The faucet manufacturing industry in Vietnam is marking an important turning point with the combination of modern technology and commitment to sustainable development. Typical of which is the application of PVD (Physical Vapor Deposition) coating technology - an advanced solution that helps increase durability, anti-corrosion, and brings a shiny, sophisticated surface. Domestically produced products with international quality standards not only affirm domestic technological capacity but also meet the trend of green living and enhance modern living spaces.

Domestically produced products with international quality standards not only affirm domestic technological capacity but also meet the green living trend and enhance modern living space.

PVD (Physical Vapor Deposition) coating technology is considered a breakthrough in surface protection technology. The PVD coating process includes 3 main stages: First, the product is thoroughly cleaned to ensure there are no impurities, helping the coating adhere more firmly. Next, the metal is heated to a vapor state in a vacuum chamber, often using elements such as titanium, chromium, or zirconium. Finally, the metal particles in vapor form will adhere to the surface of the product, creating a durable and high-gloss coating.

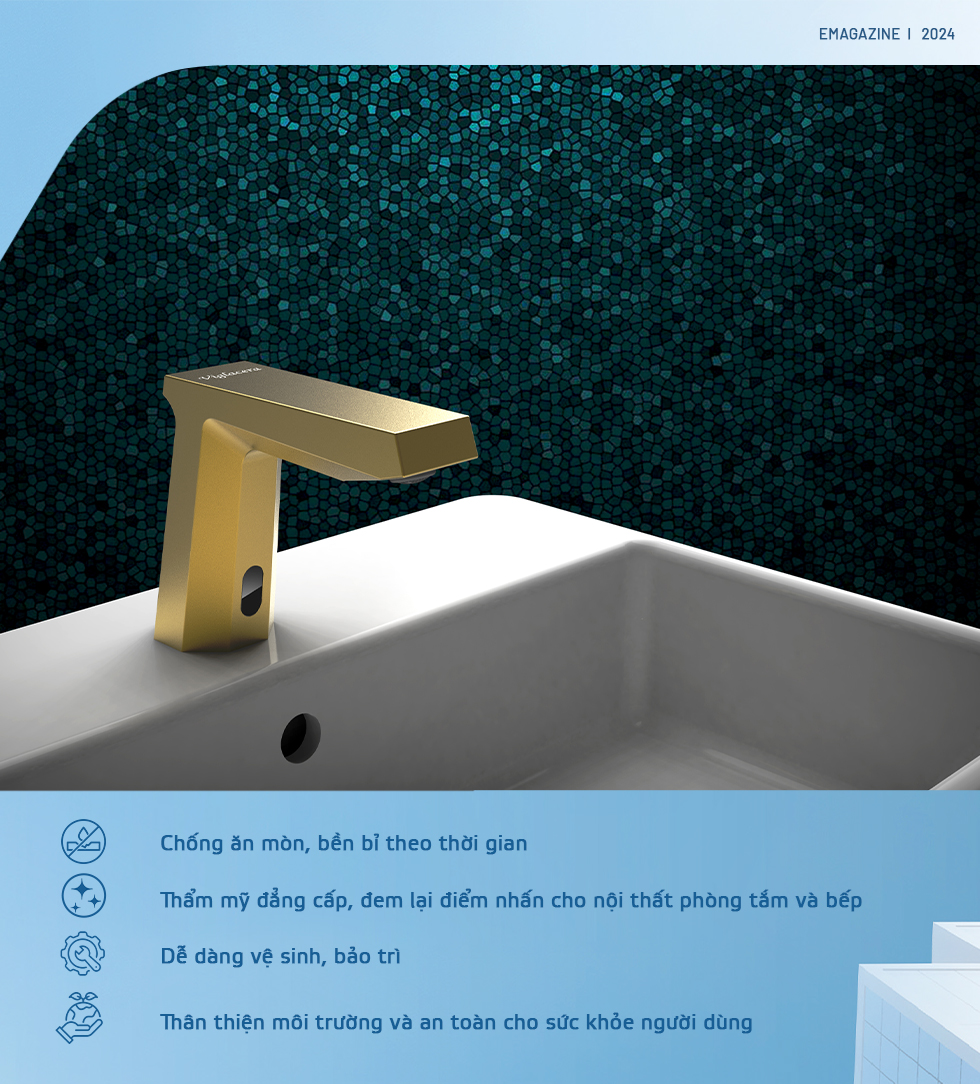

One of the biggest strengths of PVD coating technology is its ability to create a durable and aesthetically pleasing surface protection layer. PVD coatings can maintain their original beauty for a long time. PVD technology is 5-10 times more resistant to corrosion, even in environments exposed to chemicals and high salt content. This is very important for bathroom equipment, especially in resorts or homestays near the sea - places that are often in direct contact with water, moisture and salt.

