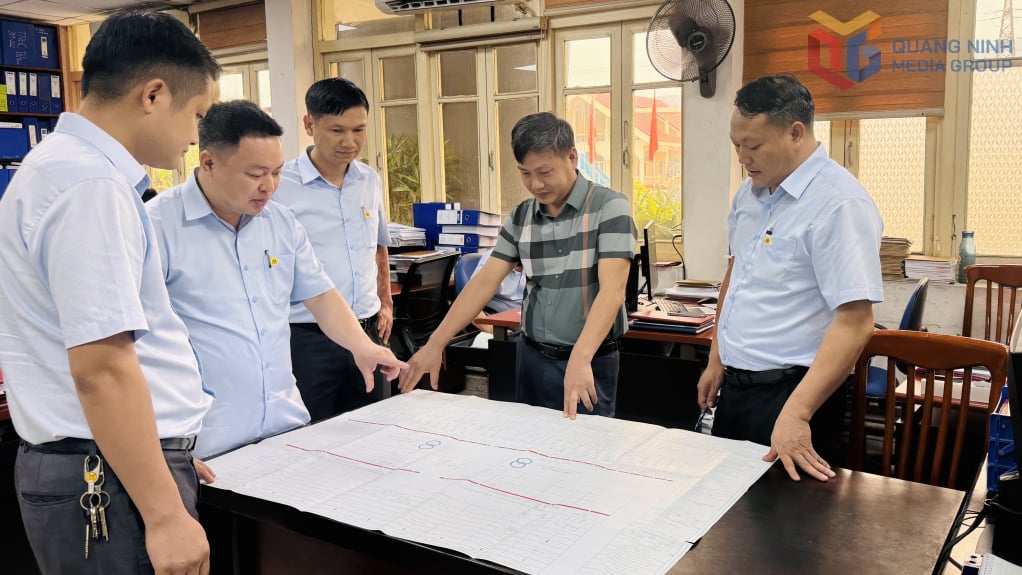

For many years, in the process of building the mining chart, the mine's engineers have researched, surveyed and detailed the time to transport coal, rock, materials and labor. The deeper the mining, the more carefully it is calculated, ensuring production efficiency and labor safety. Realizing that shortening the time and reducing labor in the transportation stage will help the mine maximize productivity and output, especially the transportation of coal and rock from the furnace to the surface. Since 2017, Mao Khe Coal has conveyorized the entire coal transportation stage from the furnace mirrors to the coal processing warehouse.

According to the unit's leaders, Mao Khe Coal has gradually switched from transporting coal by wagon to conveyor belts. Accordingly, the unit is using 18 conveyor belts to continuously transport coal from the mine to the industrial mine site. At the same time as investing in equipment, the unit has also researched and applied an automated system to centrally control conveyor belts, transporting coal underground and on the ground.

The advantage of this system is that all signals and operating parameters of each conveyor will be transmitted to the control center.

After many years of use, the system has helped optimize the number of workers operating conveyor lines, reducing from 45 workers operating/day and night of production to 12 workers.

Worker Lam Van Khanh, Transport Workshop 2, Mao Khe Coal Company - TKV said: From this central control house, the operator will monitor the entire operation of 15 conveyor lines, promptly remove impurities mixed in the coal, and at the same time identify each location at risk of incidents to coordinate the fastest solution, ensuring safety during the production process...

Particularly for the work of transporting people to production locations in the mine, Mao Khe Coal is making maximum use of suitable transportation equipment systems to transport workers, and is committed to not having workers have to walk more than 500m to the production site.

According to Mr. Nguyen Thanh Phong, Deputy Head of the Transportation Electromechanical Department, the Company has put into operation 1 MDK winch system at the main shaft, with a transport capacity of 300-350 people/hour; 9 winch systems supporting pedestrians, with a capacity of 270-300 people/hour. In addition, the Company has also invested in 50 18-seat double-decker buses to support workers moving closer to their work locations.

These vehicles help workers save time, especially reducing human effort in the process of moving from the furnace door to the production locations, in 20-25 minutes, much shorter than before. Improved travel conditions have helped Mao Khe miners ensure their health and focus maximum time on production, thereby increasing coal output.

Thus, Mao Khe Coal is currently applying continuous transportation systems to serve the transportation of coal, materials, equipment and labor, including: Coal transportation by scraper system, conveyor belt from inside the mine to outside; transportation of soil and rock by excavator onto wagon, pulled by battery electric train and traction shaft; transportation of materials and equipment by winch combined with wagon and specialized loader and transportation of labor by cable winch combined with twin-swing.

