The garbage collection area of Yen Dung district, Bac Giang (old) was once heavily polluted because it was flooded with tens of thousands of tons of leftover garbage, had a strong stench, and was swarmed with flies like a broken beehive.

Now that scene is gone.

Instead, it is a smokeless, noiseless factory, and few people think that inside it is a cycle of turning trash into "black gold".

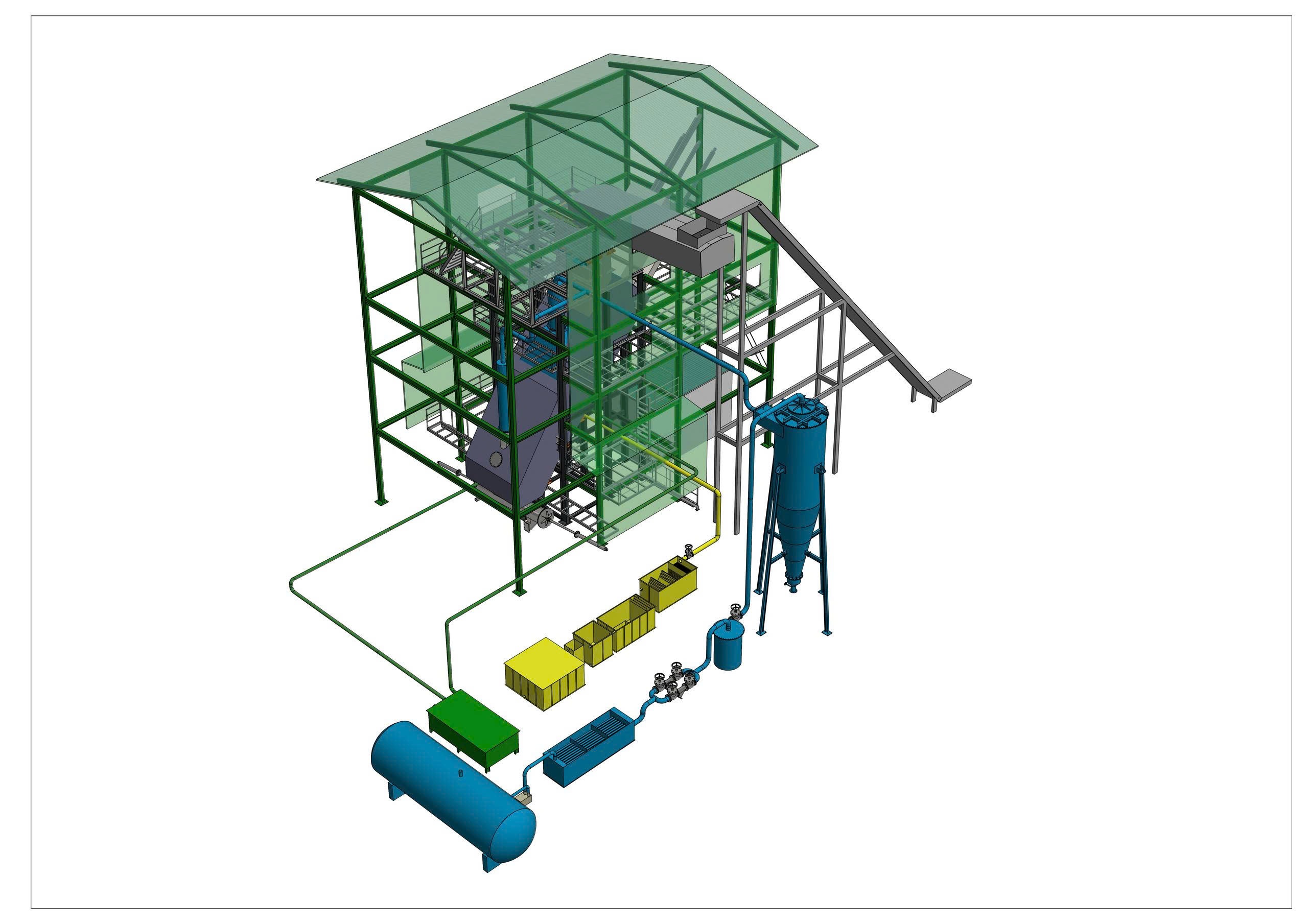

The waste is carried up the conveyor to the top position of the thermochemical tower.

