In mid-August 2025, during a working trip with the GIZ Energy Support Program to the Quang Ninh coal region, our group of reporters had the opportunity to visit Nui Beo Coal Company, a unit under the Vietnam National Coal - Mineral Industries Group (TKV).

Coal industry actively innovates technology in production activities

Gone are the dusty, hot coal mines of the past. Now, this place is covered in a cool green color. The roads are clean as if they had never been the site of mining activities.

Witnessing the transformation of the coal mining industry, especially when the open-pit mining model was converted to underground mining, Mr. Pham Ba Tuoc, Deputy Director of Nui Beo Coal Company confided: In the past, when we were still mining open-pit coal, we often did not dare to wear white shirts to work because the surroundings were full of dust. But now everything is different, the road from the mine to the operator's house is green and clean.

Contributing to these changes are a series of technological solutions that the company has boldly invested in. Dust suppression misting systems are installed at screening clusters, coal warehouses, repair workshops and on many coal transportation routes.

In particular, in 2023, 3 modern, automatic high-pressure misting systems were put into operation in the screening house and central coal warehouse area, helping to reduce dust, limit noise, and protect the environment for neighboring residential areas.

In parallel, a series of trees were planted at the North Chinh landfill, the landfill of Sidewalk 14, 11 or the +12 South Sidewalk 1 site, creating a natural shield against dust and noise.

Not only dust treatment, wastewater problem is also raised with fundamental solutions. Nui Beo Company is assigned by TKV to manage and operate the wastewater treatment system with a capacity of 1,200 m³/hour, applying lamella sedimentation and manganese filtration technology. All wastewater generated from the mining process is collected and treated to meet standards before being discharged into the environment.

Mr. Nguyen Manh Chuyen, Deputy Head of the Environment Department, TKV said that in the period of 2025 - 2030, TKV aims to become a strong economic group, playing an important role in the development of the economy, as well as continuing to affirm its pivotal position in ensuring national energy security. At the same time, develop sustainably, in harmony with the environment and carry out comprehensive digital transformation.

"In the period of 2020 - 2024, the Group has invested nearly 85,000 billion VND in key projects such as underground coal mining, processing, consumption, minerals, electricity, mechanics, mine chemicals and infrastructure serving production" - Mr. Nguyen Manh Chuyen informed.

Image recorded at Nui Beo Coal Company in August 2025

Accordingly, key underground coal mines such as Khe Cham, Mao Khe, Nui Beo, Vang Danh... have been invested in and expanded, applying synchronous conveyor systems, ventilation, drainage and centralized control, gradually replacing manual labor, improving safety and productivity. In the mineral sector, TKV focuses on deep processing to increase product value.

Identifying mechanization, automation and digital transformation as breakthroughs, the Group has so far put into operation dozens of coal cutting machine systems, self-propelled support racks, and continuous covered conveyor belts. Thanks to that, underground mining productivity has increased by 10-15%, saving hundreds of billions of VND in costs each year.

In addition, applying centralized production management system (Dispatching), applying digital technology in monitoring mine safety, managing coal consumption and business administration. Some coal companies are also pioneering in applying artificial intelligence (AI) in monitoring mine environment, automating conveyor belt operation and managing transportation vehicles.

In addition to growth targets, TKV also focuses on environmental protection and sustainable development. Many environmental treatment projects have been implemented, such as a mine wastewater treatment system with a capacity of tens of thousands of m³/day; planting trees to restore the environment after mining and installing automatic monitoring equipment...

Clearly, from an industry that has been associated with a heavy image and potential risk of pollution, the coal mining industry is proving that technology is the path to change, both improving production efficiency and helping businesses firmly step on the path of sustainable development.

The "wave" of investment in technology application has been taking place in many Vietnamese enterprises, becoming the "key" to help enterprises create competitive advantages.

TH Group is a typical example of high-tech agricultural development.

“Seeing with our own eyes” the model of TH Group’s high-tech farm, factory, and agricultural fields in Nghe An province, we were surprised by a series of the world’s most modern technologies being applied here.

According to TH Group, when starting to implement the project of "high-tech industrial-scale concentrated dairy cow farming and milk processing" worth 1.2 billion USD in Nghe An, TH Group took advantage of the achievements of science and technology, management science and artificial intelligence of the world, turning TH True Milk into a model of green economy, knowledge economy, and circular economy.

For example, TH applies Israel’s Afifarm herd management technology - a world-leading modern dairy farm management system. Cows are tagged and have Afitag electronic chips attached to their legs to monitor their health, nutrition and milk production. All information of each individual cow is analyzed and used by farm managers to make management decisions for the entire farming cycle on the farm.

TH farm also creates rations, mixes, processes and supplies feed for dairy cows completely automatically by 100% computerization under the consultation and management of Israeli nutrition experts using Skiold software technology - Denmark.

From 2021, TH Group also began deploying an AI camera eye system that allows automatic monitoring of the number of cows eating, control of food intake, and monitoring of cow health while in the barn...