Currently, in addition to the task of ensuring the completion of the output of over 2.5 million tons of coal/year, Mao Khe Coal is also actively accelerating the progress of the vertical shaft pair of the underground mining project below -150m. Therefore, this is considered a project of decisive importance to the development of Mao Khe Coal Company.

Recognizing the importance of the project, right from the beginning of its implementation, Mao Khe Coal Company has paid attention to modernizing the transportation system. With the new mining model, the mine will go deep by vertical shaft. According to the project design, the Company will invest in a system of shafts to transport people, materials, coal and soil and rock.

"In TKV, the vertical shaft loading system has been widely applied in many mines with similar mining technology. Therefore, this is a favorable condition for Mao Khe Coal to absorb the advantages of the system, and at the same time, be one step ahead in training human resources to operate and master transport equipment" - Mr. Doan Viet Tuan, Deputy Director of the Company added.

Modernizing underground transportation work at Mao Khe Coal in particular and underground coal mining units of TKV in general is also an important part of the Group's technical and technological development strategy until 2030, aiming to "Continuously innovate and modernize technology towards improving the level of mechanization, automation, computerization and cleaner production"; and is being increasingly promoted to concretize Resolution 57 of the Politburo on breakthroughs in science and technology development, innovation and national digital transformation.

This is an inevitable trend and at the same time an optimal condition for Mao Khe Coal in particular and the Group's underground coal mining activities in general to approach the goal of building a smart, modern, high-output and safe underground mine.

Source: https://baoquangninh.vn/hien-dai-hoa-cong-tac-van-tai-ham-lo-o-than-mao-khe-3362977.html

![[Photo] Nghe An: Provincial Road 543D seriously eroded due to floods](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/5/5759d3837c26428799f6d929fa274493)

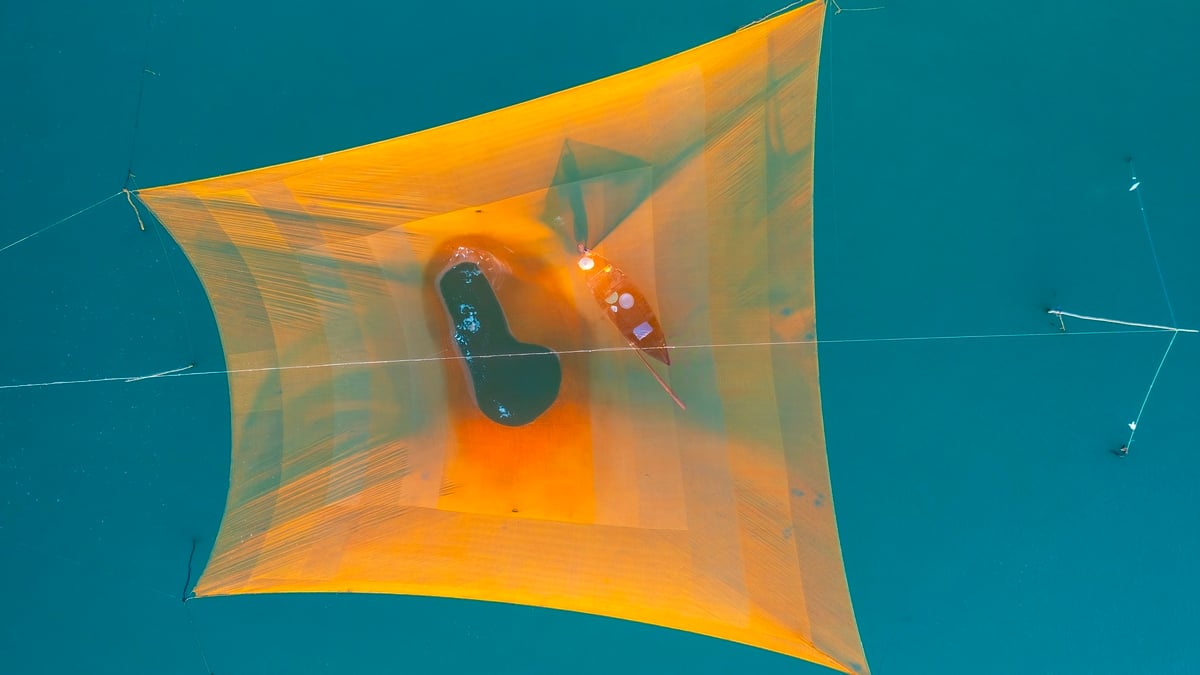

![[Photo] Discover the "wonder" under the sea of Gia Lai](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/6/befd4a58bb1245419e86ebe353525f97)

Comment (0)