This transformation took place after more than 6 months of operating the “3 no” waste treatment system: no burning, no burying, no emissions, researched, designed and deployed by a group of Vietnamese engineers. This is also the first zero-emission waste treatment system in Vietnam.

The core of the system is the variable pressure catalytic thermal decomposition technology. Instead of burning waste at high temperatures above 950 degrees Celsius like traditional incinerators (which emit many toxic gases such as dioxin and furan), this technology uses much lower temperatures (280–320°C) in an anaerobic environment (without oxygen) to “break” the bonds in the waste, helping the waste decompose slowly without burning.

The core of the system is variable pressure catalytic decomposition technology.

Because it does not burn, it does not produce smoke, fine dust or toxic gases. This is also a treatment technology that does not require waste sorting at the source, an important breakthrough in the context that more than 90% of household waste in Vietnam is still mixed waste.

Each day, a system can process 60–160 tons of waste, enough to serve a commune cluster or a small urban area without the need to build a landfill.

The waste treatment cycle is divided into 6 closed operating zones:

1. Reception and pre-treatment: Input waste is stripped of inert materials and moisture is balanced.

2. Variable pressure catalytic thermal digestion furnace: Here, waste is put into an anaerobic thermal reaction combined with catalyst.

3. Recovery and treatment of biogas and bio-oil: Syngas and bio-oil are filtered, separated and cleaned. The gas and oil are reheated to the reactor without using fossil fuels.

4. Biochar recovery and cooling: The waste after reaction forms biochar, which is cooled in a sealed container to ensure safety and quality.

5. Condensate treatment: Separate clean water from the reaction process and reuse it.

6. Monitoring control cluster: Automate the entire system, real-time control.

The special thing is that the energy generated from the waste will be recycled to maintain heat for the reactor and can be sold to other fields when there is surplus.

Waste treatment system operator.

Clean gas (syngas) is used to maintain heat for the treatment furnace itself. Bio-oil can be supplied to the boiler or used in industry. Bio-char is used as fuel for burning and improving soil. Clean water is recovered to meet standards to serve the system's operations.

All output products are independently tested at the Institute of Energy and Environmental Science and Technology - Vietnam Academy of Science and Technology. The results show that they meet industrial standards and are not harmful to the environment or humans.

With its flexible modular structure, this technology can be replicated in any province or city, from mountainous areas to urban areas, without the need for an upstream waste sorting system. Each module can operate independently, is easy to maintain, saves space and saves on processing costs.

Concerns from the mountains of garbage dumps polluting the whole region

To have this advanced waste treatment system is a long time of "eating and sleeping" with waste by a group of Vietnamese engineers with various majors, but sharing the same concern about the country's environmental problems.

Waste treatment is a challenging issue.

Engineer Pham Quoc Hung - a member of the zero-emission waste treatment system research team, recalls business trips from north to south 10 years ago, which led to the team's decision to delve into waste treatment research.

“Everywhere we went, the landfills were piled up like mountains and polluted. I went to Nam Son ( Hanoi ), then Dinh Vu (Hai Phong), and everywhere was overloaded. On the news at that time, it was not difficult to see information about people setting up tents to block vehicles because they could not stand the stench,” engineer Hung recalled.

The group approached the waste treatment field with a clear goal: there had to be a radical solution.

During the research, they realized that garbage is not just a waste, but also a form of fuel. Some types of household waste have energy equivalent to Quang Ninh's coal dust 6, reaching 3,800–4,200 kcal/kg.

“We realized that garbage is not just an environmental problem. Garbage is energy. Garbage is an opportunity. If we treat garbage thoroughly, Vietnam will not only solve pollution, but also touch the energy problem,” engineer Hung analyzed.

Billion-dollar import system "helpless" with Vietnamese garbage

A "scientific council" of four members was established, each with a different expertise: design - automation, equipment, technology, petrochemicals - energy to find the solution.

According to engineer Hung, the biggest difficulty for Vietnam’s waste is not only technology, but the technology must be suitable for the actual conditions of waste in Vietnam. Developed countries have a system of sorting waste from the source, helping to make the waste clean, uniform, and easy to handle.

