At the COP26 Conference, Vietnam was one of the countries that announced a target of net zero emissions by 2050. Compared to the 2020 Nationally Determined Contribution (NDC 2020), the updated 2022 NDC (NDC 2022) Vietnam increased its unconditional emission reduction contribution to 2030 from 9% to 15.8%; and its conditional contribution from 27% to 43.5% (compared to the BAU scenario).

| Over the past 10 years, Hai Phong Thermal Power has continuously made efforts towards green production and reducing greenhouse gas emissions. |

Along with the Law on Environmental Protection 2020, the Government has issued Decrees and decisions such as Decree No. 06/2022/ND-CP regulating the reduction of greenhouse gas emissions and ozone layer protection; Decision No. 01/2022/QD-TTg promulgating the list of fields and facilities emitting greenhouse gases that must conduct greenhouse gas inventories; Circular No. 01/2022/TT-BTNMT detailing the implementation of the Law on Environmental Protection on climate change response ...

Accordingly, along with other industrial production sectors, thermal power is one of the production sectors that must conduct inventory reports and reduce greenhouse gas emissions according to No. 01/2022/QD-TTg.

Previously, Resolution No. 24-NQ/TW of the Central Committee in 2013 on climate change response, strengthening resource management and environmental protection was the foundation of Vietnam's socio -economic development axes. In which, the most important goal is to reduce greenhouse gas (GHG) emissions and respond to climate change.

Over the past 10 years, the energy sector, especially the thermal power sector, has made an important contribution to the socio-economic development process, but it is also the sector with the highest proportion of greenhouse gas emissions. In addition, the thermal power sector is also considered to be greatly affected by the global climate change situation, such as changes in air and water temperatures will affect the power generation efficiency of thermal power plants, higher air thermal power will reduce the power generation efficiency of thermal power plants, increased water temperature can adversely affect the operation of cooling systems of thermal power plants.

Hai Phong Thermal Power Plant I and Hai Phong Thermal Power Plant II, consisting of 04 units with a total capacity of 1,200 MW, invested by Hai Phong Thermal Power Joint Stock Company (abbreviated as Hai Phong Thermal Power), are national key projects, located in Tam Hung commune, Thuy Nguyen district, Hai Phong city. With an average annual electricity output of about 7.2 billion kWh, the Plant has actively contributed to the country's industrialization and modernization as well as ensuring national energy security.

Realizing that the impacts of climate change are becoming increasingly urgent, in recent years Hai Phong Thermal Power has focused on providing solutions and plans to proactively respond to climate change, increase the rational use of raw materials and input resources, and promote environmental protection in production activities.

| Hai Phong Thermal Power Plant has covered 20% of the entire factory area with greenery. |

Mr. Duong Son Ba - General Director of Hai Phong Thermal Power Joint Stock Company said: Regarding emission management, the company chooses advanced technology to install dust filtration and flue gas desulfurization systems, ensuring emissions are discharged according to regulations. Chimney emissions are always monitored by an automatic monitoring system, continuously monitored to have timely adjustment measures when pollution parameters are at risk of exceeding the threshold.

The factory's wastewater includes industrial wastewater and domestic wastewater, which is currently collected and treated in a closed cycle. The treated water has parameters that meet the requirements of national technical regulations and is reused to operate the slag discharge system, ensuring no discharge into the environment.

For cooling water, the company has installed automatic wastewater monitoring equipment before discharging it to the receiving water source with parameters of flow, temperature, and residual chlorine in accordance with the provisions of Decree 08/2022/ND-CP. Automatic monitoring data of cooling wastewater has been transmitted directly to the Department of Natural Resources and Environment for monitoring and supervision according to regulations. Periodically every 12 months, the company conducts inspection and calibration of automatic and continuous monitoring equipment in accordance with the provisions of Circular 23/2013/TT-BKHCN dated September 26, 2013 and Circular 07/2019/TT-BKHCN dated July 26, 2019.

In addition, hazardous waste management is strictly managed and complies with the provisions of the law on hazardous waste management. Specifically, the hazardous waste of the Factory has few types but the volume is large and frequently generated due to equipment maintenance and repair. Hazardous waste such as oil-contaminated rags, oil-contaminated water, used grease are collected by the company and stored in the hazardous waste warehouse and then transferred to the treatment unit in accordance with the law.

For domestic waste management, all generated domestic solid waste is classified at the source, then collected and stored in the company's temporary domestic solid waste storage area before being transferred to a unit with the function of transporting and treating domestic solid waste in accordance with regulations.

Greening work is also given special attention by the company and is carried out periodically every year. On the occasion of Tet every year, the company organizes for employees to plant more trees in areas within the factory with the amount of planting from 200-300 trees each year to increase the green area of the factory.

"Currently, the green area of the Factory campus has reached about 12 hectares (20% of the area) and casuarina trees have been planted as dust-blocking fences in the coal port area, coal storage and slag disposal pond. The Company has proactively coordinated with experts in the field of mixed coal combustion to research and apply it to the Factory to help reduce the possibility of emissions. At the same time, every year the Company sends staff to study in advanced countries in the field of management and operation of thermal power plants to proactively approach solutions in fuel conversion towards using green fuels." - Mr. Duong Son Ba said.

In particular, to implement solutions to reduce greenhouse gas emissions according to the annual roadmap in accordance with the provisions of Decree No. 06/2022/ND-CP dated January 7, 2022 of the Government, the company has proactively implemented the project to upgrade the exhaust gas treatment system with an estimated investment capital of about VND 2,800 billion. Currently, the company is speeding up the preparation of reports, requesting approval from all levels and soon putting them into implementation.

Source

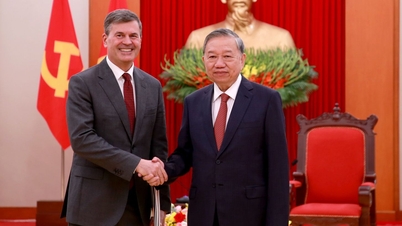

![[Photo] General Secretary To Lam receives the Director of the Academy of Public Administration and National Economy under the President of the Russian Federation](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F08%2F1765200203892_a1-bnd-0933-4198-jpg.webp&w=3840&q=75)

Comment (0)