|

The Pura 80 series is displayed in a Huawei store in Beijing, China. Photo: Reuters . |

According to Nikkei 's analysis, Huawei has increased the proportion of domestically produced components in its new smartphone models to nearly 60%. Recently, the Chinese company has made new strides in the production of processors and memory chips, in order to cope with US export restrictions.

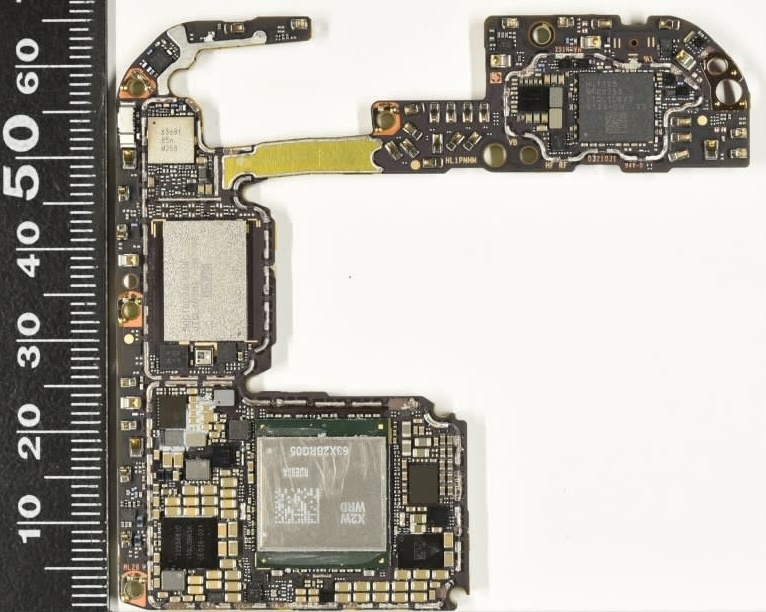

With assistance from the Japanese product teardown company Fomalhaut Techno Solutions, Nikkei disassembled two high-end Huawei phones: the Mate 70 Pro (released in 2024) and the Pura 80 Pro (released earlier this year).

There is still a gap.

The cost of components was analyzed and compared to the estimated total cost and the cost of its predecessor. Accordingly, components manufactured in China for the Mate 70 Pro accounted for 57% of its value. The Pura 80 Pro also recorded a similar figure, with a total component cost of $380 .

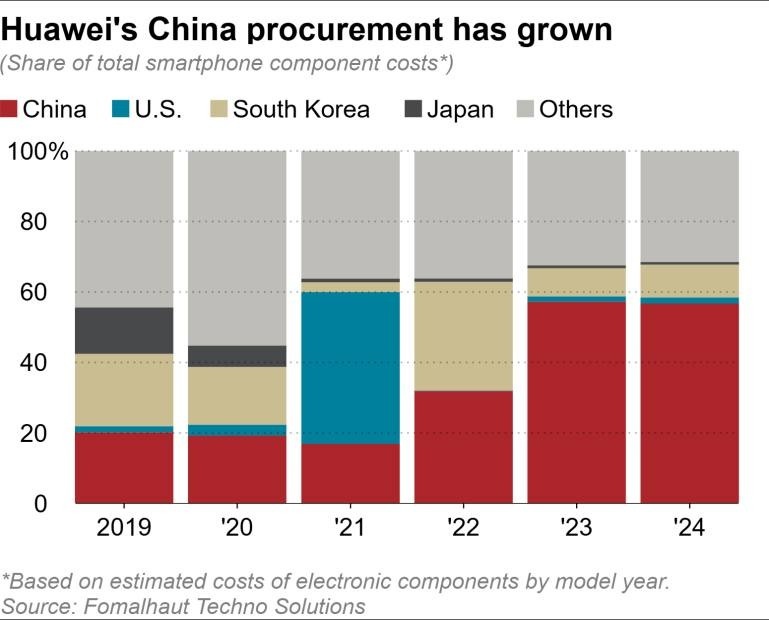

For Huawei smartphones in the same segment but launched in 2020, the percentage of domestically sourced components was only 19%. This figure increased to 32% in 2023. By 2024, the percentage of components from Japan, the US, and South Korea decreased by a total of 20 percentage points.

Huawei's increased reliance on domestically produced components coincided with US export restrictions. In 2019, the first administration of President Donald Trump banned US companies from engaging in transactions involving electronic components and software with Huawei. A year later, the regulation was extended to companies outside the US.

|

The proportion of Chinese components in the total production cost of Huawei smartphones during the period 2019-2024. Photo: Nikkei . |

Unexpectedly facing difficulties in sourcing components from abroad, Huawei quickly built a domestic supply chain. For the Pura 80 Pro's System-on-a-Chip (SoC), the company uses the Kirin 9020 chip designed by its subsidiary HiSilicon.

Many sources indicate that the Kirin 9020 is manufactured using a 7nm process, the same as the chip in the iPhone 11 released in 2019. A smaller process means higher processing performance and lower power consumption.

"Even so, Huawei is still more than five years ahead," emphasized Akira Minamikawa, a senior consultant at market research firm Omdia .

Satoru Oyama, a representative of the Japanese semiconductor consulting firm Grossberg, noted that Chinese companies have the capability to design chips, but face numerous challenges in the mass production phase.

Reduce dependence on foreign countries.

According to Nikkei , analysis of components in the new smartphones reveals China's progress in manufacturing expensive components such as memory chips.

For short-term storage memory like DRAM, Huawei has shifted from importing to purchasing chips manufactured by ChangXin Memory Technologies. For long-term NAND storage memory, Huawei uses products from Yangtze Memory Technologies.

Huawei also purchases OLED screens from BOE Technology Group, at an estimated cost of $64 . According to Minatake Kashio, CEO of Fomalhaut, most of the critical components in the product are manufactured in China, bringing Huawei closer to using domestically produced components in its devices.

|

Huawei is increasingly using domestic solutions for expensive components such as CPUs and memory. Photo: Fomalhaut Techno Solutions . |

Alibaba, one of the driving forces behind China's tech industry, is also designing its own AI chips for robots and self-driving cars. Some startups, such as Moore Threads (founded by former Nvidia executives) and MetaX, have even gone public to raise capital.

In the chip manufacturing equipment sector, startups like SiCarrier are gaining more traction thanks to their strategy of covering the entire initial process of chip manufacturing, including circuit board design.

Naura Technology Group, which specializes in manufacturing chip-making machinery, has also expanded its business with a wide range of products, and its market capitalization is even higher than that of Japan's Disco.

To cultivate talent in advanced technology fields, the Chinese government is attracting researchers from both within and outside the country, many of whom have experience working in various nations. They are brought to top universities in the country through research funding.

According to Canadian research firm TechInsights , China's domestic semiconductor supply reached 23.3% in 2023, an increase of 8.4 percentage points over the past 10 years.

Source: https://znews.vn/thanh-tuu-moi-cua-huawei-post1614352.html

Comment (0)