With a variety of colors, this technology allows manufacturers to customize to suit many different interior styles. The surface of the PVD coating also has a natural light reflection, bringing a sophisticated and high-class feeling.

This is also considered an environmentally friendly solution. PVD coating uses vacuum technology, does not produce harmful chemicals and minimizes emissions. This process helps protect the environment and save energy, in line with the sustainable development trend of the construction industry.

In the construction industry, PVD coating is often used to coat the surfaces of tiles, glass, or decorative metal details, helping to increase the durability and aesthetics of the project.

Over the years, PVD coating technology has rapidly become a new standard in the sanitary equipment industry in many developed countries, especially in demanding markets such as Europe. Here, showerhead products using physical vapor deposition technology are highly appreciated not only for their superior quality and long-lasting durability, but also because this technology is environmentally friendly and ensures absolute safety for the health of users.

In Vietnam, the PVD coated shower faucet market is still quite new. Previously, consumers could only access PVD coated products through the channel of importing high-end furniture at high prices. This created a big barrier, preventing most consumers from having the opportunity to experience this advanced technology. Instead, popular shower faucet products in the domestic market use other color plating technologies such as electrostatic, although cheaper but have many limitations in terms of durability, scratch resistance, corrosion resistance and safety when exposed to water for a long time.

Realizing this gap, Viglacera has applied PVD coating technology on showerheads, creating a significant change for the domestic sanitary equipment industry. Not all sanitary equipment manufacturers are willing to participate in this "big game" for two reasons: The investment cost is very expensive and the high-end PVD coated showerhead market in Vietnam is still very new.

Being a pioneer in opening the market means being willing to invest time, effort and money in orienting consumer trends in choosing sanitary equipment products with high usage value.

Vietnamese people are increasingly concerned about the connection between daily-use products and personal health, family health and the living environment. Viglacera's PVD-coated showerheads completely meet these strict requirements thanks to their outstanding features of durability, aesthetics and health safety. At the same time, PVD-coating technology also contributes to environmental protection by minimizing the use of toxic chemicals in the production process.

