In October 2025, Omoda & Jaecoo Vietnam Automobile Factory officially entered the large-scale construction phase, marking an important step in the journey to realize the strategy of increasing the localization rate in Vietnam. Notably, all legal documents have been completed in full, on schedule as committed by the enterprise a year ago.

Real investment commitment

Since its launch in the Vietnamese market, Omoda & Jaecoo Vietnam has not only introduced high-tech product lines with trendy designs, equipped with international safety technology , but also affirmed its long-term investment strategy, including domestic production. Within just one year since then, Omoda & Jaecoo Vietnam has proven that the promise is not just on paper, but is becoming a reality with a methodical and drastic implementation progress.

The completion of all legal documents for the Omoda & Jaecoo car manufacturing factory project in Hung Yen (formerly Thai Binh ) is a testament to the seriousness and professionalism in investment preparation. With the support of functional agencies and local authorities, Omoda & Jaecoo Vietnam has ensured transparency, compliance with the law and environmental protection in all stages of implementation.

Speed up construction

Immediately after completing the legal procedures, the project has moved to the accelerated construction phase. Currently, the foundation items for the assembly workshop, welding - painting - inspection are being deployed simultaneously. The internal traffic system, water treatment, administrative building and logistics warehouse are also being constructed on schedule, closely monitored by the international project management team.

It is expected that by the first quarter of 2026, the factory will complete the rough construction and install modern automated production lines imported from Europe and China. The goal is that by the end of 2026, the first “Made in Vietnam” cars under the Omoda & Jaecoo brands will officially be released.

Production infrastructure

In the first phase, Omoda & Jaecoo Vietnam factory was built on a total area of over 380,000 m², with a total investment of up to VND 8,125 billion and a designed capacity of 120,000 vehicles/year. This is one of the large-scale automobile manufacturing projects in Vietnam today, oriented not only to serve the domestic market but also to export in the region. In the future, this complex will continue to expand both in terms of area and production capacity, to meet increasing demand and improve competitiveness in the global market.

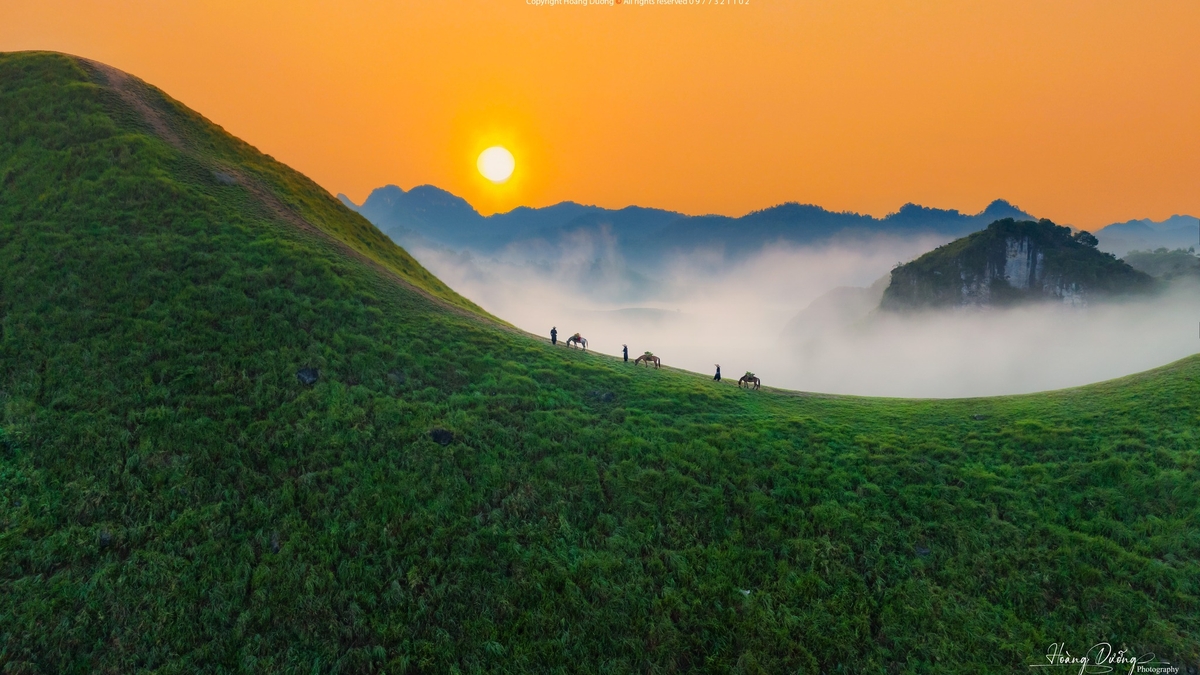

In particular, the factory is planned and designed according to the “Green Factory – Smart Factory” model, applying a series of sustainable development solutions: using environmentally friendly materials, solar power systems, reusing rainwater and treating recycled wastewater. The ratio of green land in the factory exceeds current standards, helping to improve the microclimate and ecological balance of the production area.

The factory architecture makes the most of natural light and energy, significantly reducing the need for daytime lighting. At the same time, the production line equipment system is selected based on energy-saving and high-performance criteria, ensuring product quality while minimizing operating costs and carbon emissions.

Combined with an intelligent energy management system and automatic operation monitoring, the factory will be a solid foundation for Omoda & Jaecoo to realize the goal of sustainable, environmentally friendly and globally standardized production in the automotive industry.

Keep your promise

“We believe that manufacturing in Vietnam not only helps optimize the supply chain, but also creates real value for the economy, society and consumers. Everything Omoda & Jaecoo Vietnam has ever committed to – we are doing seriously, with a clear roadmap and specific goals.” – Mr. Liu Yong Hu, General Director of Omoda & Jaecoo Vietnam shared.

From a new brand, Omoda & Jaecoo Vietnam is gradually asserting itself as one of the fastest growing and most comprehensive automobile enterprises in Vietnam – from products, services, distribution system to production and social commitment. The factory project in Hung Yen (formerly Thai Binh) is the strategic piece for this brand to go further – not only in Vietnam, but also on the global automobile industry map.

Source: https://khoahocdoisong.vn/omoda-jaecoo-tang-toc-xay-dung-nha-may-oto-tai-viet-nam-post2149060769.html

![[Photo] Ready for the 2025 Fall Fair](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/14/1760456672454_ndo_br_chi-9796-jpg.webp)

![[Photo] General Secretary To Lam chairs the meeting of the Central Steering Committee on science, technology development, innovation and digital transformation](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/10/15/1760500443782_anh-man-hinh-2025-10-15-luc-10-52-47.png)

Comment (0)