( Quang Ngai Newspaper) - Quang Ngai was once famous as the land of sugarcane. To make sugar, the sugarcane must first be pressed to extract the juice. To press the sugarcane, the ancients used a three-roller, toothed, circular cover (three-roller cover), or a "machine" with a pre-industrial character. Without a sugarcane cover, the sugarcane could not be pressed to make sugar and there could be no sugarcane land.

Such an essential technology, but the books about sugar cane industry so far only focused on describing the cover, not mentioning who made the cover, how to make it. Now it is impossible to find a cover maker. I went to the villages with a rich tradition of sugar cane production, met the old sugar cane workers to ask about cover making.

|

| Three men cover. |

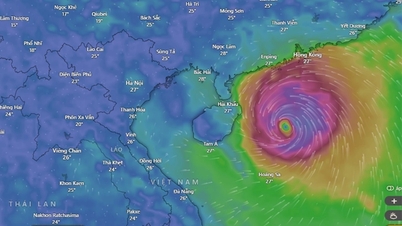

It is surprising to know that, although they are both working in the woodworking industry, making covers is a separate profession, not just carpenters who make cabinets or build houses. The person who specializes in making covers is called "the man who makes goods". Why is it called "the man who makes goods"? Because three covers stand in a row, in some places people call them "the man who makes goods". The structure of the cover is not too complicated, including three covers which are 3 round wooden pieces standing next to each other, with a rectangular frame on the outside holding them up, at each cover, the upper part has two rows of teeth to transmit the rotation force, the lower part is smaller with a gap to put the sugarcane in to press. From the empty cover in the middle there is a high neck to hang the "yoke" - a sturdy piece of wood outside, the yoke is attached to the shoulder of the buffalo (or cow) to push the cover to rotate.

|

| Sketch the full cover. |

Is it easy or difficult to make such a cover? The answer is: Difficult right from the wood material stage. According to those who directly cook sugar, sugarcane covers are very "choosy" about wood, specifically the wood must be flexible and sturdy to withstand the very heavy rotation force, ensuring that the teeth and the cover do not crack. People can use ke wood, cam xe wood to make covers, but they are not really sturdy, only rotating wood is the most optimal. In the past, Quang Ngai province was covered with vast forests everywhere, there was also rotating wood, but it was rare, especially when using rotating wood, only the core of it could be used. When finding a tree, people used an axe to cut it down, sawed off the usable part, let it dry and transported it down the mountain, often put it on a raft and carried it downstream. Because rotating wood is not easy to find, there were also cases where people followed a boat to find wood in Binh Thuan province to bring back.

The elders of Phuoc Loc village, Tinh Son commune (Son Tinh) also said that in the past, due to the lack of covers for pressing sugarcane, sugarcane owners hired about seven people with axes, machetes, and ropes to go into the forest in Khanh Hoa province to find wood to turn. Once found, it took several months to transport it back to their hometown to make covers.

The wood for the cover must of course be completely dry. The most difficult part of the cover is to create the “three cover sets”. The “three cover sets” must be compatible in size, and match each other in the rows of teeth (cotton). The cover sets have different sizes, sometimes “6 hands”, sometimes “8 hands”, “10 hands”, the “6 hands” set is too small, squeezing sugarcane slowly, the “10 hands” set is too big, the “8 hands” set is considered the right size, the most popular. After having the rotating wood, the “man making the goods” first calculates the compatibility of the three pieces of wood, then rolls the three pieces of wood into a ball, the upper part with the “cotton” (two rows of teeth) is bigger, the lower part (broken body) is smaller.

Without machinery, people dig a small rectangular hole, build a frame on top, put the wooden block with the shaft attached, and put it on the frame, then one person leans on the frame and uses his feet to turn the wooden block, another person sits and leans on the wood turning tool, and so on, people round from the "flower" part to the "broken body", then to the "cover neck" (rotating shaft). After rounding, people roll the wooden block to the place where they carve to make the "flower", according to the size drawn on the wooden block. With three covers, the outer frame is relatively simple, as long as the wood is hard and compatible with the three covers. On top is a thick piece of wood (called the mouth) with three round holes drilled to put the "cover neck" in, below (called the tub) there is a ditch drilled to let the sugarcane juice flow when pressed, two "main pillars" on both sides have long legs to be buried in the ground, with pins connecting to the "mouth" (above) and the "tub" (below). In addition, some other parts must be created.

Each cover can be used for about 10 - 20 years before it breaks down and needs to be replaced. After a few years of use, each sugarcane pressing season, the cover wears out, and people have to ask a "man running the line" (specialized in adjusting covers) to adjust it. According to French official G. Bauman in the document Sugarcane in Quang Ngai (La Canne à Sugre au Quang Ngai - Bulletin Économique l'Indochine, Annee 1942 - Faceicule IV), in 1942 Quang Ngai had up to 2,000 sugar mills. Each sugar mill had a set of sugarcane covers, so there must have been at least 2,000 sets of sugarcane covers. This also means that there were quite a few "man making goods" and "man running the line". But then war, time, and the advent of industrial sugar mills, made this profession fall into the past.

Article and photos: CAO CHU

RELATED NEWS, ARTICLES:

Source

![[Photo] Students of Binh Minh Primary School enjoy the full moon festival, receiving the joys of childhood](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/3/8cf8abef22fe4471be400a818912cb85)

![[Photo] Prime Minister Pham Minh Chinh chairs meeting to deploy overcoming consequences of storm No. 10](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/3/544f420dcc844463898fcbef46247d16)

![[Photo] Binh Trieu 1 Bridge has been completed, raised by 1.1m, and will open to traffic at the end of November.](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/10/2/a6549e2a3b5848a1ba76a1ded6141fae)

Comment (0)