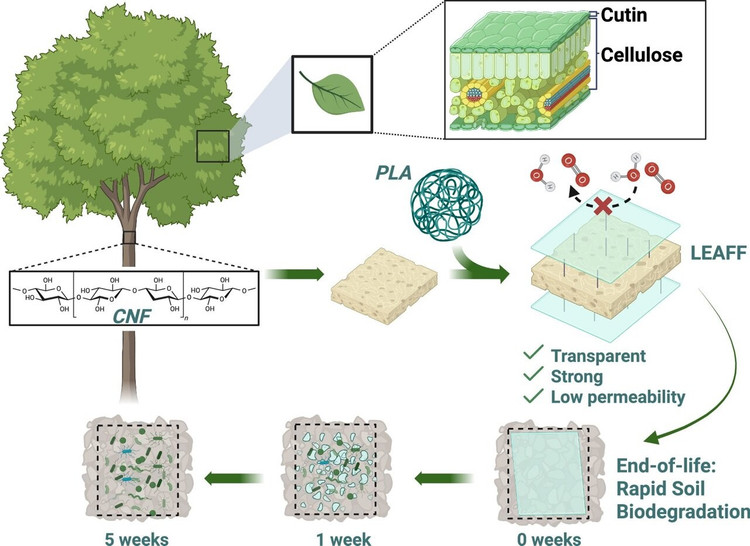

A group of scientists at Washington University in St. Louis (USA) has just announced a new bioplastic material called LEAFF - short for "Advanced Multilayer Bio-leaf". This material is made with a structure simulating tree leaves, in which the core layer is cellulose nanofibers, surrounded on both sides by PLA plastic (polylactic acid).

This three-layer structure increases tensile strength, toughness, water resistance and printability, while allowing the material to biodegrade naturally without the need for industrial composting equipment.

LEAFF has a much better tensile strength than common plastic materials such as polyethylene (PE) or polypropylene (PP). In mechanical tests, LEAFF film showed twice the strength of pure PLA and far exceeded other commercial bioplastics. In addition, this material is also moisture resistant, gas-proof, maintains mechanical stability for many days in the environment and does not deform when exposed to water.

LEAFF stands out for its ability to biodegrade in the natural environment. Conventional PLA plastics can only degrade rapidly under industrial composting conditions with high temperatures and controlled humidity. However, when integrated with a cellulose nanofiber core and redesigned with a multilayer bio-based structure, LEAFF begins to degrade when exposed to microorganisms in soil or water without requiring special treatment conditions. After about two weeks, the material can significantly reduce its mass in bacteria-rich environments such as lake water or moist soil.

The work also expands the possibilities for material production by testing different biomass sources. The team used carbon dioxide, corn waste, lignin (from wood), and food waste to synthesize biopolymers, through the action of the bacterium Pseudomonas putida. This bacterium is capable of absorbing complex organic compounds and converting them into polyhydroxyalkanoate (PHA) or polyhydroxybutyrate (PHB), two types of bioplastics with great potential for biodegradability and biosafety.

In addition to PLA, LEAFF was also tested in combination with PHB to further improve the material's mechanical properties. When combined with a cellulose core, the three-layer PHB film produced a material with greater flexibility while still retaining effective degradability. Notably, these variants could still be produced using conventional film extrusion processes used in the packaging industry.

Another advantage of LEAFF is the ability to print information directly onto the surface using bio-inks without the need for a coating. This property is particularly suitable for food packaging, labeling or medical packaging applications where both antibacterial and environmental friendliness are required.

LEAFF is currently considered one of the latest technical solutions to replace traditional plastic materials in applications that require high durability but still ensure biodegradability under normal conditions.

Source: https://khoahocdoisong.vn/my-phat-trien-loai-nhua-sinh-hoc-moi-than-thien-voi-moi-truong-post2149043234.html

Comment (0)