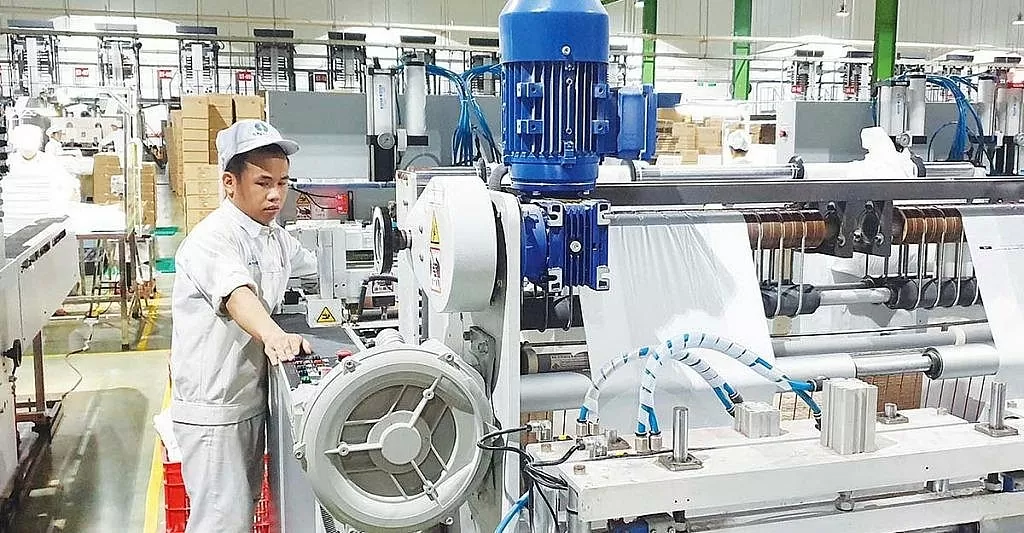

View from the plastics and chemicals industry

According to the Department of Industry ( Ministry of Industry and Trade ), although the plastic industry is one of the industries with high growth, it is still only known as a technical economic sector of plastic processing. In particular, the plastic industry is still not self-sufficient in input materials.

|

Although domestic raw material sources are increasingly diverse, many industrial enterprises still have to import. Photo: TT |

Specifically, 70% of raw materials and input materials must be imported because the current domestic supply can only meet about 1 million tons. In particular, there is a lack of supply of recycled plastic materials and the supporting industry for the plastic industry is underdeveloped. Enterprises are not self-sufficient in input materials; the cost of raw materials accounts for the highest proportion in the industry's cost structure. This situation leads to plastic enterprises having to maintain large inventories of raw materials to ensure uninterrupted production and business activities.

According to a report by the Vietnam Plastics Association (VPA), in 2024, the Vietnamese plastics industry will import 8.5 million tons of virgin and recycled plastic pellets, and the amount of imported scrap plastic as raw materials for production will reach an average of 0.5 million tons/year. PP plastic products will have an import turnover of 1.5 billion USD, while PE plastic products will have an import turnover of 2 billion USD.

Notably, in the first quarter of 2025, the country imported 2.28 million tons of raw plastic materials (also known as plastic or polymer) with a value of 3.02 billion USD, an increase of 25.2% in volume and 20.8% in value compared to the same period in 2024.

VPA said that Vietnam's plastic industry is 70% dependent on imported raw materials from countries around the world such as Saudi Arabia, Korea, Thailand, Japan, the US, China, Malaysia, Singapore, etc. Of which, China continues to be the largest market supplying plastic raw materials to Vietnam, accounting for 29.2% of the market share.

Another limitation mentioned by the Ministry of Industry and Trade is that small and medium-sized enterprises (accounting for more than 90% of the total 2,000 plastic enterprises) often pay little attention to investing in modern technology and machinery, so Vietnamese plastic products are mostly in the low-end segment. Only a few large-scale enterprises are willing to invest in depth and have products that meet the increasing needs and tastes of consumers, making the competitiveness of Vietnamese plastic products in the market not high, especially household plastic products.

Not only the plastics industry, but also the chemical industry still has to import industrial salt mainly because the output and quality of domestically produced salt have not met the needs of industries, especially the chemical industry. Industrial salt requires high purity, with a sodium chloride (NaCl) content of 98% or more, and low levels of impurities. Meanwhile, traditional salt production in Vietnam is mainly manual, with low productivity, and the quality has not met the requirements of industries.

A representative of a chemical manufacturing company said that domestic salt is mainly table salt, while businesses import industrial salt refined from raw salt to be the main raw material for producing basic chemicals such as caustic soda, soda ash, etc. to serve the medical and chemical industries. The domestic salt industry produces manually and of low quality, so it cannot supply enough industrial salt for chemical businesses.

Proactive response

In fact, the story of the lack of raw materials for key manufacturing industries shows that self-sufficiency in domestic production materials still has many challenges ahead.

Regarding the plastics industry, Mr. Ho Duc Lam - Chairman of VPA said that plastics is a key industry that is assessed to have a lot of potential and many opportunities for domestic enterprises. VPA proposed that the authorities should create opportunities and increase investment capacity in companies and projects producing raw materials for the plastics industry. Furthermore, plastics enterprises should also focus on finding and developing domestic raw material sources to avoid risks affecting import and export activities. "Domestic plastics enterprises need to gradually expand factories, prepare raw material sources, promote products with high added value... This is considered one of the solutions for plastics enterprises to affirm their advantages" - Chairman of VPA proposed the solution.

Regarding industrial salt products, according to the Department of Chemicals (Ministry of Industry and Trade), it is necessary to have a policy to build high-quality raw material areas, while creating conditions for businesses to invest in technology to produce and solve the crisis of shortage of industrial salt and high-quality salt in Vietnam.

On the side of the Department of Industry, it is said that production units need to closely follow market developments and demand, promote domestic production, and replace import demand in the context of high world price levels.

The Ministry of Industry and Trade also directed the Trade Offices to actively search for, provide and regularly update the list of distributors and manufacturers exporting raw materials and accessories for raw materials, fuels and materials serving the production of the chemical, wood, iron and steel industries...

In the long term, the Ministry of Industry and Trade also orients that there needs to be long-term solutions to develop a number of basic materials industries, overcoming dependence on imported input materials. In particular, focusing on supporting the improvement of business capacity through support solutions on credit, human resources, innovation and market development as well as tax and land incentives.

In addition to supporting market information and connecting supply and demand, the Ministry of Industry and Trade will also strengthen the expansion of new markets to help businesses avoid dependence on one market in terms of import and export, effectively taking advantage of the advantages and commitments in the FTAs that Vietnam has participated in.

| In the long term, the industry needs to increase its autonomy in raw materials and reduce its dependence on imports to enhance the value and competitiveness of products in the global value chain. |

Source: https://congthuong.vn/doanh-nghiep-cong-nghiep-lo-i-gia-i-nao-cho-bai-toan-nguyen-lieu-389034.html

Comment (0)