|

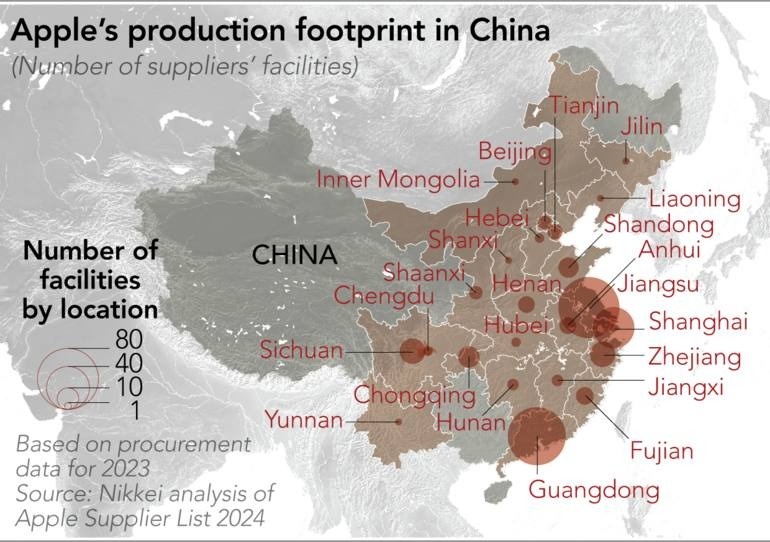

Tariffs have yet to force Apple to produce iPhones in the US. Photo: Nikkei . |

Amid the tariff looming, Apple’s first response was not to ramp up production in the U.S. Instead, the company quickly pivoted to India and Southeast Asia.

In April, Nikkei reported that many of Apple’s partners in India had purchased additional iPhone manufacturing equipment. Even CEO Tim Cook stressed that the majority of iPhones sold in the US will be assembled in India, while “almost all” other devices including iPads, Macs, Apple Watches and AirPods are imported from Vietnam.

While the long-term strategy is unclear, the immediate reality is that President Donald Trump’s reciprocal tariffs will not bring iPhone production back to the U.S. This prospect remains remote despite Trump and Commerce Secretary Howard Lutnick’s repeated assertions to the contrary.

Complex supply chain

Despite increased investment from Apple and many other companies to diversify their supply chains, India and Southeast Asia have struggled to compete with China, which has a large and efficient supply chain.

Apple has diversified its supply chain since Trump’s first term, when US-China trade tensions escalated. But Nikkei figures show that as of 2023, about 84% of Apple’s top 187 suppliers will still have supply bases in China.

During the same period, the number of Apple suppliers in other countries included Vietnam (35), Thailand (24) and India (14). Expansion plans are limited by labor shortages, rising costs, language and cultural differences, as well as tightening customs checks when exporting equipment and manufacturing materials from China.

|

Apple's supply bases in China. Photo: Nikkei . |

Shifting entire supply chains is difficult. For example, some MacBooks, Mac minis, and iMacs labeled “Made in Vietnam” or “Made in Thailand” do not necessarily mean that all components were produced and assembled in the country.

For example, with printed circuit boards (PCBs), Apple's major suppliers invest in surface mount (SMT) lines, assembly and testing for MacBooks, Mac minis in Vietnam, and iMacs in Thailand. SMT is the process of attaching processing chips and peripheral chips to PCBs - one of the most expensive components of a device.

Still, some MacBook, Mac mini, and iMac motherboards are being shipped back to Chengdu, Shenzhen, and Shanghai for final assembly, industry sources said, because it’s not feasible to ship some components out of China, including metal cases, mechanical parts, and connectors.

“For example, the MacBook's metal case uses a single piece of molding with just a few screws, which is more complex and difficult to assemble than other laptops.

This requires specialized metal casting machines, along with skilled technicians and workers, which can only be found in China in sufficient quantities,” said the director of a MacBook parts supplier.

Difficulties in labor and costs

CEO Tim Cook has stressed that China's manufacturing advantage is not just about cost.

“In the US, you can have a meeting with machining engineers, but I’m not sure we can fill a room. In China, we can fill multiple football fields,” Cook said.

For the iPhone, which has at least 1,500 components and parts, it is more difficult to assemble than a MacBook. David Dai, a technology analyst at Bernstein Research , admits that it is difficult for any component maker with a gross profit margin of less than 20% to move production to the US. One reason is the number of workers.

|

MacBook Air M2. Photo: Bloomberg . |

“In reality, you can’t find enough people for these jobs in the U.S.,” Dai said. “India is an example of how difficult it is to shift production to a new location. Apple had hoped to move some of its iPhone assembly to India. But years later, India’s share of iPhone production is still less than 20 percent.”

Wages are another issue. Counterpoint Research analyst Ivan Lam said high labor costs and tariffs would not be enough to convince Apple to manufacture iPhones in the US.

“The final assembly of the iPhone is unlikely to take place in the US, let alone the entire electronics supply chain. Just compare the average wage of manual labor in Zhengzhou, China, with that in Detroit, Michigan, and you will see that the cost is many times higher,” Lam said.

Partner's dilemma

Most consumer electronics are still made in China. The country produced 64% of the world’s smartphones last year, along with 79% of laptops and 72% of TVs, according to Counterpoint Research .

While geopolitical tensions and tariff uncertainty are expected to accelerate the shift away from China, another reason brands are holding back from assembling in the U.S. is the uncertainty of Mr. Trump.

One of the big questions, according to Nikkei , is what happens after the 90-day reprieve from the reciprocal tariffs ends. Suppliers are still waiting for the Trump administration to announce separate tariffs on smartphones and laptops.

Company executives are open about the challenges. Paul Peng, president of display maker AUO and chairman of the Taipei Computer Association, said supply chain operating costs rose 10 percent when customers asked to build alternative networks in Vietnam. Since then, facilities have had to do a lot to reduce operating costs.

“If we move production to the US, the cost structure won't be 10%, it could be 100% or higher,” Peng said.

|

iPhones on display at an Apple store in China. Photo: Bloomberg . |

According to him, the US does not have a solid foundation for manufacturing technology or building a strong supply chain, and its operational efficiency is not as good as Asia's.

“TSMC is a good example. It took them four years to build a factory in Arizona, while it only took 18 months in Taiwan,” Peng stressed.

TH Tung, Chairman of Pegatron, the company that assembles iPhones, said that the US is an important market but does not represent the whole world .

“We should not let tariff uncertainty disrupt our supply chain strategies in other markets,” Tung added.

Stan Shih, founder of Acer, recalls that when he first started his company, he was asked by customers to manufacture some products in the U.S. However, the company refused because it could not make a profit.

“Suppliers should be calm. You may not choose this strategy if manufacturing in the US is a loss-making one,” Shih stressed.

Source: https://znews.vn/ly-do-ong-trump-chua-the-khien-apple-dua-iphone-ve-nha-post1550662.html

Comment (0)