In Vietnam, household waste is a mixture of everything from food, nylon bags to bricks, construction waste, and even hazardous waste. Low calorific value, high humidity, many impurities, easily causing blockages and extreme reactions in the furnace. If foreign technology is applied directly, it will be difficult to operate effectively, often causing furnace blockages.

Next question: How to deal with garbage?

Referring to a series of models in the world such as: American plasma, German fluidized bed combustion, Japanese high temperature treatment, the group of engineers were overwhelmed by modern technology. But they also quickly realized the truth that investing in them was too expensive, the processing cost was even more expensive.

The American module was put into testing by the team.

“Waste treatment fees in the US can cost up to $100/ton. Meanwhile, in Vietnam, the average cost for waste treatment is usually only $15-20/ton. If foreign machinery is used, the operating costs alone will kill the business right from the start.

“If the problem of unsorted waste cannot be solved and the cost cannot be affordable domestically, then all solutions will only remain on paper,” engineer Hung analyzed.

Through the research process, the group created its own prototype waste treatment module. However, because it did not really believe in its ability to “invent itself”, the group invested billions of dong in a module using American technology for parallel testing. In fact, initially, most of the resources and expectations were for this foreign technology.

“We thought that foreign countries were more developed, certainly better, so we prioritized American technology. At that time, we didn’t really believe in ourselves, didn’t really believe in Vietnamese intelligence. But when we got into reality, we realized that American technology was modern and good, but it wasn’t suitable for Vietnamese waste,” engineer Hung shared.

The system was put into operation to test waste treatment in Yen Dung (old) from the end of 2024, but after only a few months, local waste quickly showed its complexity and "difficulty".

No classification, high humidity, many impurities, low calorific value. Machines are constantly clogged, and the reaction in the furnace is unstable.

“We realize that there are problems of the Vietnamese people that should be solved by the Vietnamese people. Let the Vietnamese people research solutions for the Vietnamese people,” said engineer Hung.

Eat and sleep with trash to research, discuss each bolt

Having failed with plan A, which had involved almost all of their resources, the research team decided to "start over" with their brainchild.

3D model of zero-emission waste treatment system.

Engineer Bui Quoc Dung - Head of the technology research team remembers clearly the period of many months when the members ate and slept in temporary housing at the landfill, to research, discuss and experiment.

“When we first arrived here, the garbage was piled up 7-8 meters high, the leachate was black, and flies swarmed the entire area. In general, it was terrible. At that time, I remember having sticky rice for breakfast but I couldn’t sit down and eat it, I had to walk while eating so the flies wouldn’t get on it.

Engineer Bui Quoc Dung - Head of technology research team.

But the whole group is determined to put all their efforts into gradually renovating, living and eating with the workers," engineer Dung shared.

To improve and perfect their waste treatment system, the research team faces many big problems to solve.

The most difficult problem is how to handle mixed waste. This is the big question that has caused many non-incineration waste treatment technologies to fail when applied in Vietnam.

The system developed by the group is a technology to convert waste using a thermal environment - called thermochemistry for short. The core is to use chemical reactions in a thermal environment to break down organic bonds in waste. In a mass of waste, there are many complex components, some of which are very difficult to separate, so it is necessary to create reaction conditions that can decompose to the maximum.

The goal is to create three distinct phases: solid – liquid – gas. Solid is coal, liquid is oil, gas is gas. To do that, the system must operate in a strict cycle, through many consecutive processing steps.

First, how to put the waste into the reaction chamber. When the waste enters the reaction chamber, it will create many products: gas, steam, oil, and coal. The group must find a way to process all four of these substances to create usable products that serve human life well.

The research process begins by “breaking down” each large problem.

They divided the specific issues: How to pre-select the input waste, how to control the humidity, what materials can withstand heat and corrosion, how the air and oil flow in the furnace operates, where the solids go, where the liquids and gases escape, how to make it both airtight and easy to maintain...

Each question is divided into many small parts, related to chemistry, mechanics, hydraulics, materials, energy, thermodynamics, automation...

The products generated are recycled as fuel for the treatment system.

The group started over as students, searching for documents, redrawing from the first hand sketch, simulating every detail of the reaction chamber, redesigning the paths of gas, coal, water, and oil.

