love the job, be patient and skillful," said Ms. Mai. The flax fibers must be even right from the separation step, so that the woven fabric will be durable and beautiful. After separation, the flax fibers are pounded to soften, then joined together to create long fibers. The Mong people also invented a spinning tool that combines the hands and feet (photo) to spin 4 flax fibers at the same time.

The yarn is then put into a spinning frame to be unwound and bundled into bundles, then boiled with wood ash, soaked and washed. This process is repeated until the linen is white, then dried and put into a weaving frame. When the yarn is put into the frame, depending on the width of the fabric, the worker counts the exact number of yarns.

The Mong people still weave cloth by hand using looms. The weaving process is usually undertaken by experienced older artisans who can handle broken or damaged threads.

The finished woven fabric is placed between a stone slab and a wooden pillar. The worker stands on the stone slab and rolls it back and forth until the entire surface of the fabric is flattened, soft and smooth, then soaks it in wood ash for a week to whiten it and then dries it. A beautiful linen fabric must have even, white and smooth threads. Linen is durable and absorbs moisture, so it feels cool when worn.

In addition to weaving, Mong women in Lung Tam also have the technique of beeswax painting and indigo dyeing. This is the most difficult step because it depends on the weather, and can only be done when the weather turns to summer.

Mong ethnic women paint beeswax on linen. (Photo: Nam Thai/VNA)

The craftsman paints traditional Mong patterns on white fabric with heated beeswax. When the fabric is dyed, the impermeable beeswax lines will highlight the patterns on the fabric. Meanwhile, the indigo dyeing technique produces colorful fabrics. The dyes used are also completely natural.

The work of painting on fabric seems simple, but is actually very elaborate. To paint beeswax on linen, the artisan must sit for many hours, many days by the wax stove, meticulously using a “pen” made from a bamboo stick about 10cm long, with a thin copper blade at the tip.

When drawing, the artist must dip the tip of the pen into a pan of beeswax that is steaming hot over a charcoal stove, then skillfully draw straight lines on the fabric. When drawing, he must adjust the amount of wax to flow evenly, without streaks, until the "wax ink" is gone before continuing with the next stroke.

Nowadays, when coming to Ha Giang, tourists will easily see Mong women always carrying bundles of flax to spin and join threads anywhere, when going to the market or going to the fields.

Mr. Okabe Takashi, a tourist from Japan, expressed that when he came to Lung Tam and witnessed people doing each step, he found this work extremely meticulous, elaborate, and laborious.

He thinks that if these handicrafts were made in Japan, the price would probably be too high and difficult to buy. He hopes that Vietnam will continue to maintain and develop craft villages like this.

Sharing the same view, Ms. Nguyen Thi Bich Ngoc, a tourist from Hanoi, after visiting the linen weaving process of the people in Lung Tam commune, expressed that when she came to the craft village and was introduced and guided through each step, Ms. Ngoc was surprised, because if she just looked at it, she would not be able to imagine that it would take so many steps to create a piece of linen fabric.

Tourists visit and shop for products woven from linen. (Photo: Nam Thai/VNA)

Buying flax products as gifts, Ms. Ngoc expressed her wish that flax products will be sold in more places, both to promote a traditional local product and to bring more income to the local people.

Up to now, after more than 10 years of establishment (from 2001 to present), Lung Tam Flax Cooperative has grown from more than 10 initial members to over 130 members with 9 production groups. According to Ms. Vang Thi Mai, the average income of members is from 3-4 million VND/month. Highly skilled members have income ranging from 6-7 million VND/month.

Along with labor and production to generate income from selling products and welcoming tourists, the Cooperative has been teaching the profession to the young generation. In particular, at the Cooperative's headquarters, 25 children from disadvantaged and orphaned families are being trained in the profession to help them have another job in hand and preserve the culture and beauty of the linen weaving craft of the Mong people, Ms. Vang Thi Mai added.

Vice Chairman of the People's Committee of Lung Tam Commune, Quan Ba District, Vuong Dinh Ba, assessed that Lung Tam Flax Cooperative operates quite effectively and stably, creating jobs for local people, helping them earn income from traditional occupations, thereby improving their lives.

Currently, Lung Tam Linen Cooperative produces many types of products such as shirts, dresses, scarves, handbags, wallets, duvet covers, tablecloths, etc. In addition, artisans also create paintings to hang in hotels and restaurants, and make small, pretty souvenirs.

Products woven from linen are considered good for health because of their ventilation, high moisture absorption, and resistance to mold.

Source link

Comment (0)