Not only providing clean glasses of TH true MILK fresh milk from the world record farm cluster, for many years, TH Group has also participated in developing green and sustainable Vietnamese agriculture.

More than 14 years ago, TH Group began investing in Nghia Dan district ( Nghe An ) with a high-tech concentrated dairy farming and milk processing project with a total investment of 1.2 billion USD.

Up to now, on Nghia Dan land, a closed chain of agricultural production, dairy farming and high-tech milk processing has been formed "From green pastures to clean glasses of milk".

The project has a herd of nearly 70,000 cows, a modern milk factory with a construction area of 5.2 hectares, and a processing capacity of more than 1 million liters of milk per day. In 2020, TH set a record for the world's largest closed-loop high-tech concentrated farm cluster, and still holds this record to this day.

The TH milk project is currently being expanded to many provinces and cities across the country, of which farms in Phu Yen and Thanh Hoa have come into operation.

Traveling along Ho Chi Minh road today, visitors from near and far can see the changes of the Phu Quy red basalt land with vast Mombasa grasslands, covering an area of up to 2,230 hectares.

Or the vast corn and sunflower growing areas; large-scale, impressive factories and farms with modern, high-tech machinery and equipment in operation.

In the fields that stretch as far as the eye can see, TH uses modern machinery systems for every step of the farming process from tilling the soil, sowing seeds to harvesting. Among them, there are large harvesters that have the productivity of hundreds of manual workers.

Notably, TH also guides and cooperates with farmers to grow corn and grass according to clean farming standards, guarantees product consumption, and annually purchases raw materials with a total value of over 100 billion VND from thousands of farmers in the project area.

