Garbage was picked up at the upstream of the Mat Son siphon - one of the garbage "hotspots" on the North Canal. Photo: HT

Sadness... North Channel

The North and Main canal systems of the Bai Thuong irrigation system are over 70km long, taking water from the Bai Thuong irrigation dam on the Chu River, flowing through a large residential area, stretching through the districts of Tho Xuan, Thieu Hoa, Dong Son and Thanh Hoa City (the name before the operation of the 2-level local government) managed and operated by Song Chu One Member Co., Ltd. This is an important water supply system, not only serving the irrigation needs of more than 50 thousand hectares of agricultural land of the localities but also providing raw water for the clean water factory, thereby providing domestic water for the large residential area living in the irrigation area of the system, especially the domestic water supply system for many key wards and communes today.

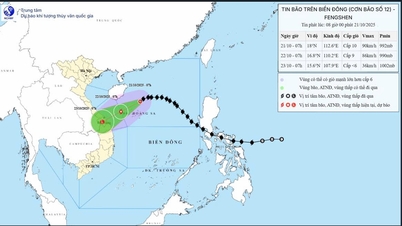

However, the North canal system is also one of the key points for waste. Every year, on the Main canal, the section from Bai Thuong dam to Ban Thach dam at K17+200 (about 17.2 km long), there are hundreds of tons of waste dumped into the canal by a group of people lacking awareness and responsibility, causing sedimentation of the canal, blocking the flow, polluting the water environment, and losing the beauty and safety of irrigation works.

Faced with that situation, the company has researched many ways to limit the situation of littering indiscriminately into rivers and irrigation canals such as: Coordinating propaganda on the loudspeaker system of communes and wards; distributing leaflets in residential areas along canals, socializing contracts with mass organizations to propagate, prevent,... The situation of waste has improved but is still a constant concern. Along with promoting propaganda and mobilization to raise people's awareness, to ensure enough water for agricultural production as well as protect the quality of water sources and the living environment around the river, the company has synchronously deployed many solutions.

Since 2012, Song Chu Company has proactively coordinated and worked with Ban Thach Hydropower Plant at K17+200 on the Main Canal to retain the amount of waste flowing down from above and organize on-site salvage. The company plans to dredge and clear canal sections that have been silted by waste and alluvial soil to ensure smooth flow for production. Currently, the direct salvage and treatment of waste on canals and ditches under the company's management is mainly undertaken by groups and clusters of irrigation workers.

"Manual salvage makes it very difficult for workers to come into direct contact with toxic and polluted waste... but only reduces the amount of waste without thoroughly treating the root of the problem. The waste that is not salvaged will settle in the canals and ditches, causing sedimentation and obstructing the flow. On the other hand, the cost of salvaging, treating and transporting waste every year is very high. If this continues, in the long run, it will affect the funding source for other maintenance and repair items. That is something that the company's management board has been very concerned about over the years" - Chairman of the Board of Members of Song Chu LLC Le Van Thuy shared.

"Blossoming" initiatives from the "captain"

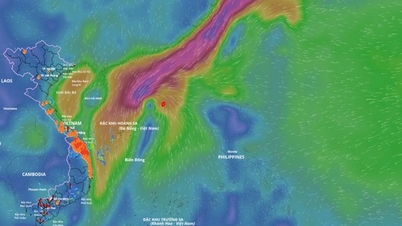

The problem of waste poses an increasingly urgent need, the awareness that urges action is also the "opportunity" for initiatives to flourish. With enthusiasm, responsibility, solid professional knowledge and extensive experience accumulated over decades of working in the industry, Chairman of the Board of Members of Song Chu LLC Le Van Thuy has researched, installed and put into operation the automatic waste collection system upstream of Mat Son siphon - one of the "hot spots" of waste on the North Canal. "Installing a waste system is necessary, bringing many practical benefits. However, designing and installing a completely new system will be very expensive, the company does not have the funds to do it" - Mr. Thuy said.

Do not let difficulties hinder creativity, if you cannot innovate, then research and find solutions to renovate and take advantage of existing raw materials to save costs. Mr. Thuy said: "In fact, at that time, through review and monitoring, we found that the Xom Moi pumping station (under the Nong Cong Region III Flood Control Project) was invested quite well, with an electric garbage collection system. However, because the pumping station is located in the middle of a field, there is no residential area passing through, the amount of garbage collected each time is very small, insignificant and because it is a pumping station, this system rarely has to operate, even some years it does not have to operate".

