The Vietnam International Innovation Exhibition 2023 was held in Hanoi , right on the premises of the National Innovation Center (NIC Hoa Lac) and was inaugurated by the Prime Minister and leaders of ministries and branches.

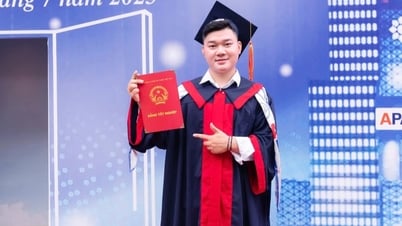

Exhibition visitors learn about high-tech scientific applications in agricultural production of TH Group.

Participating in the exhibition as a representative of a high-tech agricultural enterprise, TH Group introduced modern technologies that are being successfully applied by this enterprise in the Group's agricultural sector, especially at the High-tech Concentrated Farm Cluster with the world's largest closed-scale production process (recognized by the World Record Alliance in 2020).

Application of artificial intelligence in dairy herd management

In Vietnam, in 2009, when the Industrial Revolution 4.0 was still a new concept, with the steadfast vision and outstanding management thinking of Labor Hero Thai Huong, right from the first steps, TH applied high technology and artificial intelligence in cow herd management, applied science and technology in mixing rations at the Feed and Nutrition Center, SAP management system in administration, green technology to reduce greenhouse emissions... to build a sustainable production chain "from green pastures to clean glasses of milk".

The combination of high technology and 4.0 management science helps to bring stable and tightly controlled output and quality of fresh milk, reducing costs, prices and sustainable development.

A chip worn on cows' legs can help detect bovine mastitis 4 days in advance for immediate isolation and treatment.

Currently, TH farm applies Afifarm management technology (from SAE Afikim Company, Israel). This is one of the most modern technologies in the world for dairy cow management. This technology can detect cow health problems at an early stage through the AfiTag chip attached to each cow's leg. Thanks to that, TH's herd of nearly 70,000 cows is always monitored for health in real time, detecting estrus automatically and accurately, optimizing mating time. TH can even detect bovine mastitis 4 days in advance for immediate isolation and treatment.

Notably, TH Group also deployed an AI camera system to support herd monitoring and management. The system counts the number of cows eating in each area, then automatically adjusts the fan and misting capacity to suit the needs, helping to save on electricity, water and wastewater treatment costs. If there is too little food in a particular barn, the system will issue a warning to promptly provide enough food for the herd.

At the exhibition, TH also introduced some typical herbal tea and beverage products.

At TH farm, the ration creation, mixing, processing and supply of feed for dairy cows is 100% automated by computerization under the consultation and management of Israeli nutrition experts using Skiold software technology (Denmark), helping to control the import of concentrated feed ingredients, grinding, and mixing of concentrated feed formulas; or NDS Professional technology (Nutritional Dynamic Sys- tem) from Italy helps to create nutritionally appropriate feed rations, quantifying for each individual cow... Currently, TH's Feed and Nutrition Center mixes an average of 2,000 tons of feed per day.

TH Group pays special attention to cow feed ingredients. TH applies artificial intelligence and big data in growing animal feed. All plots of land in TH fields are synchronized into the GPS and Google Map systems to determine the optimal farming direction for high-capacity machinery.

TH currently has 15 modern automatic irrigation systems, each system is 350-550 m long, integrating effective fertilization features.

Green Technology Towards Net Zero

Aiming towards the Net Zero goal and fulfilling its commitment to the Government, TH Group uses high technology and green technology to reduce greenhouse gas emissions, effectively manage energy in factories, and use renewable energy...

Since 2020, TH Group has implemented a rooftop solar power project. The system helps save 29,000 kWh/month, contributing to significantly reducing emissions into the environment. In 2022 alone, TH farm connected to the grid approximately 7 million kWh (meeting nearly 10% of the electricity consumed at the farm unit), equivalent to reducing more than 4,500 tons of CO2 /year...

Solar power on the roof of TH dairy farms

Currently, TH Group has applied the green economic model and circular economy to all stages of the livestock, crop and production process. A typical example is the construction of a system to treat cow manure and wastewater. Every day, cow waste is collected, dehydrated and dried before being processed, the volume is about 400 tons after drying.

In addition to dried cow waste, the raw materials for organic fertilizer production also include leftover food, sugarcane bagasse and biological sludge generated during the wastewater treatment process of farms. This shows that the by-products of the livestock farming process on TH Group's farms are all used as raw materials for fertilizer production, affirming the Group's policy of developing a green economy and a circular economy.

Source link

Comment (0)