Ho Chi Minh City is in a blazing heat in the last days of the year of the Cat. At 7am, Nam Ky Khoi Nghia Street, an extension of Nguyen Van Troi Street from the city centre to the gateway to Tan Son Nhat Airport, is already crowded and bustling. People are going to work, shopping for Tet, and people are rushing home early to avoid the peak season... making the road stuffy from early morning.

The passenger terminal project has a scale of 1 basement and 4 floors above ground, with a total construction floor area of 112,500 m2, and has completed more than 50% of the rough construction after only 3 months of construction.

Inside the construction site of Tan Son Nhat Airport's T3 terminal, the sounds of hammers, drills, and cranes have been rumbling since 6 a.m. More than 16 hectares of land were handed over by the Ministry of National Defense to the Vietnam Airports Corporation (ACV) to build the key project, and have been covered with iron and steel. Of which, the terminal structure with 1 basement and 4 upper floors extending to the parking area and non-aviation center services has gradually taken shape.

Nearly 50 cranes along with hundreds of equipment, machines and many engineers and workers are working hard under the scorching sun of the South at the end of the year, making the atmosphere even more urgent.

Contractors have mobilized 1,400 workers, 16 tower cranes and over 350 vehicles to participate in the project construction.

Mr. Le Khac Hong, Head of the T3 Passenger Terminal Construction Project Management Board (T3 Passenger Terminal Project Management Board) said that in the context of an increasingly scarce construction labor market, the consortium of 5 contractors had to implement many new policies to mobilize more than 1,400 workers and engineers to Tan Son Nhat to serve the construction of this project.

To ensure the completion of the entire station within 20 months as planned with the Prime Minister , the project must be carried out without any breaks on all holidays, New Year, and weekends. Workers are mobilized on a fixed schedule, divided into rotating shifts, ensuring that in all cases at least 70% of the workforce is always kept on site.

The area is narrow, workers have to take advantage of every small space to gather and process materials.

Due to the limited area, it was very difficult to organize the construction site, crane installation, service roads, material yards, and worker camps, so the contractors had to coordinate and divide the area into small areas for rolling construction. Workers and engineers worked continuously in 2 shifts a day from 6am to 10pm, except for the work of transporting concrete, materials, and dumping waste, which operated overnight.

Failure to build internal roads that meet demand also greatly affects the project's construction capacity.

To minimize the risk of delays, instead of controlling by target, the Management Board of AT3 has switched to controlling by process. Specifically, contractors are required to register a construction plan within 15 days. After 15 days of progress review, any unit that has not completed the work must both work on the output of the next 15 days and have a plan to compensate for the progress of the previous 15 days. Any contractor who is behind schedule 3 times will be "eliminated" directly.

Thousands of workers have to work continuously in 2 shifts from 6am to 10pm to "race" to meet the progress.

Thanks to determination and high discipline, the project has achieved many very good progress milestones. Specifically, the package "Construction of demolition, ground, pile foundation, basement floor" started on December 24, 2022 and was completed on November 15, 2023. The package "Construction and installation of equipment for passenger terminal T3" started on August 31, 2023, the contract officially took effect on October 15, 2023, and after more than 3 months, the overall progress has been about 50% of the rough construction. The units are striving to complete the floor, basement cover, SOG floor, the entire 2nd floor adjacent to the aircraft parking lot by February 5 (before Tet Giap Thin) and complete all floors by May 15, start assembling the iron truss structure, roof.

Concrete, material and waste transportation must operate overnight.

Contractors must comply with "15-day progress control" and have solutions to compensate for delays.

QLDAT3 Board, contractors and workers also have to take turns and flexibly mobilize to maintain the pace at the "hot" construction site during holidays and Tet.

The construction of the multi-storey parking garage combined with non-aviation services has also reached 50% of the rough construction volume. According to the plan, all walls will be completed by February 5, the B1 tunnel cover will be closed, and the rough construction will be completed by August 10. From May 29 to May 20, 2024, the contractor will install elevator and escalator equipment, security screening, baggage conveyors, passenger bridges, etc. to "finalize" the finishing work to put the terminal into use.

The high-rise parking lot combined with non-aviation services is a complex of 2 basements, 4 above-ground floors and a 3-storey motorbike parking lot connected by a bridge corridor, with a total construction floor area of 130,000 m2.

"Up to now, the construction of the main part of the project is under control according to plan. If this momentum is maintained, the project is guaranteed to finish on schedule. Terminal T3 is currently the largest passenger terminal in the country. With the task of construction in 20 months in a very challenging context. However, both the Corporation, the Management Board and the contractor are determined to focus all resources to bring the project close to schedule" - representative of BQLDAT3 shared.

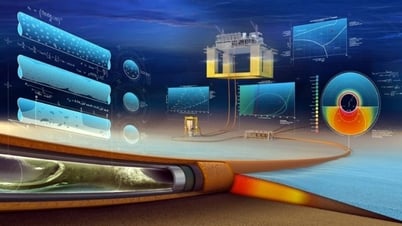

Perspective of T3 terminal expected to be put into operation in the second quarter of 2025

Mr. Le Khac Hong:

T3 has the most modern technology applied for the first time in Vietnam.

Terminal T3 will apply the most modern technologies never seen before at any passenger terminal in Vietnam. For example, the entire check-in system will use AI technology. In addition to about 115 traditional check-in counters, ACV will deploy at T3 42 more check-in kiosks that can check in for all airlines, without having to classify each airline as it is now. In addition, there are 20 check-in counters that apply "bag drop" technology, allowing passengers to weigh and check in their luggage without having to go to a counter with airline staff. With a capacity of 20 million passengers, Terminal T3 will also have an automatic baggage sorting system, greatly reducing check-in time for passengers.

Source link

Comment (0)