New leverage for green growth

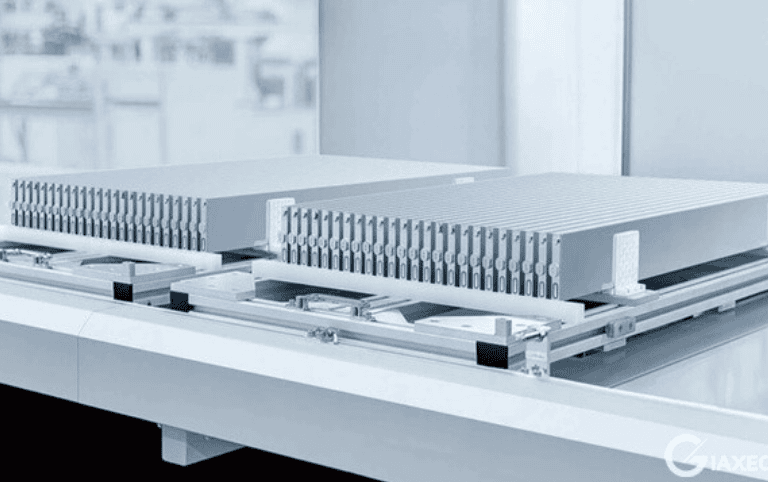

Vietnam's ambition to transition to clean energy is increasingly evident in national policies. According to the Power Development Plan VIII, by 2030, renewable energy will account for over 39% of total electricity production; simultaneously, Prime Minister's Decision 876/QD-TTg aims for 100% of road transport vehicles to use electricity or green energy by 2050. These goals create momentum for growth in a key industry: the production and export of lithium batteries.

According to a report by IMARC Group, the lithium-ion battery market in Vietnam is projected to achieve a compound annual growth rate (CAGR) of 10.1% between 2025 and 2033, driven by booming demand from electric vehicles and energy storage systems. Responding to this trend, numerous large-scale battery manufacturing projects are being implemented across the country.

Notably, VinES, a subsidiary of Vingroup, is building a battery factory in the Vung Ang Economic Zone (Ha Tinh province), with a phase 1 capacity of 5 GWh/year and a total investment of over 6,000 billion VND. In Bac Giang , the Sunwoda Group (China) is also investing in a lithium battery factory worth over 275 million USD. Meanwhile, Samsung SDI has been operating a battery production complex in Thai Nguyen, supplying the global electronics and electric vehicle industries.

Along with FDI investment, Vietnam is developing battery industrial clusters in the northern region, such as Ha Tinh , Bac Giang, Thai Nguyen, and Hai Phong. This model is expected to replicate the success of Shandong (China), where the integrated lithium battery supply chain spans from mining and manufacturing to final assembly, with a total investment of over $14 billion.

In particular, Resolution No. 68-NQ/TW has created a favorable legal framework for the development of clean industries and logistics by emphasizing the role of the private sector, expanding industrial parks, and upgrading infrastructure. As a result, Vietnam is gradually building the foundation to become a strategic manufacturing destination in the global battery value chain.

However, to achieve the goal of becoming a leader, Vietnam's lithium battery industry needs not only capital, technology, and human resources, but also another crucial element: a specialized logistics system capable of handling sensitive and hazardous goods like lithium batteries.

Upgrading logistics to capitalize on export growth.

