The Japan Electronics and Information Technology Industries Association (JEITA) forecasts that Japan's leading chipmakers are in need of recruiting about 35,000 more employees to meet the demand for expanding and operating semiconductor factories, and the number will continue to increase for many years to come. In that context, countries such as India, Malaysia and Singapore are also accelerating human resource training to gain a position in this strategic industry. Mr. Nguyen Vinh Quang believes that this is a golden opportunity for Vietnamese youth to go out into the world , affirming Vietnamese intelligence on the global technology map.

The semiconductor industry is one of the five strategic technology pillars ofFPT Corporation: “AI-Semiconductor-Digital-Car-Technology-Digital-Green-Transformation”. In a recent conversation, Mr. Quang shared about the human resource training strategy, the aspiration to make Vietnam a bright spot in the world semiconductor industry and the role of FPT in realizing this vision.

"Every 20 years or so, Vietnam receives a big opportunity in semiconductors"

Reporter: With a background as a microchip engineer, what is your assessment of the current Vietnamese microchip industry?

Mr. Nguyen Vinh Quang: If we look back at the history of the semiconductor industry in Vietnam, we will see: Every 20 years or so, Vietnam will face a big wave with many opportunities.

The first generation of electronic microchip engineers in Vietnam were teachers and engineers born in the 70s and early 80s, who participated in the semiconductor industry through telecommunications engineering training programs at major universities. The first milestone for the Vietnamese microchip industry was the Z181 factory under the Ministry of National Defense (established in 1979).

I belong to the generation of Vietnamese microchip engineers of the “second wave” - the 2000s, when foreign corporations began to open representative offices in Vietnam, set up microchip design companies (“design houses”) and recruit Vietnamese engineers.

Typical companies in this wave include: Renesas Design Vietnam (established in 2004), Arrives Technologies Vietnam (established in 2008), Active-Semi Vietnam (started operating in Vietnam around 2004, focusing on semiconductor design). Our generation has learned, listened and been inspired by teachers, seniors and predecessors.

Look at the Vietnamese who have succeeded in this industry, such as Ms. Le Duy Loan - the first female engineer of Vietnamese origin at the American semiconductor corporation Texas Instruments, currently a Senior Fellow of TI (a title equivalent to Vice President); Ms. Nguyen Bich Yen - the world's leading expert in the field of semiconductor materials, senior researcher of the US Soitec Group; the late Professor, Dr. Dang Luong Mo - an outstanding Vietnamese scientist in the field of microchips and semiconductors; Professor, Dr. Pham Cong Kha (currently working in Japan), Professor Le Hanh Phuc (expert in the US). I have great faith that the next generation of Vietnamese microchip engineers will not only follow in their footsteps, but also create their own mark.

Now, in the 2020s, we are welcoming a new wave, when the world has major geopolitical changes, giving Vietnam the advantage to become an attractive destination in the global semiconductor supply chain.

Reporter: What is the reason for you to return and choose FPT to develop your career?

Mr. Nguyen Vinh Quang: I started working at FPT in 2014, after nearly 10 years working at an American startup. The founder of the company is Mr. Steven Huynh, a Vietnamese American who used to work at a famous chip design company in the US. When we joined the company, we were trained from the beginning and went to Shanghai, China to work together.

That day, standing in the middle of the Huangpu River, looking at the skyscrapers covered with the signs of chip design companies around the world but not seeing any Vietnamese brand, we asked ourselves: "When will the Vietnamese have a name in this industry?"

I chose to join FPT because this is a place that has enough leadership orientation and potential to make the dream of “Make in Vietnam” come true. We believe that Vietnamese people can not only do well, but can also gradually reach regional and world levels. That is the reason why FPT invests seriously and systematically in semiconductors.

Reporter: Are FPT's "Make in Vietnam" semiconductor products commercially viable, sir?

