Minda Vietnam Auto Parts Co., Ltd., Binh Xuyen Industrial Park (IP) operates in the field of manufacturing key assemblies and wiring assemblies for motorbikes and cars, supplying domestic and foreign motorbike and car manufacturing companies. Along with production activities to create products with outstanding features, the company always focuses on environmental protection (EP) and considers this an important criterion for sustainable development.

Minda Vietnam Auto Parts Co., Ltd., Binh Xuyen Industrial Park (IP) operates in the field of manufacturing key assemblies and wiring assemblies for motorbikes and cars, supplying domestic and foreign motorbike and car manufacturing companies. Along with production activities to create products with outstanding features, the company always focuses on environmental protection (EP) and considers this an important criterion for sustainable development.

Minda Vietnam Auto Parts Co., Ltd. is a pioneer in manufacturing smart keys for motor vehicles in the province.

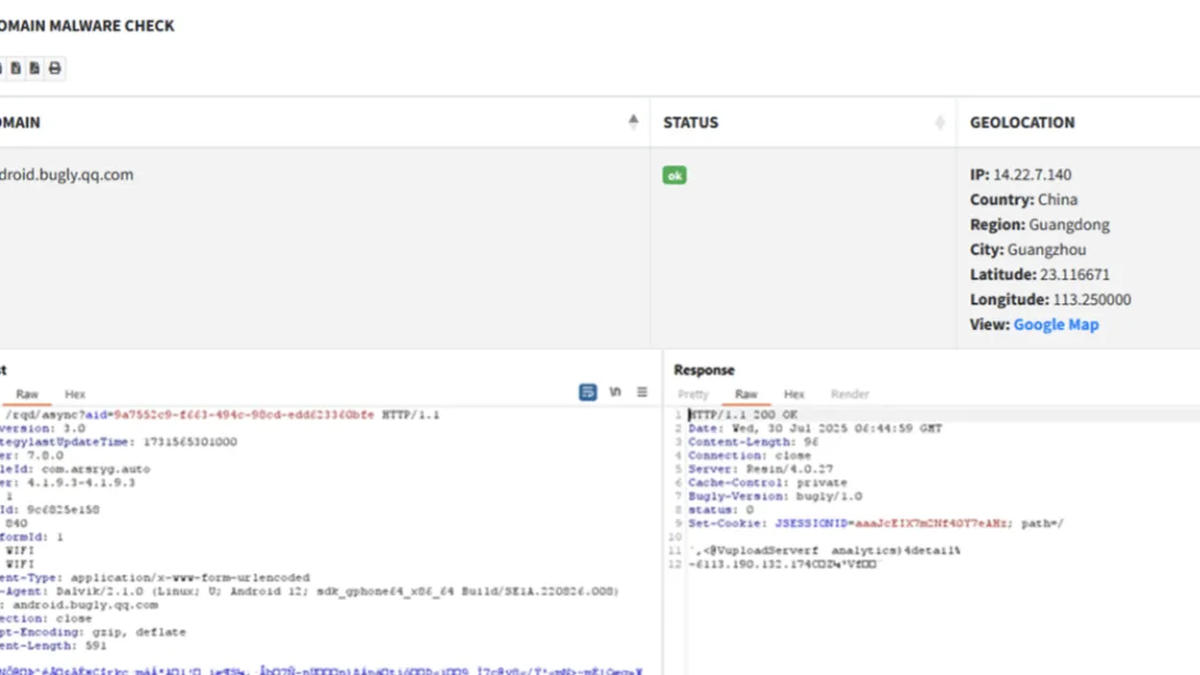

Operating since 2012, Minda Vietnam Auto Parts Co., Ltd. is one of the leading enterprises in the technology wave in the field of smart mobility in the province through investing in modern and advanced machinery systems in the process of producing smart keys (Smartkey) for 2-wheel and 4-wheel motor vehicles.

Currently, the Smartkey system has become the default equipment on cars and motorbikes being sold in the Vietnamese market. This is a product line that uses remote control technology to start and stop the engine safely, conveniently and easily.

Present in the company's clean room area, we witnessed the manufacturing process and detailed formation of this high-tech product. From the installation and running of the software programming machine containing smart coding settings for the chips to the assembly and testing of the product, all are carried out on advanced technological lines imported directly from abroad.

Mr. Vu Van Trung, technology engineer of Minda Vietnam Auto Parts Co., Ltd. said: To manufacture smart key products for motor vehicles, we go through a rigorous research and testing process.

Because the product is manufactured on a chip that applies multi-functional technology such as transmission technology, capacitive sensor, infrared sensor... combined with integrated key encryption, top anti-interference ability, low energy consumption, helping the product to create high quality and stability.

In addition, the product's shell is made of virgin plastic, contains no impurities, does not cause interference when used, helps to receive signals more easily and reduces the possibility of errors.

Currently, the company is a trusted partner of many famous automobile and motorbike manufacturers in the world such as Piaggio, Yamaha, Suzuki, Kawasaki... The company's products are guaranteed in both quality and price, not only meeting the domestic market but also exporting to many countries such as Japan, Thailand, Malaysia, Philippines... Thereby creating stable jobs for nearly 400 employees with an average income of more than 7 million VND/person/month.

Smartkey products are manufactured on modern technological lines imported directly from abroad.

Currently, the company has completed the plan to sign contracts to supply products to partners until the end of 2024 and proactively signed orders until the end of the first quarter of 2025.

Along with focusing on producing quality products, the company also pays attention to environmental protection during the production process through implementing solutions to collect and treat dust, exhaust gas, wastewater, etc.

The company installs machinery and production lines according to technical standards, regularly maintains machinery and equipment, and ensures minimal noise and vibration.

The company also equips garbage bins in the areas where they are generated, then collects and temporarily stores them in the warehouse with household waste, common industrial solid waste and contracts with functional units for transportation and treatment.

All wastewater generated at the factory is collected and treated to meet standards before being connected to the centralized wastewater treatment system of Binh Xuyen Industrial Park.

Implementing the slogan “Safety for production, production must be safe”, 100% of employees in the company are equipped with labor protection. At the same time, the company applies 5S standards to management and operation activities to increase work efficiency, increase product productivity and ensure labor safety.

Every year, the company plans and strictly implements technical management measures to prevent and respond to environmental incidents, fire and explosion incidents and risks during operations.

Director of Minda Vietnam Auto Parts Co., Ltd. Sarvesh Gupta said: Promoting existing potential, promptly seizing opportunities, creating consensus from the Board of Directors to officers, workers and employees, the company determined to continue investing in research, applying modern, environmentally friendly technologies to the production process to create high-quality products, reduce production costs, and expand the consumer market.

Along with production and business activities, the company commits to comply with Vietnamese laws on environmental protection and focuses on investing in modern waste collection and treatment equipment to protect the environment, considering this a decisive factor for sustainable development.

Article and photos: Ngoc Lan

Source

![[Photo] Nghe An: Provincial Road 543D seriously eroded due to floods](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/5/5759d3837c26428799f6d929fa274493)

![[Photo] Discover the "wonder" under the sea of Gia Lai](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/6/befd4a58bb1245419e86ebe353525f97)

Comment (0)