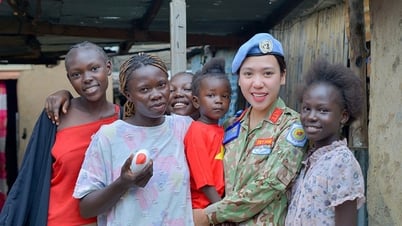

Blood bags with additional labels over the original labels - Photo: Provided by readers

These blood bags, according to the reflection, were labeled with screening and codes from upper-level hospitals. However, when they arrived at Can Tho Hematology and Blood Transfusion Hospital, they were labeled with different labels.

This is not in accordance with the regulations of the Ministry of Health and the circulars of ministries and branches guiding the labeling of goods, especially for sensitive product groups such as drugs, cosmetics, functional foods, blood products, etc.

"Because the hospital does not screen or test, but prints and pastes labels on top of the labels of the suppliers. When the blood bags reach the user unit and are supplied to patients, if there is an incident, the traceability of the origin must of course be based on the product label and code of the manufacturing unit," the complaint said.

Talking to us about this reflection, the leader of Can Tho Hematology and Blood Transfusion Hospital said that the issue of receiving blood from upper-level units has been reported to the Department of Health .

Due to the COVID-19 pandemic from 2021 to present, the blood reserves of the National Institute of Hematology and Blood Transfusion and hospitals in Ho Chi Minh City are in some places lacking blood products, while others have excess. Therefore, upper-level units coordinate blood to support each other.

Up to now, there have been periods when the blood supply is limited and cannot meet the needs of hospitals, so Can Tho Hematology and Blood Transfusion Hospital still has to receive blood products from upper-level units to provide to medical examination and treatment facilities in the area.

For each blood supply unit, the hospital must create a unique code and a separate label. This is to easily and quickly trace the origin of the blood product and to distinguish the identity of the blood product provided by the hospital in case of emergency.

The process at Can Tho Hematology and Blood Transfusion Hospital is: receiving blood products to the hospital's warehouse (with complete labels from the supplier); preliminary inspection of the quality of the blood bag (sensory perception of color, integrity of the blood bag); next is recoding the blood bags of each supplier and using a secondary label to stick on the blood bag.

According to the leader of Can Tho Hematology and Blood Transfusion Hospital, the additional labeling still ensures full traceability and standards for blood bag labels, because the code of the manufacturing unit is still present.

Explaining the reason for the additional label overlapping the label of the manufacturing unit, the hospital said that due to the characteristics of blood bags, labels are only allowed to be placed on a certain area (the remaining areas are for gas exchange for living red blood cells), so the additional label must be placed over some information of the original label.

Through feedback, the hospital will take note and have researched to adjust the size of the secondary label to be smaller and stick it in a position that does not overlap with the main label of the manufacturing facility, to ensure the classification of blood and preparations provided according to each specific unit.

Source: https://tuoitre.vn/nhan-tui-mau-cung-cap-lai-dan-nhan-phu-de-len-nhan-goc-co-dung-khong-20250527163156324.htm

![[Maritime News] More than 80% of global container shipping capacity is in the hands of MSC and major shipping alliances](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/7/16/6b4d586c984b4cbf8c5680352b9eaeb0)

Comment (0)