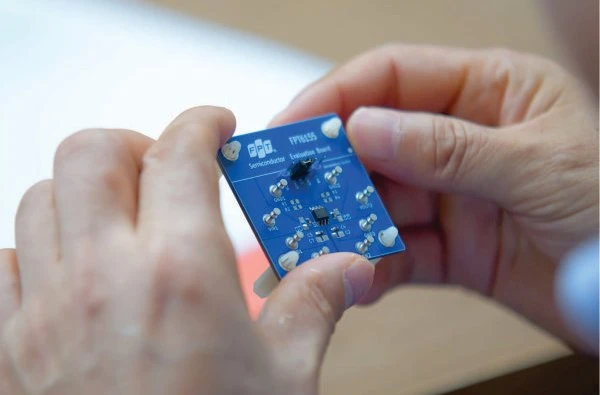

Mr. Nguyen Vinh Quang: Yes. We have successfully designed the first power chip – “Make in Vietnam” – designed in Vietnam, manufactured abroad. This is an important milestone, affirming that Vietnamese people can completely master the technology, design capacity and design process of manufacturing semiconductor products.

FPT is investing heavily in designing high-quality semiconductor products. We focus on the PMIC (Power Management IC) power chip line, an important chip in electronic devices, managing and distributing energy to electronic devices, especially in Internet of Things (IoT) applications, smart home devices and mobile devices . PMIC helps optimize the performance and energy savings of devices, ensuring stable and durable operation.

A power chip product designed by FPT semiconductor engineers. |

In the future, FPT will develop MCU and SoC chip lines, applications in IoT, automobiles, and AI, aiming to build a domestic semiconductor ecosystem. FPT expects that each engineer we are training and developing will not only be an FPT employee, but also be the one who lays the foundation for a proud “FPT Chip Inside” semiconductor ecosystem, contributing to the Vietnamese semiconductor industry.

Semiconductors – The ideal path for Vietnamese intellectual talent to reach out to the world

Reporter: In your opinion, is the semiconductor industry really attractive to young Vietnamese people? Compared to developing countries, do we have a competitive advantage?

Mr. Nguyen Vinh Quang: Semiconductors are an ideal path for young Vietnamese people to reach out to the world. Young Vietnamese engineers have many competitive advantages compared to other countries in the region.

Firstly, the young generation of Vietnam has a very good foundation in basic sciences such as Mathematics, Physics, and Chemistry. Vietnam is often in the top 5 in the world in terms of achievements in Math and Physics Olympiads. The general education program in our country has a STEM orientation, emphasizing analytical and scientific thinking, creating an ideal foundation for high-tech industries such as semiconductors.

Second, Vietnamese people are creative and enthusiastic, and have the ability to adapt quickly to new technological tools. This helps young engineers quickly access and learn how to use electronic design tools (EDA), measuring machines, and testers of foreign semiconductor companies.

Third, Vietnamese engineers are persistent and have the ability to work under high pressure. Microchip projects often last for months, even years. The Vietnamese spirit of perseverance and not giving up is an important advantage in overcoming difficult stages in product development.

Fourth, Vietnamese engineers are always eager, always dedicated, always want to develop themselves to move towards the goal of developing "Make in Vietnam" chip lines.

While developed countries like Japan and the US are lacking hundreds of thousands of semiconductor engineers, Vietnam – with its golden, dynamic population – is in an ideal position to meet this demand. This is the time for young people to turn “Vietnamese intelligence” into a global brand.

Reporter: Vietnam has set a goal of training 50,000 workers for the semiconductor industry. Is this consistent with the current market needs?

Mr. Nguyen Vinh Quang: The goal of 50,000 employees is an ambitious but modest start. Vietnam currently has about 5,000 chip design engineers, not counting packaging and testing staff (Intel alone has more than 1,000 staff specializing in packaging and testing). Vietnam has over 50 chip design companies, with demand growing at about 15%-20% per year.

Semiconductor industry is suitable for young people in Southeast Asia in general and young people in Vietnam in particular. The Asia-Pacific market is facing a shortage of up to 200,000 semiconductor engineers in the coming years. India, Malaysia and Singapore are also entering the training race.

