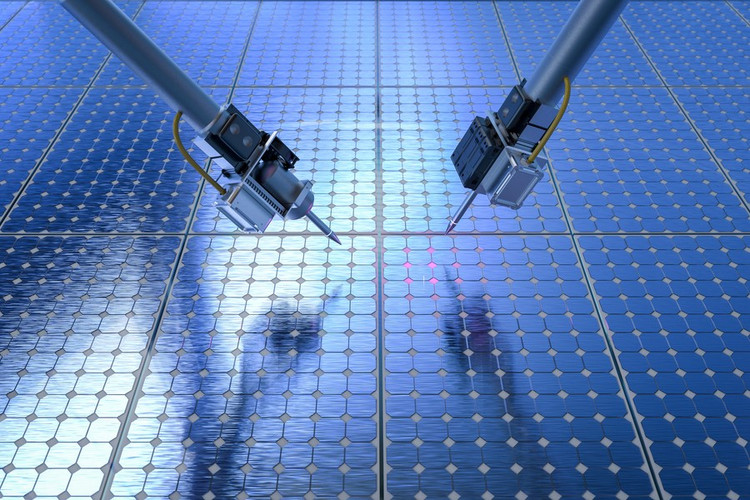

An AI-powered robotic system developed by the Massachusetts Institute of Technology (MIT) has just been announced as being able to measure material properties at an exceptional speed, about 100 times faster than human manual operations. In 24 hours of testing, the system completed more than 3,000 optical conductivity measurements – an important property in evaluating semiconductor materials, especially new ones used in solar energy technology or electronic components.

The system uses a high-precision robotic arm, integrated camera and unsupervised learning artificial intelligence model. The robot is able to recognize the surface of the material sample, divide it into potential measurement areas, and select the optimal contact point to collect the most valuable data. The movement between measurement points is also optimized by an intelligent path planning algorithm, saving time and reducing equipment wear.

With an average processing capacity of more than 125 measurements per hour, the system significantly reduces the time required for laboratory research, which is often limited by the speed and accuracy of manual operations. In the materials industry, each experimental formulation requires hundreds of measurements, and the process of selecting suitable materials can take months or even years. The introduction of robots speeds up the testing and screening cycle while significantly reducing labor costs.

One of the highlights of the robotic system is its ability to adapt to different types of material samples. Artificial intelligence not only helps the robot determine the appropriate contact position, but also automatically calibrates the measurement parameters to suit each type of material with different shapes, sizes and light reactions. The system also operates continuously without being affected by fatigue or repetitive errors – problems often encountered in manual operations.

In addition to its application in perovskite research – the material that will become the next generation of solar cells – this automated measurement technology can be widely deployed in electronic materials, sensors, displays and micro-components. With the ability to operate 24/7, these robotic systems can become part of a fully automated laboratory chain, connected to equipment for chemical preparation, material synthesis and data analysis.

Building labs that require no manual intervention is a strategic trend at many major materials research centers. Systems like MIT’s measuring robot not only increase efficiency but also ensure consistency in data quality, thereby contributing to increased confidence in modeling and predicting new materials.

As the world pushes for technological innovation in the energy, electronics and environment sectors, such automated platforms will play a vital role in shortening the time to market for high-tech products. AI robots are becoming more than just a supporting tool; they are becoming a major force in the innovation process of the 21st century.

Source: https://khoahocdoisong.vn/robot-ai-cua-mit-do-vat-lieu-moi-nhanh-gap-100-lan-con-nguoi-post1553960.html

Comment (0)