Although SMIC has successfully produced 5nm wafers with DUV machines, mass production has been difficult due to high costs and low yields. These obstacles have also negatively affected Huawei and prevented the company from surpassing 7nm technology. But things are looking up as SMIC is gradually moving towards EUV machines made in China.

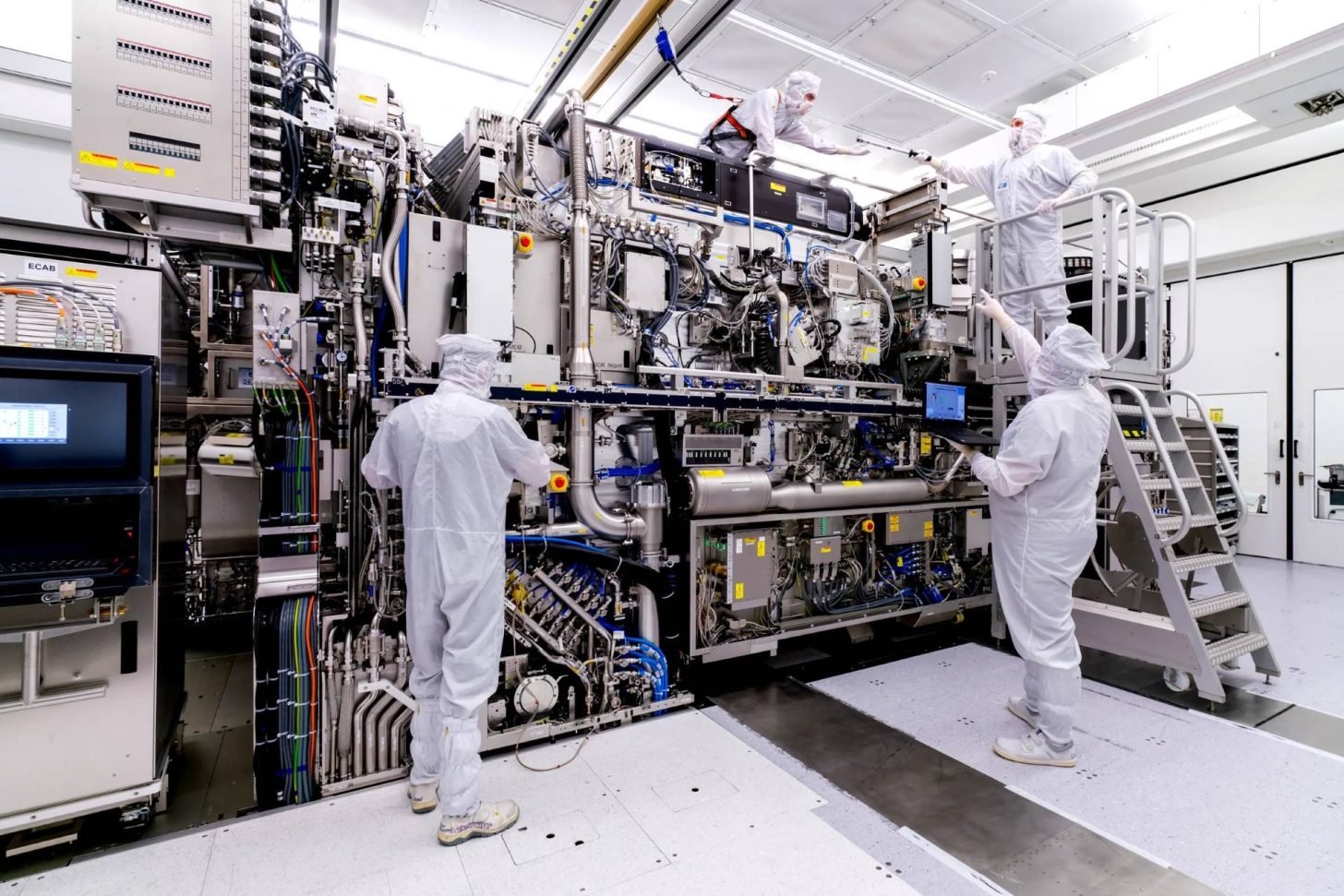

ASML's EUV machine is the size of a bus

According to the latest report, SMIC is expected to start trial production of customized EUV machines in the third quarter of 2025. These machines will use laser-induced discharge plasma (LDP) technology, different from ASML's laser-induced plasma (LPP).

Mass production of China’s own EUV machines could begin in 2026, with simpler and more power-efficient designs, which would help China reduce its dependence on companies affected by the US ban and give it a competitive advantage.

EUV machine “Made in China” revealed for the first time

Images shared by social media accounts recently show a new system being tested at Huawei's Dongguan facility. A research team from Harbin Provincial Innovation has developed an electric discharge plasma technique that can produce EUV lights with a wavelength of 13.5nm, meeting market demand.

Leaked image is said to be of Chinese EUV machine preparing for testing

The process involves vaporizing tin between electrodes and converting it into plasma through a high-voltage discharge, with electron-ion collisions creating the required wavelength. Compared to ASML's LPP, the LDP technology is said to have a simpler, more compact design, consume less power and have lower manufacturing costs.

Before these trials began, SMIC and China were still relying on older DUV machines, which used 248nm and 193nm wavelengths, which were far inferior to EUV's 13.5nm wavelength. Because of this limitation, SMIC needed to achieve multiple patterning steps to achieve advanced nodes, which not only increased wafer production costs but also extended production times, leading to huge bills. As a result, SMIC's 5nm chips would be 50% more expensive than TSMC's chips when produced using the same lithography technology.

Currently, Huawei is limited to developing its own Kirin chips on the 7nm process, while the company can only make minor adjustments to improve the capabilities of new SoCs. If China succeeds in developing advanced EUV machines, Huawei could close the gap with Qualcomm and Apple and bring much-needed competition to the semiconductor industry.

Source: https://thanhnien.vn/trung-quoc-san-sang-cho-may-in-thach-ban-euv-cay-nha-la-vuon-185250310223353963.htm

![[Photo] The road connecting Dong Nai with Ho Chi Minh City is still unfinished after 5 years of construction.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762241675985_ndo_br_dji-20251104104418-0635-d-resize-1295-jpg.webp)

![[Photo] Ho Chi Minh City Youth Take Action for a Cleaner Environment](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762233574890_550816358-1108586934787014-6430522970717297480-n-1-jpg.webp)

![[Photo] Panorama of the Patriotic Emulation Congress of Nhan Dan Newspaper for the period 2025-2030](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762252775462_ndo_br_dhthiduayeuncbaond-6125-jpg.webp)

![[Photo] Ca Mau "struggling" to cope with the highest tide of the year, forecast to exceed alert level 3](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762235371445_ndo_br_trieu-cuong-2-6486-jpg.webp)

Comment (0)