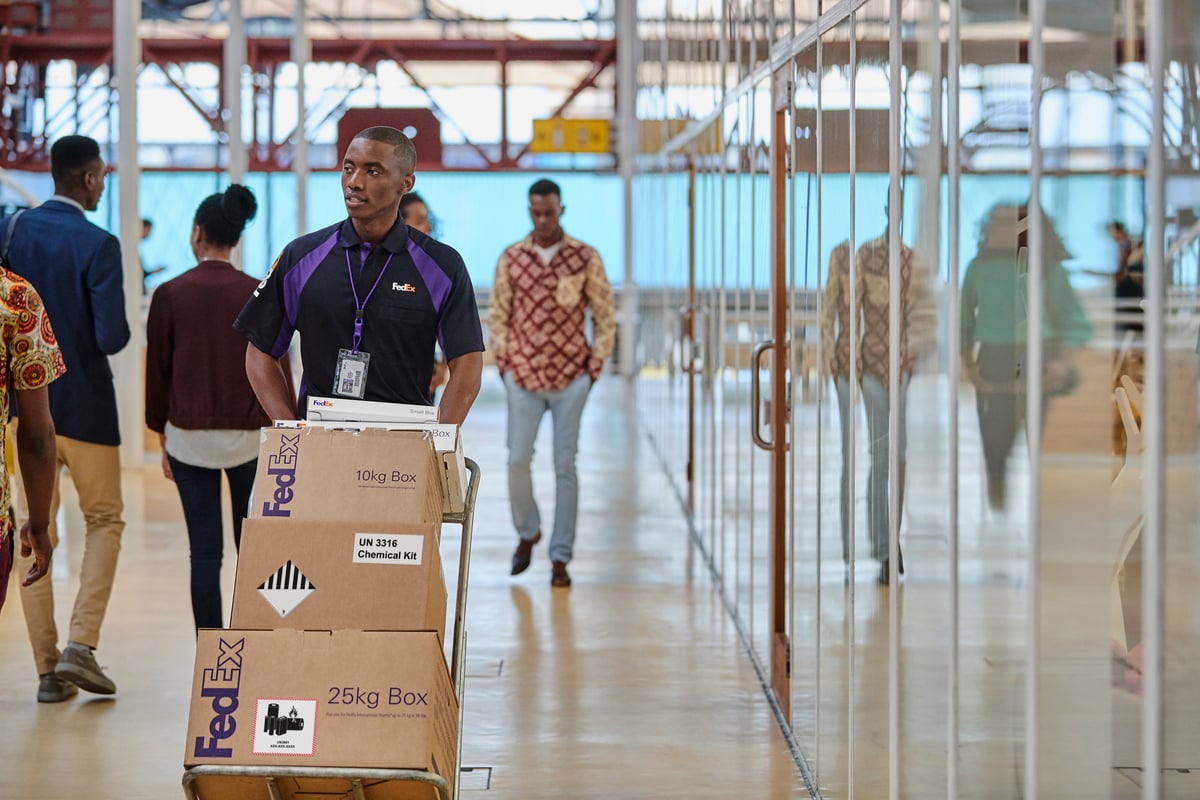

Ms. Ee-Hui Tan, Operations Director of FedEx Vietnam and Cambodia, stated that lithium batteries are classified as Dangerous Goods (DG) due to their flammable and explosive nature if not handled properly. Therefore, transporting this type of cargo must strictly adhere to international regulations such as IATA (International Air Transport Association) and ICAO (International Civil Aviation Organization). From packaging that meets United Nations (UN) standards and identification labeling to shipping documentation, every process requires absolute accuracy and safety.

In Vietnam, the logistics ecosystem is gradually adapting to new standards. International companies such as FedEx, DHL Express, and specialized international freight forwarders and carriers like Dimerco now offer comprehensive logistics solutions for lithium battery shipments.

For example, FedEx ships millions of battery shipments annually, offering UN-certified packaging solutions, real-time tracking tools, and specialized DG (Direct Load) shipping services. Meanwhile, DHL Express only accepts lithium batteries for shipment from customers who have been approved as eligible DG, ensuring safety according to IATA standards.

Additionally, in Vietnam, domestic logistics companies such as IPO Logistics, HDG Logistics, and Ai Logistics also provide transportation and customs clearance services for lithium batteries. These companies assist with HS Code classification, prepare UN38.3 certificates, handle customs clearance procedures, and ensure safe domestic transportation.

With ASEAN currently a hotbed of investment in the battery supply chain, logistics will be a decisive factor in the ability to "catch up and surpass." To compete, according to Ms. Ee-Hui Tan, Vietnam needs to accelerate the development of specialized logistics, from training personnel to handle gross merchandise (DG), applying technology to track shipping documents, to simplifying customs procedures. More importantly, partially localizing the logistics process will help reduce costs, increase delivery speed, and enhance proactiveness in the global supply chain.

Vietnam currently possesses the favorable conditions – "the right time, the right place, and the right people" – to become the lithium battery manufacturing hub of Southeast Asia. However, to transform this potential into reality, economic experts believe that logistics needs to be viewed as a strategic pillar on par with technology, investment capital, and policy. When the logistics ecosystem is strong enough, Vietnam will not only export batteries but also export confidence within a global value chain that is betting on clean energy.

Source: https://doanhnghiepvn.vn/cong-nghe/logistics-manh-ghep-chien-luoc-trong-chuoi-pin-lithium-viet-nam/20250722081649074

![[Image] Close-up of the newly discovered "sacred road" at My Son Sanctuary](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F13%2F1765587881240_ndo_br_ms5-jpg.webp&w=3840&q=75)

Comment (0)