Studying the drawings and operating methods of the garbage collection system of the Xom Moi pumping station, Mr. Thuy came up with the idea of applying and renovating it into an automatic garbage collection system installed upstream of the Mat Son siphon on the Bac canal system. Mr. Thuy added: "The installation location of the system must ensure the safety of the canal, have few people passing by, and be convenient for the collection and transportation of garbage and be attached to the regulatory works. On the other hand, when installing and operating the system, the surrounding environment must be ensured because the amount of garbage collected must be gathered and wait for treatment." Combining the conditions, Mr. Thuy chose the installation location of the system upstream of the Mat Son siphon (Hac Thanh ward).

To save on installation costs, Mr. Thuy had the idea of utilizing steel rails (previously used to make electric poles, now replaced by concrete poles), steel plates and shaped steel available in the company's warehouse and some locations of the fading slots, upstream work platforms of the unused water intakes to make the frame system and operating platform. Along with that, mobilizing a part of the company's skilled workers to carry out some simple items such as cutting and welding the frame system, installing the crane system, trash screens... According to estimates, if this automatic trash collection system is completely renewed, the cost will fluctuate between 2 and 2.5 billion VND. However, thanks to the idea of taking advantage of renovation, applying the actual situation, taking advantage of available factors, nearly 2 billion VND was saved.

After more than 3 years of being put into management and operation, the automatic garbage collection system at the upstream of Mat Son siphon on the North canal system, renovated and installed by Mr. Thuy, has been operating well and showing clear effectiveness. From the place where irrigation workers always had to strain themselves and try their best to "fight" with the amount of garbage dumped into Mat Son siphon every day, now, with the effective "assistance" of the automatic garbage collection system, workers only need to press the button to operate the system to collect garbage and dump it into the garbage truck; that work is less arduous, hard, and toxic. The amount of garbage from upstream is gathered at one point, convenient for thorough collection work. The collected garbage will be collected into garbage trucks and transported by the environmental company to the garbage treatment point according to regulations. The amount of garbage collected is quite thorough, so it rarely causes sedimentation of the canal bed, less frequent dredging is needed, saving the company billions of dong.

Ms. Ngo Thi Minh Hoa (34 years old, Loc Giang cluster, Thanh Hoa City Irrigation Branch) confided: “Loc Giang cluster has 2 “hot spots” of waste that for many years, the company and branch leaders have always paid attention to, increased the deployment of monitoring forces, and continuously “patrolled the canal”, which are: Mat Son siphon, railway siphon. On average, every day, the irrigation workers of Loc Giang cluster collect about 16 garbage trucks, each truck has about 0.7 cubic meters of garbage. The amount of garbage floating here is huge, just picking up the garbage in front, you can see the garbage behind, human strength is not enough. Not to mention the days when we have to deal with dead animals floating in, the smell is terrible, and we feel sick after doing it. Since the automatic garbage collection system was put into operation, we irrigation workers have been “supported” a lot. Everyone is happy and excited”.

The initiative of the Chairman of the Board of Members of Song Chu LLC, Le Van Thuy, not only contributes to reducing the "burden" of annual costs for waste collection, dredging canals, improving work efficiency, contributing to clearing water sources for irrigation for agricultural production, ensuring water quality, environmental sanitation, safety for workers and irrigation works. Above all, the effectiveness of the initiative and the willingness to innovate, not afraid of difficulties, interested in and promoting the application of science and technology, digital transformation, initiates a new way of thinking in management and operation at Song Chu LLC. “Up to now, the effectiveness of the automatic garbage collection system at the upstream of Mat Son siphon is clear. The most regrettable thing is that up to now, we have not been able to replicate this model due to limited funding. We are still trying and making efforts to find “sources” to encourage and promote scientific research, experience initiatives, application of science and technology, digital transformation, and improve the company's operational efficiency,” Mr. Thuy confided.

Thuy Duong - Huong Thao

Source: https://baothanhhoa.vn/sang-kien-hay-cho-nguon-nuoc-sach-254949.htm

![[Photo] Chairman of the Hungarian Parliament visits President Ho Chi Minh's Mausoleum](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760941009023_ndo_br_hungary-jpg.webp)

![[Photo] Prime Minister Pham Minh Chinh meets with Speaker of the Hungarian National Assembly Kover Laszlo](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760970413415_dsc-8111-jpg.webp)

![[Photo] National Assembly Chairman Tran Thanh Man holds talks with Hungarian National Assembly Chairman Kover Laszlo](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760952711347_ndo_br_bnd-1603-jpg.webp)

![[Photo] Solemn opening of the 10th Session, 15th National Assembly](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760937111622_ndo_br_1-202-jpg.webp)

Comment (0)