Technical innovation from dragon fruit cultivation

Mr. Vo Van Be (Nha Viec Hamlet, An Luc Long Commune, Chau Thanh District, Long An Province) has more than 25 years of experience growing dragon fruit. He is one of the first dragon fruit growers in the commune. In the beginning, for every 1,000m2 of land, he only planted about 70-80 dragon fruit trees. After researching and studying, Mr. Be increased the planting density, thereby increasing productivity and income. Currently, Mr. Be's dragon fruit field has an area of nearly 9,000m2 .

After several years of growing, Mr. Be applied the dragon fruit fumigation technique. The circuit breaker is placed outside the field, and turning it on and off takes time and effort. When it rains, this is even more dangerous, and electrical accidents can easily occur. From that difficulty, he researched and created a remote control system. Each circuit breaker has a sensor system connected to a phone sim. Users only need to hold their phone to turn it on or off, even if the distance is hundreds of kilometers. The system also has a timer mode to help farmers save electricity.

Nearly 20 years ago, people mainly used cell phones with numeric keypads, without much software like today's touch phones. Mr. Be's creation of the remote control system created a buzz in and outside the locality. Currently, his initiative is still useful and widely applied, helping many farmers grow dragon fruit. In addition, he also changed the light bulb from 75W to 9W to save electricity without affecting the quality of the fruit.

Following the State's recommendation, Mr. Be switched to a dragon fruit irrigation system using automatic sprinklers for more than 3 years. Previously, because the field was far from the water source, watering the dragon fruit was quite difficult. Mr. Be had to pump water from the water source to the pond and then from the pond to the field, which was very costly. To solve the problem, he boldly invested in a 400m long pipeline from the water source to the field, combined with automatic sprinklers, which helped save a lot of effort and money.

Mr. Be's field is far from the main road. Realizing that transporting goods by motorbike is potentially unsafe and inefficient, he invented a cart that can transport 1 ton of dragon fruit at a time. In addition, he also created a winch system to transport baskets of dragon fruit from the ground to the vehicle.

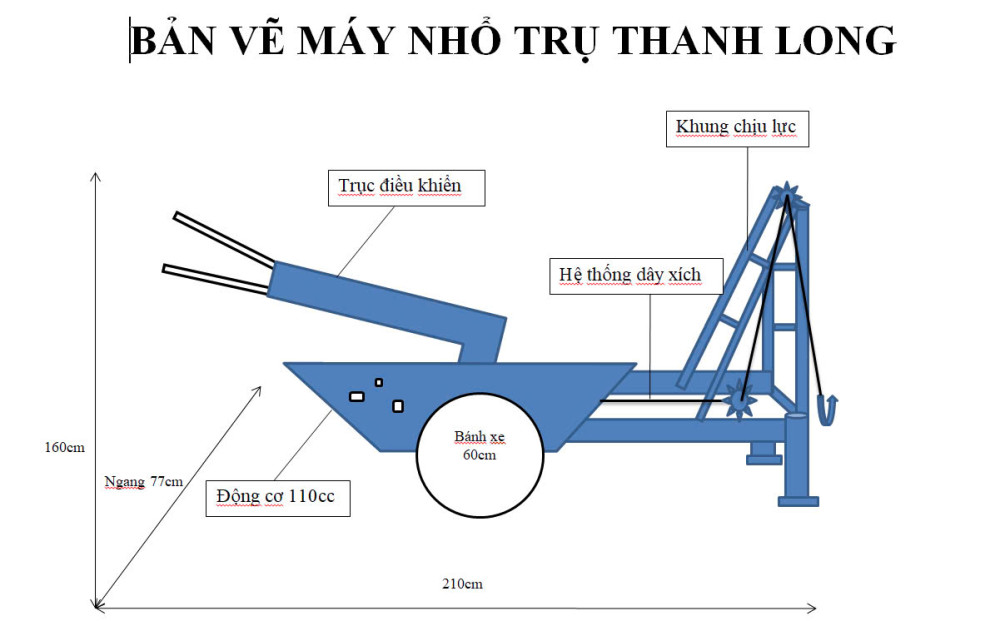

Dragon fruit is planted with concrete pillars, some of which are longer than 2m, buried deep in the ground. Each time it is pulled up, it requires many people and a lot of strength, but it is not always possible to find workers to pull it up. Faced with such difficulties, in 2023, Mr. Be invented a dragon fruit pillar pulling machine. This solution was certified by the Provincial Farmers' Association for the 8th Technical Innovation of Farmers.

