Digital transformation is taking place rapidly in all areas of society. According to experts, the combination of technology and production will be the decisive factor for businesses to optimize processes, reduce costs to improve competitiveness, and meet new development requirements.

The most difficult thing is to change the mindset of the leader.

Artificial Intelligence (AI) has become essential to e-commerce technology over the past decades. Its rapid development has changed the way consumers shop online. Over the past thirty years, the world economy has faced unprecedented digitalization. This process has transformed the management and operational tasks of businesses from traditional methods to technology with the aim of maintaining a competitive position in the market and securing market share.

However, according to experts, the application of digital transformation in many businesses still has many limitations. In particular, the readiness to apply 4.0 technology in production and business activities is still low, in which many businesses are facing barriers such as lack of digital skills and human resources, lack of information technology platform, lack of digital thinking or challenges of digital culture in businesses...

Furthermore, digital transformation requires businesses to invest heavily in technology infrastructure and retrain employees to be able to proficiently use new tools.

Mr. Tran Duc Tung, Deputy General Director, Hanel Manufacturing and Import-Export Joint Stock Company (Hanel PT) stated that in reality, digital transformation is not easy and the biggest difficulty for businesses is the commitment of the leadership to the strategy. If the leadership does not have a clear strategy, digital transformation will certainly be difficult to succeed.

Similarly, according to Mr. Cao Huu Hieu, General Director of Vietnam Textile and Garment Group (Vinatex), the most important thing about transformation is not whether the enterprise wants to do it or not or has the financial conditions to do it or not, but most importantly, the leader, the head of the unit must really be determined to succeed.

Vinatex representative assessed that the implementation of the digital part is very simple, but the decisive factor is the transformation. “The first thing is to change the mindset from the top leader to the leaders at all levels, they must work together for the digital transformation to be successful,” said Mr. Hieu.

Taking the example of the Fiber industry, a representative of Vinatex shared that at first, many units were not enthusiastic or interested because they found it difficult, especially since all information must be transparent, public, and have real data for management to be accurate.

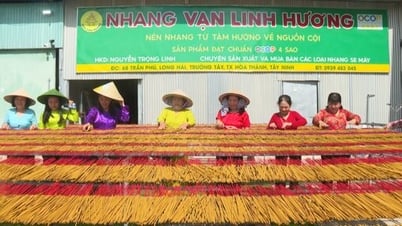

The rate of defective products of enterprises has decreased sharply thanks to the application of technology. (Photo: PV/Vietnam+)

Meanwhile, Mr. Nguyen Van, Vice Chairman of the Hanoi City Association of Supporting Industry Enterprises, said that large manufacturers have built fully automated supply chains.

Although Vietnamese enterprises cannot yet meet 100% of this requirement, it is completely possible to do so in each specific stage, in which the first requirement is technology, specifically starting with digital transformation. Digital transformation will create conditions for all enterprises to participate in the supply chain.

Seize the opportunity to succeed

It can be seen that the initial stage of transformation can be difficult, but the achievements that digital transformation brings have been proven in practice. Many businesses have significantly reduced the rate of defective products thanks to automatic quality control systems and IoT data analysis, creating a safer, more efficient and connected working environment for employees.

For example, at Vietnam Technology and Industry Group Joint Stock Company (Intech Group), with operations on a digital platform, all data is statistically collected. At the same time, having complete data helps businesses make decisions and strategies for the next stages in a scientific way.

“After the conversion, customer experience has also increased, everything is more timely. Machine warranty and maintenance are timely and strict,” said Mr. Hoang Huu Thang, General Director of Vietnam Industrial and Technical Group Joint Stock Company (Intech Group).

Currently, many "Made in VietNam" supporting industrial products have been trusted by large corporations in the world investing in Vietnam such as Samsung, LG, Apple, Honda, Toyota... and have become suppliers of a number of supporting industrial products serving the main industrial product chain.

Mr. Tran Duc Tung, Deputy General Director of Hanel Manufacturing and Import-Export Joint Stock Company (Hanel PT) said that in order to move towards smart production, businesses need to focus on standardizing operating technology (OT) and information technology (IT). In the OT part, Hanel PT has increased the automation rate to about 60% and the upcoming goal is to apply and bring automation lines to 80%..., at the same time, improve the quality of human resources through training programs to support businesses, helping the staff operate the system more effectively.

To create a stronger momentum in this field, Mr. Chu Viet Cuong, Director of the Industrial Development Support Center, Department of Industry (Ministry of Industry and Trade) said that in recent times, the Department of Industry has regularly organized activities to support businesses through the Industrial Development Support Center, such as: Supporting the application of digital transformation models and developing smart factories; the purpose is to support industrial enterprises to improve their capacity and optimize the production process, meeting the supply chain and competitive chain globally.

In addition, the Ministry of Industry and Trade has actively coordinated with multinational corporations and large FDI enterprises in Vietnam to implement many activities to improve production, enhance competitiveness and quality of human resources, digital transformation, and cooperate in developing smart factories for Vietnamese industrial enterprises.

“These support programs have been bringing positive signals to Vietnamese enterprises, creating widespread influence, helping domestic enterprises increase development opportunities and participate more deeply in the global supply chain,” said a representative of the Department of Industry./.

Source: https://www.vietnamplus.vn/chuyen-doi-so-don-bay-de-doanh-nghiep-tang-nang-suat-nang-suc-canh-tranh-post1039654.vnp

Comment (0)