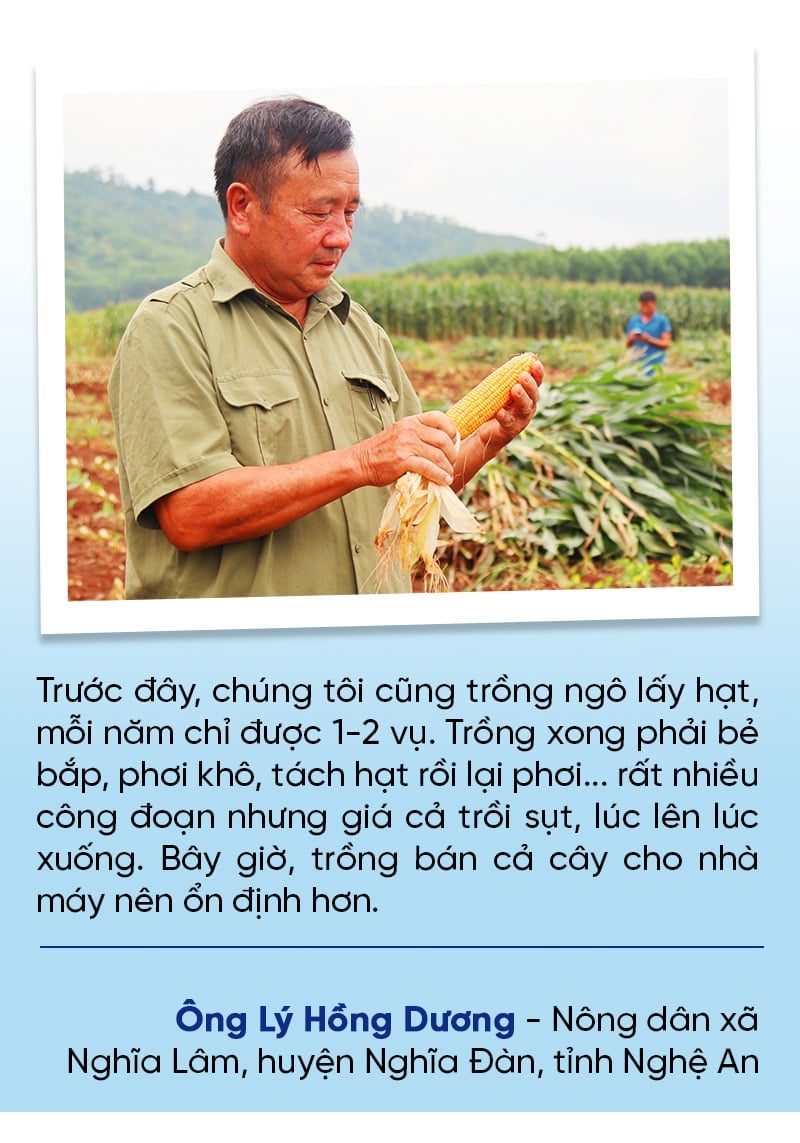

Standing next to a vast corn field in the harvest season, Mr. Ly Hong Duong - a farmer in Nghia Lam commune, Nghia Dan district, Nghe An province - said that in the past, his family grew rubber but the storms knocked down many of them, so he boldly switched to growing biomass corn to sell to the TH true MILK dairy farm.

Mr. Duong's family has 6 hectares of land, of which 5 hectares have been used to grow biomass corn.

“In the past, we also grew corn for grain, and only had 1-2 crops per year. After planting, we had to pick the corn, dry it, separate the kernels, and dry it again… there were many steps, but the price fluctuated, sometimes up and sometimes down.

Now, growing and selling the whole tree to the factory is more stable," said Mr. Duong.

Nghia Dan District Party Secretary Pham Chi Kien shared that after more than a decade since TH's factories were invested in, built and put into operation, Nghia Dan district has "changed its skin".

TH's projects have contributed to creating a major shift in the economic and labor structure, creating a breakthrough in the economic development of Nghia Dan district.

“With the cooperation in building large-scale model fields, providing input materials for TH farms and factories to serve dairy farming or sugar production, farmers have stable jobs and increasingly high incomes, and their material and spiritual lives are constantly improving,” Mr. Kien said, citing that from a difficult land with a poverty rate of up to 23%, the number of poor households in Nghia Dan district is now only 6.4%.

