A research team in South Korea has developed a new method to make lithium-metal batteries safer, more durable, and closer to commercialization. This research opens up hope for the future of electric vehicles and large-scale energy storage.

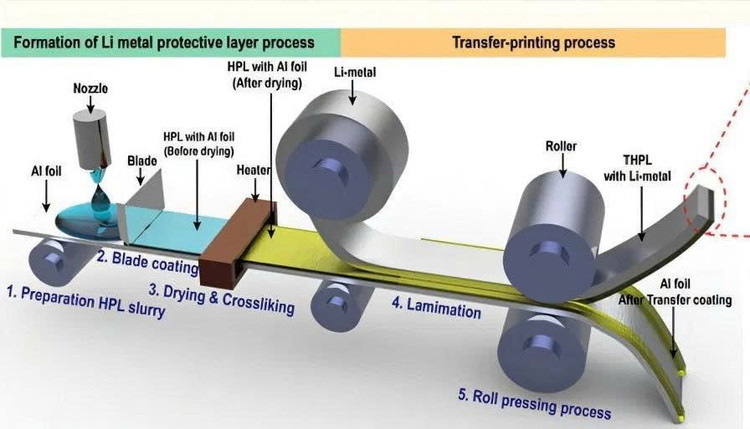

Led by Dr. Jungdon Suk at the Korea Institute of Chemical Technology (KRICT), the research team invented a special “transfer printing” technique.

This technique allows for the creation of a protective layer on the lithium surface without using toxic chemical solvents or damaging the sensitive lithium layer — a major challenge that has slowed the development of lithium–metal battery technology for years.

Lithium–metal Batteries: The New Energy Revolution?

Unlike conventional lithium-ion batteries that use graphite cathode, lithium-metal batteries use pure lithium, which has 10 times the energy density — allowing more energy to be stored in a significantly smaller and lighter battery.

This is the core technology for advanced batteries such as solid-state batteries and lithium–sulfur batteries. However, metallic lithium has a fatal weakness: during charging/discharging, tiny needle-like fibers called dendrites can grow on the lithium surface.

When they grow large enough, they can cause short circuits, fires, or complete battery failure. The breakthrough approach from Korea is that they used an indirect method.

Prototype Lithium-metal battery developed by the research team. Photo: KRICT – Jungdon Suk

Traditionally, to prevent dendrites, protective coatings are applied directly to the lithium using liquid solvents — but this can easily contaminate and damage the lithium surface, making mass production extremely difficult.

The KRICT team turned this process on its head. They pre-form the protective layer on another surface, then gently “stick” it to the lithium with pressure — kind of like applying a sticker.

The method is called roll-to-roll transfer printing. It’s clean, scalable, and doesn’t damage the lithium. They designed two types of protective layers, one made of an alloy of aluminum oxide and gold. The other is a hybrid material made of ceramic and flexible polymer.

Both are only about 5 micrometers thick, but can cover large areas, preventing dendrites from growing and helping lithium ions move more efficiently between the electrode and the electrolyte.

In tests, protected batteries retained more than 81% of their capacity after 100 charge cycles—twice as much as unprotected lithium—and remained stable even during rapid charging.

Lithium-ion batteries are extremely popular, but the risk of explosion is the most worrying problem today. Photo: Gen AI

The team successfully created a battery prototype measuring 245 × 50 mm, equivalent to half the size of a AAA battery. This proves that it is suitable for industrial-scale production.

Scientists believe that this method could accelerate the commercialization of lithium–metal batteries, especially for electric vehicles and large-scale energy storage systems, and could also be applied to new battery technologies such as solid-state batteries and lithium–sulfur batteries.

“This is one of the most practical solutions to realize high-energy lithium-metal batteries,” said Dr. Young-Kuk Lee, Chairman of KRICT, emphasizing the technology’s potential to enhance Korea’s position in the global battery supply chain.

Source: https://khoahocdoisong.vn/pin-lithium-kim-loai-xoa-noi-lo-chay-no-post2149042593.html

Comment (0)