After 4 years of research, young man Nguyen Hoang Viet and his colleagues invented an automatic rice paper coating machine system with closed technological processes, contributing to improving the quality of Dai Loc rice paper specialties and expanding the consumption market.

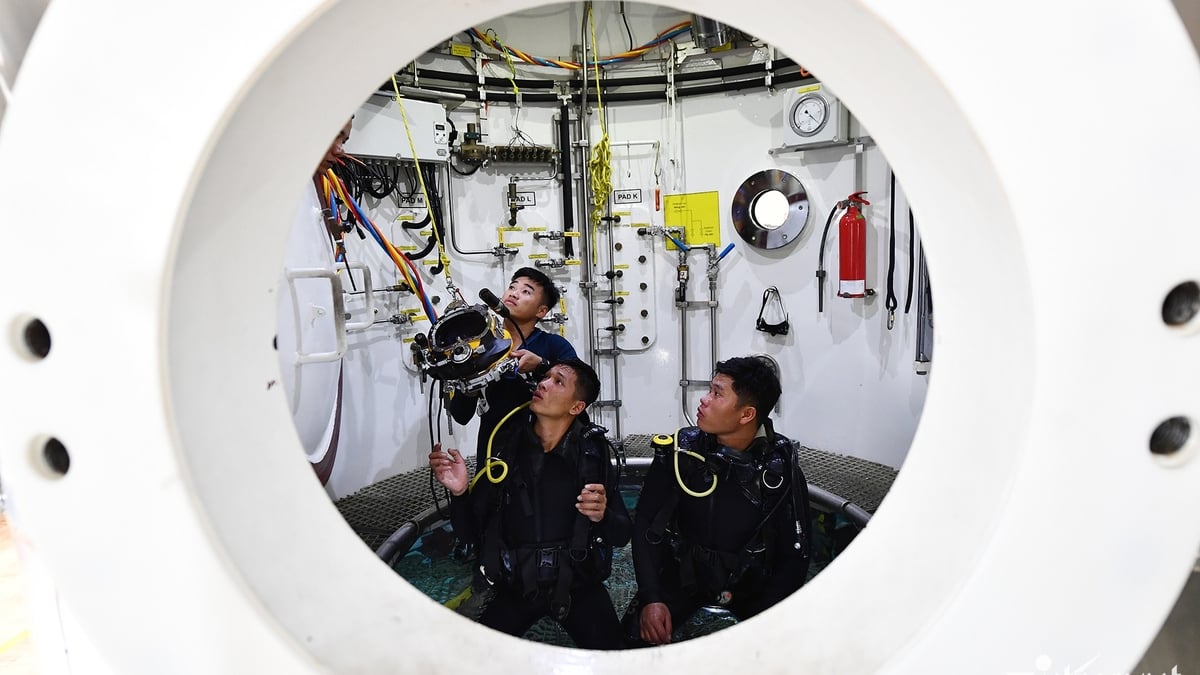

Calorifer drying technology

Mr. Nguyen Hoang Viet (born in 1989) and his friends Nguyen Thai Hieu, Mai Ba Quoc Ninh, Le Thien Tam, and Nguyen Xuan Van are all from Dai Loc district. They used to work in the mechanical field, assembling machines at cassava starch processing factories in various provinces/cities.

While working at the company, Mr. Viet and his friends nurtured the idea of researching, designing, and assembling a modern, closed production line to produce Dai Loc rice paper.

The group of young people spent time studying and researching the traditional rice paper production processes and stages and designed, constructed, and assembled a complete system with each type of machine responsible for a production stage.

In 2020 - 2021, the group built a fairly simple machine system, but when applied in practice, it did not meet the requirements. After visiting some production lines of cassava noodles and Tay Ninh rice paper, the group also quit their jobs at the company to focus more on this "brainchild".

After that, the group started trial production to complete the product. During the 2023 Lunar New Year, Mr. Viet's facility produced the first batch of rice paper with about 1 ton of rice paper, supplying a business to give Tet gifts.

“The work of perfecting the technology and improving product quality continues,” said Anh Viet. “From now until the end of 2023, we will continue to produce a number of batches and through production practices, we will continue to evaluate and improve. We want to bring consumers the highest quality and safest products.”

The automatic cake coating line consists of many main machine systems and each stage is handled by one machine. These are the rice washing machine, soaking tank, screw conveyor feeding rice to the grinder, level 1 and 2 grinders, flour tank, cake steamer (including coating machine), cake drying unit (including drying oven, calorifer) and food area (cutting, packaging, labeling...).

“The technological line allows production of up to 1.5 tons of cakes per day. Because it is a closed line, if just one stage is blocked, the whole system has to stop, so restarting it is very difficult. This forces us to perfect the technology,” Mr. Viet shared.

From the preliminary processing to milling, coating, steaming, drying, cutting, packaging, vacuuming, and bagging, all are done by machines. The rice is washed in the washing pot, pumped up to the soaking tank to let the starch expand, making the cake delicious, soft, and clear. Continuing to go through the level 1 and level 2 fine grinding system, the rice flour is sucked up and pumped up to the cake coating conveyor system.

The finished rice paper is then put through a steaming, drying, cutting, and packaging system. The advantage of Calorifer drying is that it is closed-loop drying using indirect hot air technology, helping the product to dry evenly, be delicious, flexible, clean, and free of impurities and dust. Up to now, Mr. Viet's group has invested more than 2 billion VND in research and perfecting modern production technology.

Improve the quality of traditional specialties

For a long time, rice paper production facilities in Dai Loc mainly used semi-automatic machines in the rice paper spreading and drying stages with small and medium designed capacity. Many manual production facilities take advantage of sunlight to dry rice paper.

Faced with increasingly stringent market demands, the production model with modern, clean technology, ensuring export standards and safety for consumers’ health of Mr. Viet and his colleagues is a sustainable direction. With this technology, Mr. Viet’s group is determined to improve the quality of traditional specialties of his hometown to expand the market.

The young people have also established a joint company with the trading name of BADALOC Vietnam Co., Ltd. with the goal of developing more systematic production and business. In addition to rice paper, the company also has dry noodle products.

From now until the end of the year, BADALOC Vietnam will strive to research, improve production capacity, and promote product supply to customers through promotion, marketing, and product display at fairs and exhibitions in and outside the province.

"We are trying to access support resources from the province and district to have more motivation to complete the remaining stages, bringing the product to meet provincial OCOP standards" - Mr. Viet said.

Source

![[Infographic] Traditional friendship and good cooperation between Vietnam and Egypt](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/8/4/9a2112b4046e4c128fdcb5403489866a)

Comment (0)