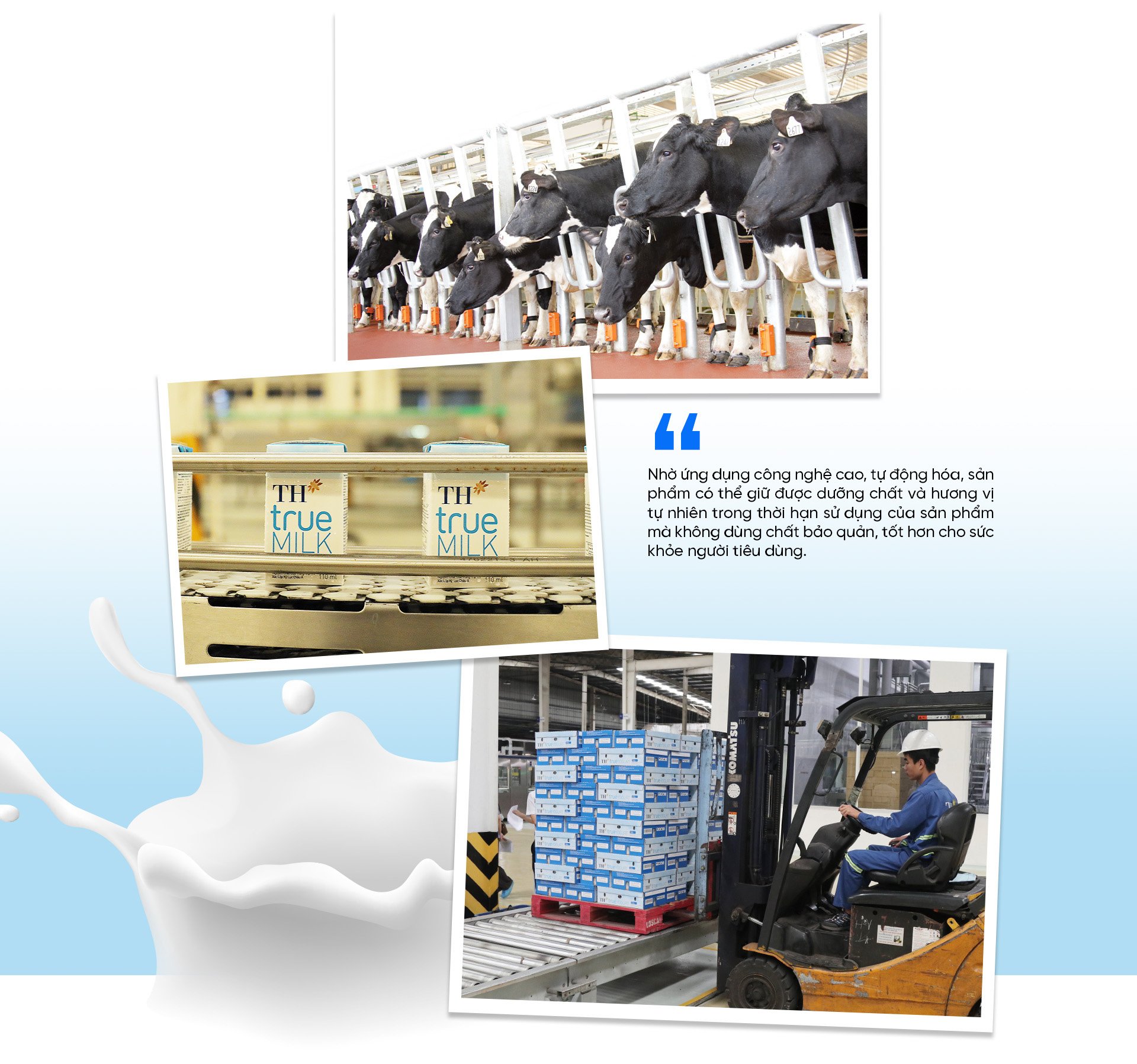

With the motto "Clean fresh milk is the only way", TH has applied a closed production process "From green pastures to clean glasses of milk", applying modern technology, automation, 4.0 technology in agricultural production and deep processing, to produce TH true MILK clean fresh milk that meets international quality standards from the "land" of Vietnam.

Mr. Nguyen Tien Dung - Production Director of TH Fresh Milk Factory - said that during the entire process from when the milk is milked until it reaches the factory, the raw fresh milk is not exposed to air at all.

This is an important factor in controlling milk quality, a big difference between industrial farming and household dairy farming.

Thanks to the application of high technology and automation, the product can retain nutrients and natural flavors during the product's shelf life without using preservatives, which is better for the consumer's health.

TH’s concentrated dairy farm is located in the lower reaches of the Sao River on the Phu Quy plateau. The gentle river becomes a natural source of birth, nourishment and new vitality for the Western Nghe An region.

In 2011, the group's first domestic water treatment plant was completed and put into operation, helping TH become self-sufficient in water resources for production.

Currently, the group owns 3 domestic water plants with a total capacity of 14,500m3 /day and night. The plants use Amiad - Israel technology - the world's leading modern domestic water treatment technology today, 100% automatic.