Vietnam has the potential to exceed 50,000, becoming the region's semiconductor human resource center. Currently, our Government has recognized the importance of this field. Resolution 57 and the draft Law on Digital Technology Enterprises both have many preferential policies for the semiconductor industry: Tax exemptions, investment incentives, training support... This is the driving force for localities and businesses to join hands in developing high-quality human resources.

Mr. Nguyen Vinh Quang - General Director of FPT Semiconductor, FPT Corporation has more than 19 years of experience in the field of integrated circuit (IC) design and in the semiconductor industry. As the founder and General Director of FPT Semiconductor Joint Stock Company (FPT Semiconductor), he has led the company from a small group of semiconductor engineers to become a pioneer in the semiconductor industry in Vietnam with the vision of "Chip Make in Vietnam, Made by FPT". He expanded FPT’s semiconductor design engineering team in Japan, bringing the total number of engineers to nearly 120 in both Japan and Vietnam. Before joining FPT, Mr. Quang and the microchip design team successfully developed more than 13 PMIC (power chip) products while working at a semiconductor company based in Silicon Valley, USA. |

|---|

FPT has a roadmap to develop the "FPT Chip Inside ecosystem" for domestic application chip lines. |

The world is lacking millions of semiconductor talents: “Golden time” for Vietnamese semiconductors to affirm their name globally

Reporter: On April 28, at the Vietnam-Japan business forum chaired by Prime Minister Pham Minh Chinh and Japanese Prime Minister Ishiba Shigeru, FPT cooperated with leading corporations to provide high-quality human resource solutions in Japan and to train high-level semiconductor engineers in Vietnam, ready to participate in major projects in Japan and many other countries. NISSO leaders affirmed: it is possible to immediately employ 10,000 Vietnamese semiconductor personnel. Are we confident in the ability of Vietnamese semiconductor personnel to meet the world market, especially Japan?

Mr. Nguyen Vinh Quang: At the recent Vietnam-Japan forum, FPT signed agreements with leading Japanese corporations such as Restar Corporation - Japan's leading electronics distributor with a revenue of 350 billion yen in 2024; NISSO Corporation - a specialist in providing high-tech human resources, and MRIV - a research unit under Mitsubishi Corporation in ASEAN.

These partners not only support FPT in sending engineers to work at factories but also accompany in building 3-6 month "tailored" training programs, close to actual needs.

Providing a team of offshore engineers from Vietnam is an important part of this cooperation, showing that Vietnam is not only a destination for processing and packaging, but has entered a stage of participating in the global value chain more with intelligence.

We have every reason to be confident that: Vietnam is gradually building a force of semiconductor engineers with international competitiveness, especially in the fields of microchip design, advanced packaging and semiconductor testing - areas that are very suitable for the fabless development model and offshore services that the global market, including Japan, is in great need of.

The special thing is that we will bring advanced training programs from Japan to Vietnam, helping students access the latest technology without having to go abroad. For example, the cooperation model with NISSO and Restar allows FPT to design courses based on the specific requirements of Japanese corporations, helping students to work immediately after graduation. This is a strategic step for Vietnam to quickly fill the global semiconductor human resource gap.

FPT signed a strategic cooperation agreement with leading Japanese technology corporations at the "Vietnam-Japan Cooperation Forum on High Technology, Green Transformation and Semiconductors". |

Reporter: To achieve the goal of training 50,000 workers for the semiconductor industry, FPT University immediately opened a semiconductor training major in 2024 and has enrolled more than 1,500 students. It is known that FPT has set a goal of training 10,000 semiconductor workers by 2030. What is the difference in FPT's training program so that semiconductor engineers can work immediately after graduation, meeting the needs of the world's labor market?

Mr. Nguyen Vinh Quang: We have set a target of training 10,000 semiconductor workers by 2030 and this number can be expanded if demand continues to increase as it is now. For example, in the first year, FPT recruited about 1,000 university students to study this major. The college system currently has about 500 students.