Every issue raised is thoroughly debated. Those with new ideas must defend their views, and others have the right to question them to the end. There are initiatives that are discussed for weeks but are eventually rejected because they are not feasible.

“There was a period when we had meetings as soon as we opened our eyes. We constantly debated each other to finalize the optimal solution for every small detail such as: bolts, gaskets, seals, smoothness, slope of the furnace…”, said engineer Dung.

This expert calls it a “combined machine of hundreds of innovations”, formed from many technical problems and life experiences.

A typical example is the problem of handling syngas. The gas produced from waste has properties different from commercial gas. There is no stove on the market that can burn this gas, so they had to try hundreds of nozzles to find the right gas mix. Similar to bio-oil, the team had to design their own furnace to avoid smoke and maximize energy.

Typical Vietnamese household waste also corrodes equipment faster than normal because it contains acid, fish sauce, salt, and domestic wastewater. The research team uses heat-resistant anti-corrosion paint and combines multiple layers of materials to extend its lifespan.

There are seemingly simple problems, such as removing coal from a closed furnace, which become difficult problems and are solved almost in the end. Because in a temperature environment of approximately 300 degrees Celsius, no type of gasket is suitable for long-term use.

“In principle, the furnace must be sealed. It is easy to take liquid and gaseous materials, but it is not easy to take solid materials out of a closed furnace. The system must have thrust, be anti-clogging, be smooth, and finally, it must be sealed when opening and closing. This is a heat zone, so no gasket or seal can withstand such high temperatures and be durable,” engineer Dung analyzed.

The structure is inspired by a jute gun to bring coal out.

After a week of thinking, this engineer found the solution from the gun that shot jute balls when he was a child. This type of gun had to be completely sealed to shoot. He called it the “charcoal gun innovation” with a hydraulic piston system instead of the bamboo stick in his childhood toy.

During the testing process, the team had to continuously bring samples of output products, from gas, coal, water to oil, for testing at the Institute of Chemistry and the Institute of Environment - Energy.

Coal alone was tested more than ten times, gas several dozen times, and wastewater had hundreds of indicators. Each time the test failed, the whole group had to go back and make adjustments.

“We have a thick stack of inspection records. When one target is met, another is not. We have to meet again, make theoretical adjustments, then go out to experiment, then go back to testing,” said engineer Dung. “It’s impossible to count how many loops like that.”

Testing stops when all four output products meet group standards.

When garbage is a resource

To date, the team has completed three different capacity modules: 40–60 tons, 60–80 tons, and 100–120 tons/day. The largest module alone can be coupled into a 1,000-ton processing system.

After a period of operation, the factory converts domestic and industrial solid waste into stable operating energy with a capacity of 120-150 tons/day.

A smokeless, wastewater-free, odorless, ash-free garbage factory, once considered impossible, is now a reality.

“We aim for a model of waste treatment at the source in each commune or cluster of communes so that it does not have to be transported far away, both saving costs and protecting the environment.

If we just concentrate 500-600 tons/day into a large factory, some localities will have to transport the garbage nearly 100km, and in mountainous areas it will be even more difficult, sometimes the transportation cost is even higher than the waste treatment cost for the factory," engineer Hung analyzed.

Not stopping at household and industrial waste, the research team said this technology can be adjusted in some parts of the system to handle dead animals due to epidemics such as African swine fever, bird flu...

Large outbreaks can force each locality to destroy hundreds of tons of livestock and poultry by traditional burial methods. This not only wastes biological resources, but also poses the risk of soil and groundwater pollution, and does not exclude the situation of illegal dumping of carcasses, which causes biosecurity risks.

“In the past, when talking about waste treatment, people only thought of burning or burying it. But now, waste is no longer something to be thrown away, but a resource that creates economic value,” engineer Pham Quoc Hung proudly shared, looking at the operating line.

Photo: Minh Nhat, Bao Ngoc

Video: Doan Thuy

Source: https://dantri.com.vn/khoa-hoc/an-ngu-voi-rac-ky-su-viet-tao-he-thong-xu-ly-rac-khong-phat-thai-dau-tien-20250805152731296.htm

![[Photo] Closing of the 13th Conference of the 13th Party Central Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/08/1759893763535_ndo_br_a3-bnd-2504-jpg.webp)

Comment (0)