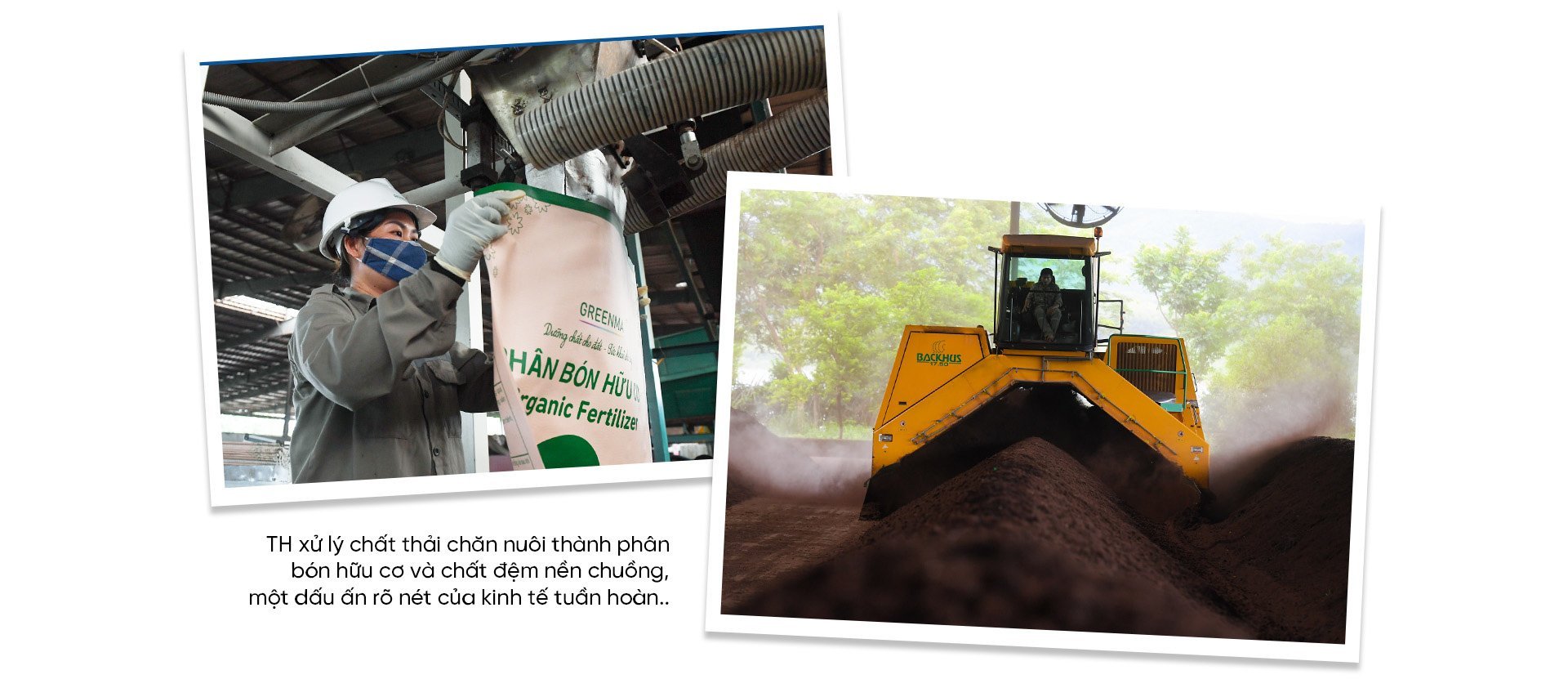

Mr. Pham Vinh Son - General Director of Green Fertilizer Technology Joint Stock Company, an important link in the green, circular and environmental protection production chain of TH Group - said: "Implementing the circular economy, at TH farms, all waste products from one stage are the input of another stage.

By-products from the livestock and production process are considered renewable resources rather than waste, thereby reducing resource exploitation, emissions, environmental pollution, and protecting nature.

Waste from the livestock process after being treated to meet standards becomes biological buffer for the farm and high quality natural organic fertilizer returned to serve the raw material fields as well as supply to the market.

Thanks to this process, the group has reduced methane emissions by 60-70% compared to conventional measures.

The dairy farm in Nghe An has invested in a solar panel system and officially connected to the national grid since the end of 2020. This project has brought many benefits in terms of economic value, environmental protection, and contributed to effectively reducing the load on the national grid.

