In a paper published in the peer-reviewed journal ACS NANO by the American Chemical Society on August 20, the researchers wrote: "Bamboo, known for its rapid growth, regeneration, biodegradability, and environmental friendliness, is considered a promising alternative to plastics."

Plastic pollution has become a serious global concern, and the very slow biodegradation of traditional plastics has led to alarming accumulation of plastic waste in soil, water sources, and even human bodies.

China, which has more bamboo forests than any other country, is in the midst of a long-term effort to reduce pollution and become carbon neutral. It is also looking to turn bamboo into a viable, biodegradable alternative to plastic.

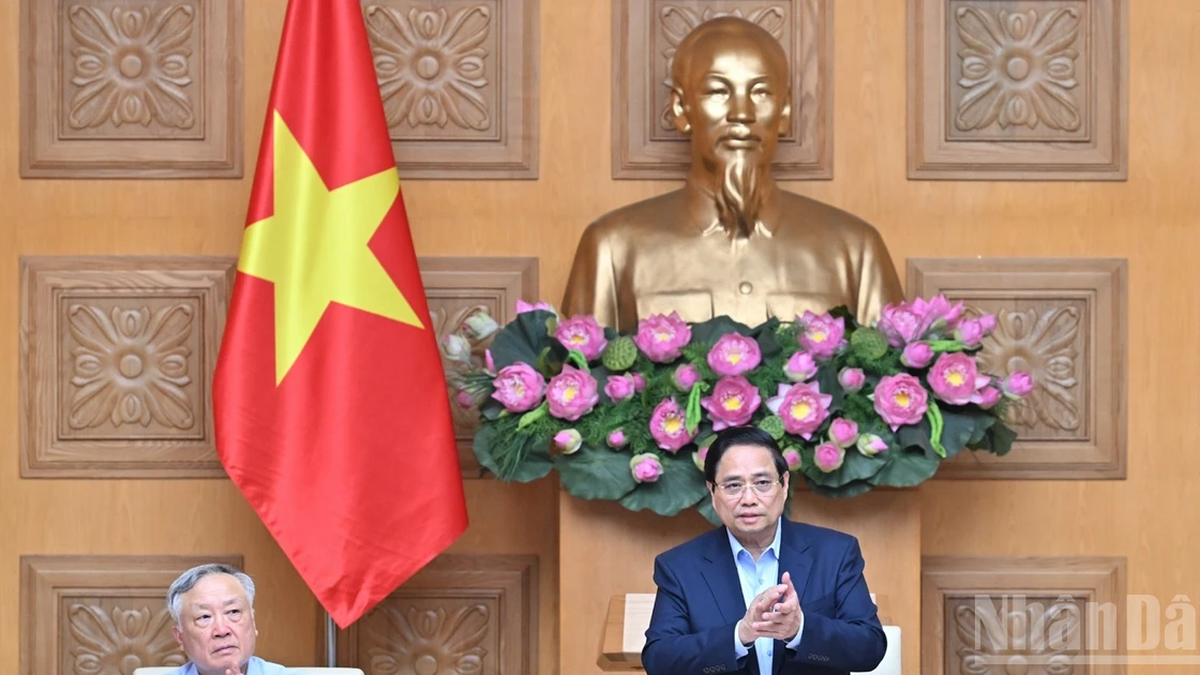

China is looking to tap into the rapid growth and biodegradability of bamboo to replace traditional plastic products. Photo: Shutterstock

However, significant technical challenges have prevented bamboo from being widely used as a replacement for conventional plastics. The natural plasticity and self-adhesiveness of bamboo cells are much lower than those of conventional plastics, forcing bamboo to be combined with other materials such as starch. This creates disadvantages such as poor mechanical strength, sensitivity to water, and processing costs.

To find a solution, the team developed a method to improve the flexibility of bamboo by altering its cell structure before hot-pressing it into a waterproof and recyclable plastic.

To produce bamboo-based thermoset plastics on an industrial scale, researchers grind the bamboo into powder and use environmentally friendly chemicals to remove some of the lignin — the organic substance that gives the plant its stiffness — and break down the crystalline structure of the cellulose.

The color of the resulting resin ranges from pale yellow to reddish brown depending on the amount of lignin remaining in the bamboo.

"This regeneration process not only significantly enhances the responsiveness of bamboo cells, but also significantly improves their plasticity," said researchers from the National Bamboo Research Center of China, Fujian Agriculture and Forestry University, and the Chinese Academy of Forestry.

Whole bamboo plastic is described as having “exceptional mechanical strength”, meaning it can be classified as a rigid plastic alongside traditional plastics such as polystyrene and polyvinyl chloride (PVC).

"Activated bamboo can be used to produce a variety of bamboo plastic products including spoons, hats, phone cases, headphone cases, computer cases and sinks, providing a wide range of applications," the research team said.

According to researchers, plastic made from bamboo also has good tensile strength, can retain its shape, as well as hardness when soaked in solvents and water.

Because the material does not melt during heating, it is considered a thermoset rather than a thermoplastic. Bamboo plastic can also be recycled by grinding it into a powder and mixing it with water before being hot-pressed again.

In underground tests, scientists found that bamboo plastic almost completely decomposed after 90 days.

“Thermosetting plastics made entirely from bamboo offer a promising solution to replace conventional plastics with sustainable alternatives and promote the use of bamboo resources,” the report said.

Hoai Phuong (according to SCMP)

Source: https://www.congluan.vn/lieu-tre-co-phai-giai-phap-cho-van-nan-nhua-hoa-thach-post309875.html

![[Photo] National Assembly Chairman attends the seminar "Building and operating an international financial center and recommendations for Vietnam"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/7/28/76393436936e457db31ec84433289f72)

Comment (0)