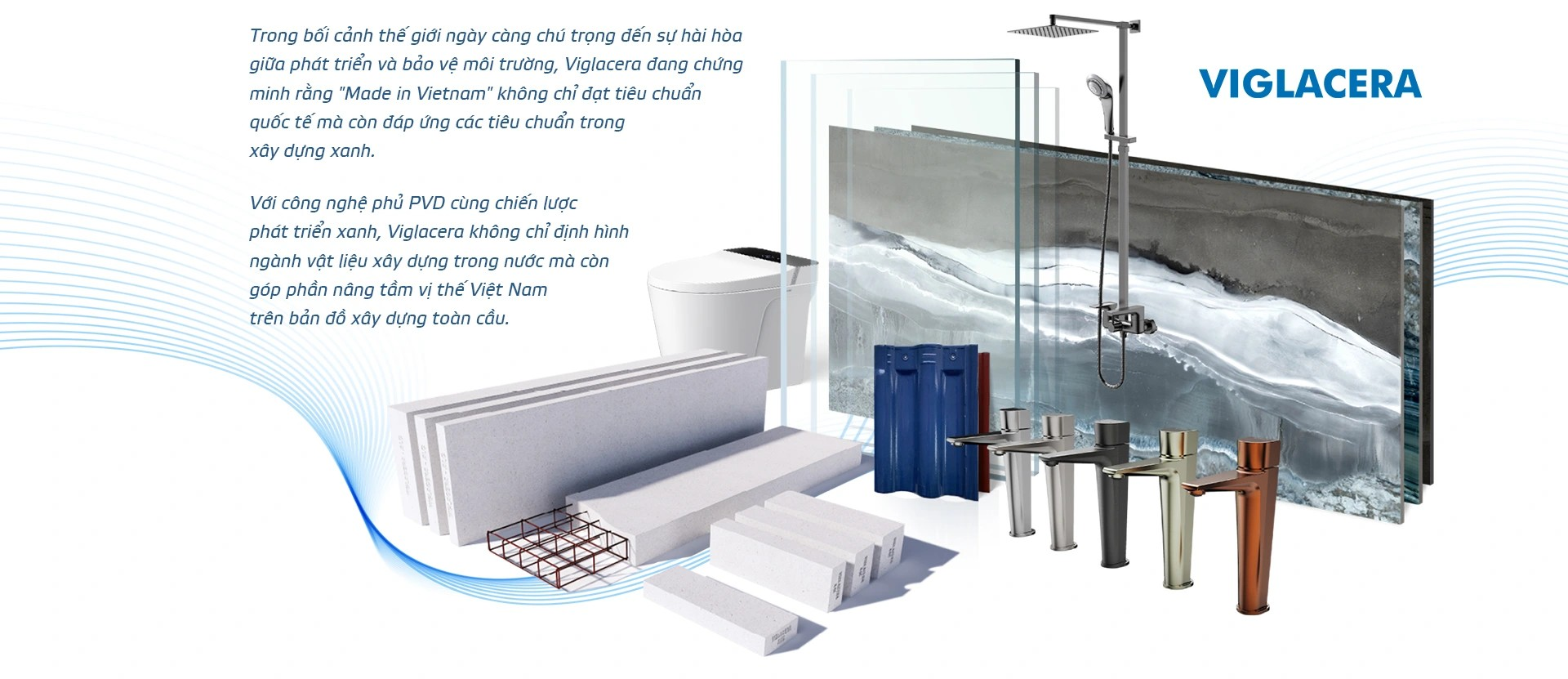

PVD coated faucets are a typical product line in Viglacera's green building materials ecosystem. All products in this ecosystem are researched and developed based on three core criteria: saving resources, reducing emissions and optimizing user experience. Not only stopping at PVD coated faucets, Viglacera also invests in researching modern technologies in the production of sintered stone, ceramic tiles, energy-saving glass and smart sanitary equipment. Each product has the mission of contributing to a sustainable, environmentally friendly construction industry and meeting the strict standards of the international market.

In the context of the world increasingly paying attention to the harmony between development and environmental protection, Viglacera is proving that "Made in Vietnam" not only meets international standards but also meets standards in green construction.

With PVD coating technology and green development strategy, Viglacera not only shapes the domestic construction materials industry but also contributes to raising Vietnam's position on the global construction map.

As a leading unit in the construction materials industry in Vietnam, Viglacera continuously invests in research and development to expand its product portfolio and improve quality. In addition, cooperation with international strategic partners, such as experts from Italy, Germany and Japan, also helps Viglacera ensure global competitiveness and bring Vietnamese consumers the most advanced products.

The commitment to sustainable development does not stop at products. Viglacera also focuses on green initiatives in the production process, such as using renewable energy, wastewater management and recycling materials. This not only helps to minimize the impact on the environment but also demonstrates the company's social responsibility in building a sustainable future for the community.

Information about PVD surface protection coating technology on faucets:

[embed]https://www.youtube.com/watch?v=ol8Fsnnd1k8[/embed]

Source: VTV

Source: https://www.viglacera.com.vn/vi/portal/news.php/tin-tuc-su-kien/hoat-dong-kinh-doanh/sen-voi-made-in-vietnam-dot-pha-cong-nghe-xanh-tu-phu-pvd-id-10781.html

![[Photo] Chairman of the Hungarian Parliament visits President Ho Chi Minh's Mausoleum](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760941009023_ndo_br_hungary-jpg.webp)

![[Photo] Solemn opening of the 10th Session, 15th National Assembly](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760937111622_ndo_br_1-202-jpg.webp)

![[Photo] The Steering Committee of the 2025 Fall Fair checks the progress of the organization](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760918203241_nam-5371-jpg.webp)

Comment (0)