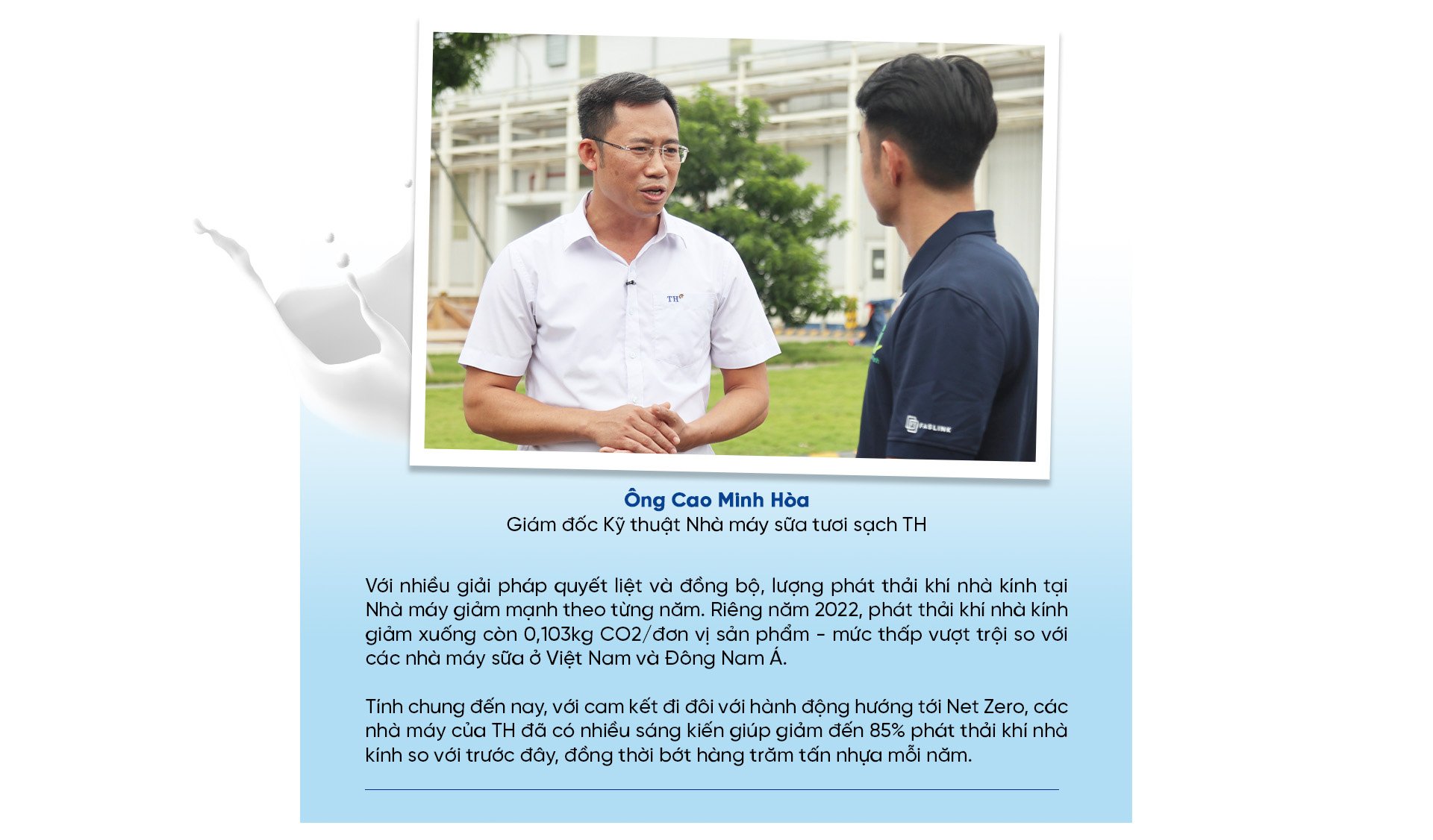

Mr. Cao Minh Hoa – Technical Director of TH Fresh Milk Factory – said that each year the solar panel system produces 7 million kWh. According to calculations, the energy converted from light energy to electricity by the solar panel system at the farm helps reduce emissions equivalent to about 5,000 tons of CO2/year.

