What is a large format laser cutting machine?

Large format laser cutting machine

Large format laser cutting machine is a type of laser cutting machine with a large working area, usually from 3x6m or more, and a laser source with a power of 6kw or more. The large working area allows the machine to cut large metal plates. The higher the laser power, the stronger the metal cutting ability, allowing the cutting of thicker, larger metal plates with higher precision.

Large format laser cutting machines are widely used in heavy industries, especially steel structures, shipbuilding, mechanical engineering, automobiles, aerospace, etc. In general, large format laser cutting machines meet the needs of large-scale manufacturing industries.

Benefits of using large format laser cutting machines for the steel structure industry

The steel structure industry is one of the main drivers of economic growth in many countries. It is responsible for the construction of buildings, bridges and other infrastructure. To meet the growing demand for steel structures, manufacturers need to invest in high-tech equipment.

One of the important equipment for the steel structure industry is the large format laser cutting machine. The machine is used to cut thick metal plates with high precision and speed, which is essential for the construction of large projects.

Large format laser cutters are an advanced type of laser cutting machine. They offer a number of benefits over traditional laser cutters, including:

- Increased productivity: Large format laser cutting machines can cut larger and thicker metal plates, which can significantly improve productivity. High pressure compressed air can be used to cut iron at high speed.

- Improved Accuracy: These machines can cut metal sheets with greater precision than cnc plasma cutting, which is essential for building complex structures.

- Reduced costs: More efficient sheet metal cutting machines help save costs.

- Enhanced flexibility: The machine can cut large-sized and thick workpieces, providing more options in the production process.

Son Vu CNC large format laser cutting machine

Some notes for large format laser cutting machines:

- The machine table for placing workpieces must be lined with fireproof bricks to protect the table from damage by high-power laser beams and molten metal during the cutting process.

- It is necessary to equip the exhaust fan and dust filter system to protect the equipment on the machine and ensure the health of the operator.

- The machine must be equipped with electronic fences on the front and back of the X-axis to ensure safety. When there is an obstacle in the protection zone, the machine will automatically stop.

- Add beveling function: This feature is very useful for beveling metal plates at a 45 degree angle to help increase the adhesion of the weld, making the weld stronger and more durable. This feature is an optional part when needed.

Workpiece table with fireproof brick lining

Challenges in manufacturing large format laser cutting machines

Large format laser cutting machines are complex industrial machines that require high technology and engineering in production. Below are some of the challenges and difficulties in producing this type of machine.

1. The two vertical shafts of the machine shall be made of high-strength materials, resistant to high temperatures and pressures, and shall be properly stress-relieved. The machine feet shall be constructed to be easy to install, easy to adjust, and to minimize the effect of floor subsidence on the accuracy of the machine.

2. High installation requirements: If the two vertical axes of the machine are not installed in parallel properly and the tolerance exceeds 2 μm, the mechanical parts (slideway and motor) will be easily damaged. Without extensive and deep installation experience, it is difficult to achieve long-term stable operation.

3. Poor synchronous operation of the cross beam can lead to bending or breaking of the output shaft of the reducer.

4. High requirements for the mounting plate of the reducer: Special techniques are required to enhance its hardness and toughness, ensuring that it will not deform during long-term operation.

5. If the Z axis is not designed and manufactured well, vibration may occur during cutting, resulting in small holes not being round and the cutting line being jagged.

These are not easy tasks, because in reality there are not many manufacturers who can make high quality large format laser cutting machines, especially for low-cost machines.

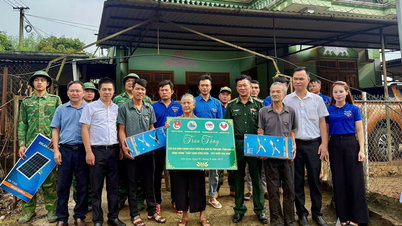

Large format laser cutting machine of Son Vu CNC at Dai Dung Factory

Contact Son Vu CNC today to learn more about how Son Vu CNC can help you improve productivity and profitability./.

SON VU TECHNOLOGY JOINT STOCK COMPANY Showroom: B11/10 KP2, Tan Tuc town, Binh Chanh district, Ho Chi Minh City Phone: 028 2262 9898 – Mobile: 0908182124 Email: Sales@sonvucnc.com |

DC

Source

Comment (0)