The biggest difference in FPT's semiconductor training is the practicality and speed of updating. Unlike the traditional training model, we cooperate directly with the world's leading corporations and universities to build programs that meet market needs.

For example, the 2+2 program with Asia University (a leading semiconductor training institution in Taiwan, China) allows students to study 2 years in Vietnam and 2 years in Taiwan (China) to access advanced technology. We are also negotiating with Yongin City (South Korea) - where the Korean government has approved the planning of the largest chip center in Korea, attracting large corporations such as SK Hynix, Samsung to invest in building 6 chip factories within 25 years, with a total investment of up to 360 trillion won (about 250 billion USD).

FPT's goal is to bring the semiconductor training program to Vietnam according to the standards of leading corporations such as Samsung and SK. FPT students can participate in real projects from the second year, ensuring that they can work immediately after graduation without needing retraining. The goal is to create a team of engineers who can not only serve Vietnam but also compete in demanding markets such as Japan and the US.

Go to return – that is the spirit of the training cooperation programs that FPT builds, which means learning good things in other countries, then bringing them back to Vietnam to build the foundation for a new industry.

Vietnam has many big names in the world semiconductor industry. And young people are completely confident that they will become famous in the next era.

Mr. Nguyen Vinh Quang

Thus, by bringing semiconductor training programs from advanced countries to Vietnam, combined with training cooperation with many top training schools in the world, FPT's semiconductor training programs will be closely linked to practice to immediately provide human resources for the market after graduation.

We hope that out of the 100 people trained, many will go abroad to work, serving the global semiconductor industry. When you have achievements and a position in the industry, about 10 people will return to Vietnam to build the domestic semiconductor industry, which is a positive sign.

FPT opens the first high-tech and semiconductor R&D center at software park No. 2 in Da Nang city. |

Reporter: What message do you want to send to young Vietnamese people who are considering pursuing this career?

Mr. Nguyen Vinh Quang: I want to say that: This is a golden time for Vietnamese people to enter the big, global playground. Never before has the Vietnamese semiconductor industry received so many opportunities and support, from the country's policies and vision, the commitment to support and many incentives from the Vietnamese government, the companionship and investment commitment of many large corporations both at home and abroad, to international cooperation, especially with Japan, Korea and Taiwan (China) - countries with leading semiconductor industries.

Young people today not only have the opportunity to study but also have the opportunity to be exposed to machines and semiconductor devices, and to participate from the beginning in "Make in Vietnam" chip design projects. It is the combination of long-term vision and practical environment that will truly motivate them.

Studying semiconductors is not difficult, nor is it expensive. If you are studying related fields such as electronics or information technology, you only need 6-12 months of additional knowledge to enter the industry. Be confident, because "Vietnamese intelligence" is being awaited by the whole world. The "dream" of designing "Make in Vietnam" chips by Vietnamese engineers 40 years ago, or 20 years ago is no longer a vague image, but is being written every day by the hands and minds of Vietnamese engineers - the generation of the next 20 years and many decades later, when our country reaches out to welcome the new era.

Thank you Mr. Nguyen Vinh Quang!

Source: https://nhandan.vn/ve-tiep-giac-mo-chip-make-in-vietnam-tu-nhung-ban-thiet-ke-vi-mach-post879978.html

![[Photo] National Assembly Chairman Tran Thanh Man attends the VinFuture 2025 Award Ceremony](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764951162416_2628509768338816493-6995-jpg.webp&w=3840&q=75)

![[Photo] 60th Anniversary of the Founding of the Vietnam Association of Photographic Artists](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764935864512_a1-bnd-0841-9740-jpg.webp&w=3840&q=75)

![[Photo] National Assembly Chairman Tran Thanh Man attends the VinFuture 2025 Award Ceremony](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/05/1764951162416_2628509768338816493-6995-jpg.webp)

![[Infographic] Air pollution and recommendations from the Ministry of Health](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/05/1764950568593_screen-shot-2025-12-05-at-222015-png.webp)

Comment (0)