TH also applies modern, high-capacity agricultural machinery in cultivation, such as a combined harvester (cutting, grinding, spraying onto trucks) with a record speed of 2 tons/minute. The highest harvesting speed has reached 3,000 tons/day, which, compared to manual labor, is equivalent to a thousand people working in one day...

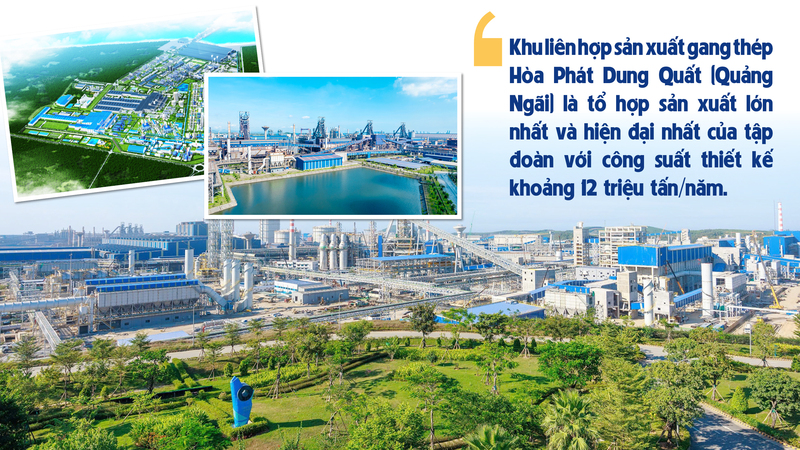

Hoa Phat Group has used leading advanced technology lines.

In the field of steel production, a representative of Hoa Phat Group said that with a total capacity of 15 million tons of crude steel/year, Hoa Phat has applied modern blast furnace technology, closed-loop circulation from upstream iron ore to billets, hot-rolled steel coils, construction steel, high-quality steel of all kinds serving the mechanical engineering industry, structure, construction industry, railways, etc.

The Group owns 2 modern, synchronous iron and steel production complexes and 1 steel production complex. Of which, the Hoa Phat Dung Quat Iron and Steel Production Complex (Quang Ngai) is the largest and most modern production complex of the Group with a designed capacity of about 12 million tons/year.

The complex has a scale of 700 hectares, total investment capital of about 7 billion USD, using leading advanced technology lines from European and G7 countries, ensuring the lowest energy consumption, optimizing production costs.

Thanks to large and systematic investments in modern technological lines, Hoa Phat Group has created high quality products that are competitive in the international market, meeting the world's most stringent standards.

In particular, Hoa Phat is the only Vietnamese enterprise that invests in the production of hot-rolled steel coils and many types of high-quality steel, contributing to replacing imported goods.

High-quality steels are widely used in various manufacturing industries, present everywhere in life such as prestressed steel, steel for producing bead, automobile tire belt, making screws, welding rod cores, steel for making oil pipes, steel pipes, galvanized steel, manufacturing household appliances, refrigeration, electric motors, etc.

Currently, Hoa Phat not only holds the No. 1 market share position in construction steel and steel pipes in the domestic market, but also exports steel to 40 countries and territories.

It can be seen that the common point of the above enterprises is that they consider technology as a “bridge” to overcome traditional barriers, opening up a new game, where added value comes from innovation and creativity, not simply from physical labor or available resources. At the same time, from these stories, it can be seen that what enterprises need to change is not only in terms of technology but also in terms of management thinking and long-term development strategy.

Mr. Pham Van Quan, Deputy Director of the Department of Industry, Ministry of Industry and Trade, commented that the application of new technologies is on the rise and opens up many opportunities for the manufacturing industry. Many large enterprises have pioneered the construction of smart factories, applying AI and IoT to optimize performance. The level of automation is very high in some leading enterprises such as Vinfast, Hoa Phat, Thaco, TH Truemilk...

Specifically, businesses have applied AI to analyze real-time data to monitor machine performance, predict failures and provide early warnings; use AI-integrated cameras to check product errors, analyze causes for timely correction. At the same time, synchronize big data with production plans for effective energy management.

IoT is being applied to automate processes from supply chain management to supply chain tracking, thereby minimizing operational errors, optimizing material usage and increasing labor productivity. "Thanks to these applications, some factories in Vietnam have achieved higher levels of precision and flexibility, approaching the standards of smart factories in the world," said Mr. Pham Van Quan.

(To be continued)

Source: https://congthuong.vn/khoi-hanh-cung-cong-nghe-doanh-nghiep-but-toc-trong-ky-nguyen-so-bai-2-don-song-dau-tu-417623.html

![[Photo] Red flag with yellow star flutters in France on National Day September 2](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/28/f6fc12215220488bb859230b86b9cc12)

![[Photo] General Secretary To Lam attends the opening ceremony of the National Achievements Exhibition](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/28/d371751d37634474bb3d91c6f701be7f)

![[Photo] National Assembly Chairman Tran Thanh Man holds talks with New Zealand Parliament Chairman](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/28/c90fcbe09a1d4a028b7623ae366b741d)

![[Photo] Politburo works with the Standing Committee of Cao Bang Provincial Party Committee and Hue City Party Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/28/fee8a847b1ff45188749eb0299c512b2)

Comment (0)