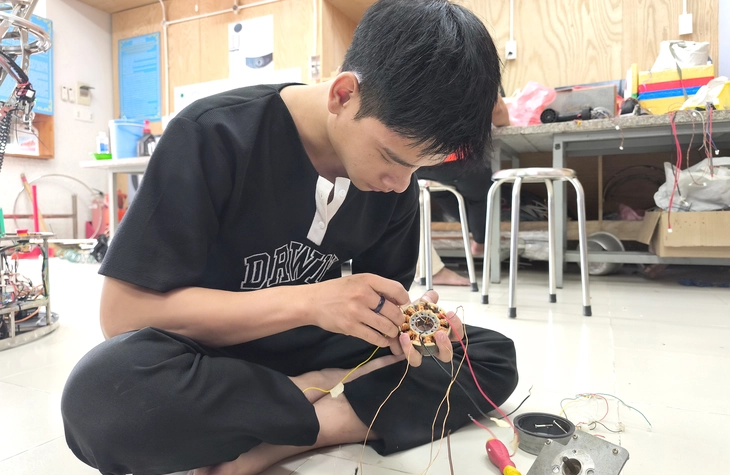

Bui Xuan Nguyen carefully wraps copper wires around the motor core - Photo: TRONG NHAN

Visiting Lac Hong University in early July, one can easily spot the vibrant atmosphere in a familiar corner of the campus, the "training ground" for robots as students prepare to enter the international Robocon competition.

Members of the LH-UDS robocon team are diligently making the final adjustments to their two robot "athletes" before heading to Mongolia to compete.

Attention to every detail

The group was divided into several small teams, each person in a different area, each with a specific task. Four mechanics were diligently disassembling and assembling the frame, welding machine parts, adjusting the wheels and joints for smooth operation. Two specialized in programming, two handled the motor windings, two others took care of the electrical part - the circuit board, and the remaining two were in charge of the control system, adjusting the handle according to user input.

Bui Xuan Nguyen is carefully wrapping copper wires around the motor core. This task may seem simple, but it requires extreme meticulousness. The wires must be uniform, and the distance between the windings must be precise. The winding speed will be adjusted to match the robot's design speed.

"Just a few millimeters of deviation can cause the motor to rotate erratically, affecting the robot's speed or throwing force," Nguyen explained while working. These copper wires are the core that controls the motor's speed, and in a competition like Robocon, even fractions of a second can make a difference.

Next to him, Mằn Kỳ Phúc was sitting in front of his laptop screen, his eyes glued to each line of code. They were diligently updating the robot control program to accommodate the new changes to the mechanical components.

"In addition, the image processing algorithm has been upgraded so that the robot can scan the board and identify targets better, especially the offensive robot which needs to aim precisely to shoot accurately from every angle."

"Robot basketball"

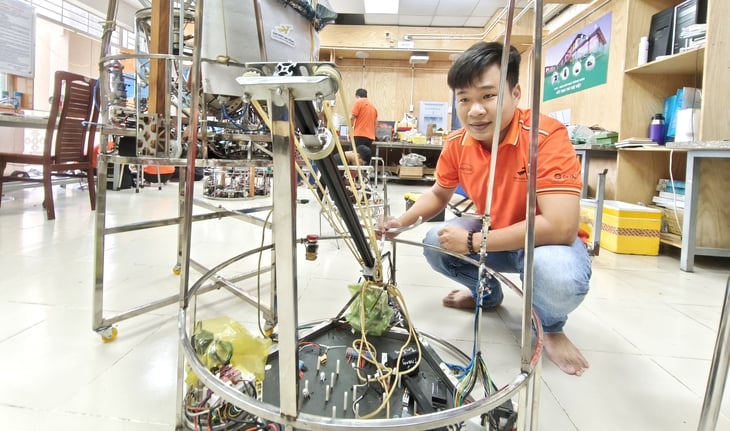

Captain Lam Quoc Tho introduces the new design for the relay unit of the defensive robot.

In 2025, Robocon will offer a completely new competition with a basketball-related theme. Instead of traditional mechanical challenges like climbing slopes, passing the ball, or shooting rings, this year the competing teams will enter a real "robot basketball" match, where two robots, one attacking and one defending, must coordinate seamlessly to score points.

Within the limited time of the game, the attacking robot's task is to shoot the ball into the basket from different scoring positions (2, 3, or 7 points), while the opponent's defensive robot will try to block the shot.

Lam Quoc Tho, the captain of LH-UDS, said that in matches, he will be responsible for controlling the defensive robot. This robot must be extremely fast and agile to intercept the opponent's ball. Even a slight delay will result in a loss.

After winning the national championship, the team sat down to figure out how to upgrade both robots – offensive and defensive. For the offensive robot, the team decided to add an extra wheel, increasing it from three to four wheels to improve maneuverability. However, the problem wasn't simple because, according to regulations, the total weight of both robots could not exceed 50kg.

"To add something, we had to subtract something else, so we changed the design of the defensive robot's ball-passing mechanism," Tho said.

Specifically, the ball-passing mechanism, which was previously a separate, rather heavy module, has been replaced with flexible elastic bands, significantly reducing weight and increasing flexibility. The team is racing against time to test the robot's performance after the improvements, checking for any errors so they can be adjusted before the July 28 deadline, the date the robot must be shipped to Mongolia.

"Now that we've sent the robot, we have to wait until the end of August to meet again on the international stage. So now is the time to do our best so we have no regrets," Tho said.

Mằn Kỳ Phúc diligently edited the code, upgrading the robot's performance.

The LH-UDS team from Lac Hong University is preparing to enter the ABU Robocon finals in Mongolia - Photo: TRONG NHAN

A playground for engineering and technology students.

The ABU Robocon (Asia-Pacific Robot Contest), organized by the Asia- Pacific Broadcasting Union since 2002, is a leading competition for engineering and technology students from countries in the region.

Each year, participating countries take turns hosting a unique competition theme, requiring their self-designed robots to perform a series of highly technical and tactical tasks. The reigning ABU Robocon champion is The Chinese University of Hong Kong, with an impressive victory in the Quang Ninh - Vietnam competition held in August 2024.

Vietnam has won this competition seven times, in 2002, 2004, 2006 (Ho Chi Minh City University of Technology, Vietnam National University), 2014, 2017, 2018 (Lac Hong University), and 2015 ( Hung Yen University of Technology and Education).

The competition is very high.

Lecturer Nguyen Dinh Dai, from the Faculty of Mechanical and Electrical Engineering at Lac Hong University, was impressed with the students' work ethic during this year's exam season. "They almost dedicated all their time to the robots. There were days when they were in the workshop from early morning until late at night, only taking a short break at lunchtime before continuing to fine-tune each detail," he said.

Regarding the upcoming ABU Robocon finals in Mongolia, Mr. Dai assessed this year's competition as highly competitive. Teams from Japan, China, Hong Kong, etc., remain formidable opponents. These teams possess very strong technological foundations, especially in image processing capabilities. Their robots analyze quickly and accurately identify the basket, resulting in a very high shooting accuracy rate.

Source: https://tuoitre.vn/vao-lo-luyen-robot-di-thi-quoc-te-20250715102055545.htm

Comment (0)