If calculating the cost according to the purchased electricity price, with the current self-produced electricity output, this unit is saving more than 10 billion VND each year.

In particular, according to Mr. Hoa, the solar panel system with about 1,500 panels installed on each farm roof, in addition to absorbing solar energy, also has the effect of reducing heat radiation, helping to regulate the air inside the barn, contributing to saving electricity.

“The survey shows that the temperature of barns with solar panels installed on the roof is always 4-5 degrees Celsius lower than those without. This helps reduce the heat in the barn space, helping the cows have a cooler, more comfortable living environment, reducing stress and fatigue due to hot weather, thereby producing more milk.

This is also one of the animal welfare commitments that the group makes,” Mr. Hoa shared.

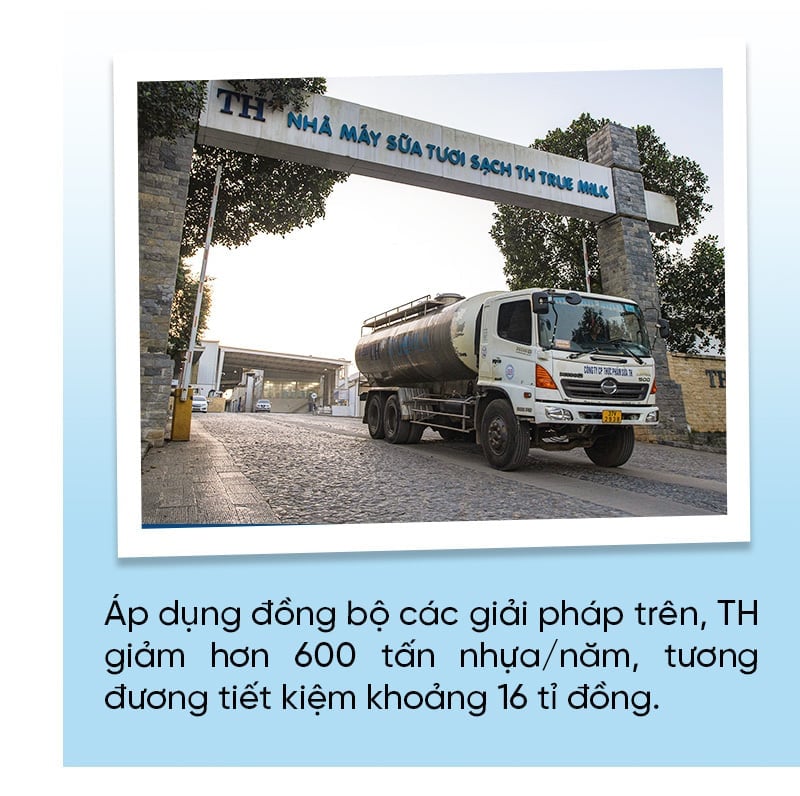

With the goal of sustainable development, the group has also made efforts to reduce plastic in the production process such as: replacing plastic bags and disposable plastic yogurt spoons with bags and spoons made of environmentally friendly biological materials; reducing the number of yogurt spoons given away with TH true YOGURT product boxes; completely removing shrink wrap on purified water bottle caps; reducing the weight of plastic bottles; reducing the thickness of bottle labels...

By synchronously applying the above solutions, TH reduces more than 600 tons of plastic/year, equivalent to saving about 16 billion VND.

In addition, TH has implemented milk carton collection programs since 2022. After collection, milk cartons will be transferred to professional recycling units and "reborn" into new products and items such as roofing panels, school desks and chairs, etc.

![[Photo] General Secretary To Lam works with the Standing Committees of the 14th Party Congress Subcommittees](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F09%2F1765253019536_a1-bnd-0983-4829-jpg.webp&w=3840&q=75)

![[Photo] Urgently help people soon have a place to live and stabilize their lives](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F09%2F1765248230297_c-jpg.webp&w=3840&q=75)

Comment (0)