Mr. Be researched on social networks, then bought tools and equipment to make at home. The machine consists of a 110cc Honda engine, a hand plow, iron and some other accessories. With this machine, Mr. Be can work alone, with a productivity of 20 pillars/hour, saving time and effort many times over compared to manual work.

According to the Chairman of the Farmers' Association of An Luc Long Commune - Ngo Nguyen Duy Linh, this is the first dragon fruit pole pulling machine in the locality, gradually replacing human labor in growing dragon fruit as well as other agricultural activities.

Mr. Be shared: "I realize that agricultural production today needs to be mechanized, applying new science and technology to keep up with the times, producing good agricultural products at economical costs." In 2024, Mr. Be was awarded a Certificate of Merit by the Chairman of the Provincial People's Committee for his outstanding achievements in building a commune that meets the model new rural standards in organizing production and developing the rural economy in 2023.

Farmers with a passion for innovation

Born into a farming family, since childhood, Le Van Lung (born in 1976, residing in Cau Lon hamlet, My Lac commune, Thu Thua district) has had a passion for creating machinery for agricultural production.

Although he did not have formal education or a formal degree, with his skillful hands and endless creativity, he successfully researched and improved the 3-in-1 seeding machine (seeding machine, clustering - leveling the field - digging drainage ditches). His invention not only solved the difficulties in farming but also contributed to improving production efficiency.

Faced with the current reality of agricultural production, when labor is increasingly scarce and labor costs are increasing, Mr. Lung thought and found ways to reduce labor, lower input costs to improve economic efficiency. From that idea, he researched and improved the 3-in-1 seeding machine with high applicability, helping to reduce labor and increase productivity in agricultural production.

The machine operates simply, compactly and highly efficiently, such as using the traction of the plow and the transplanter to pull the "3-in-1 seed seeder". The machine is designed with a seed container with a length of 2.5m, a rotating shaft attached to 2 wheels so that when the tractor operates, the 2 wheels move, causing the seeds to fall onto the field surface. Below the rotating shaft is a device for leveling the field surface, combined with a device for making drainage ditches.

Compared with the traditional methods of broadcast and dense sowing in production, the 3-in-1 seeder has reduced the amount of seeds used by 40-50% (using 70-80kg/ha, compared to the actual amount of seeds used in production of 120-150kg/ha), reduced the amount of inorganic fertilizer by 15-20%, reduced 1-2 sprays of pesticides, and increased rice yield by 0.3-0.5 tons/ha (5-10%). The cluster sowing model has increased economic efficiency by 2-3 million VND/ha. The 3-in-1 row seeder also limits the situation of rice falling over when the rice is ripe and exposed to wind and heavy rain.

Chairman of the Farmers' Association of My Lac Commune - Le Hoang Khanh said: "Mr. Lung's innovation brings positive results, helping farmers save significant costs, not only reducing labor but also creating conditions for local people to learn and apply in practice".

It can be said that Mr. Lung's "3-in-1 rice seeder" contributes significantly to the sustainable implementation of the Project of 1 million hectares of high-quality and low-emission rice cultivation associated with green growth in the Mekong Delta by 2030. With this initiative, he won the Encouragement Prize in the 8th Long An Province Farmers' Technical Innovation Competition, 2023-2024./.

Le An - Phuong Thao

Source: https://baolongan.vn/nhung-sang-tao-huu-ich-cua-nha-nong-a186697.html

![[Infographic] Circular guiding the functions, tasks and powers of the provincial Department of Culture, Sports and Tourism and the commune-level Department of Culture and Social Affairs](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/6/29/877f24989bb946358f33a80e4a4f4ef5)

Comment (0)