A small silk spinning factory in the middle of Di Linh is focusing on changing technology. With the goal of producing the best raw silk fibers and maintaining its position in the export market, Le Sau Silk Breeding Company Limited is aiming for advanced technology.

|

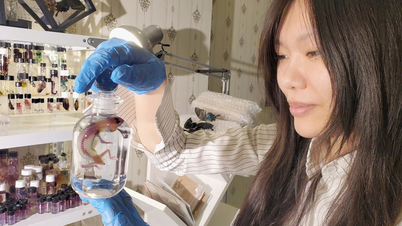

| The newly installed silk reeling machine of Le Sau Company has high capacity and saves raw materials. |

“2024 is exactly 10 years since Le Sau Company was established. From the original factory with inferior technology, we are now gradually changing, purchasing machinery, and applying technology to maintain the export market,” said Mr. Le Sau, the simple director of Le Sau Silk Incubator Company in Dinh Lac Commune, Di Linh District. Mr. Sau recalled that in the early days of establishment, with little capital, he also bought some machinery with average technology. The machinery was not modern, and after a long time of use, it became old and often damaged, with a high rate of broken silk threads, wasting raw materials. Therefore, in recent years, Le Sau has been trying to improve technology, applying production processes with the goal of making the best silk threads, Mr. Le Sau shared. He said that with the help of the Ministry of Industry and Trade, Le Sau Silk Incubator Company has applied cleaner production processes and purchased many new machinery items. At the end of 2024, the company has just assembled a new silk reeling machine, high productivity, easy to operate, saving human resources for workers and especially, limiting the situation of broken silk threads.

“Le Sau Company purchases silkworm cocoons from farmers in Di Linh as well as farmers in Lam Dong province. Our factory specializes in exporting to the Indian market. Currently, India is Lam Dong's largest raw silk market,” said Mr. Le Sau. According to him, the good news for Lam Dong's silk weaving industry is the change from root to tip. If in the past, Lam Dong silkworm cocoons were often small, weak, easily broken, and had low cocoon weight, now Lam Dong silkworm cocoons are of very high quality, with a cocoon containing 1,000 meters of silk. “The technology of growing mulberry and raising silkworms has also changed a lot, the silkworm breed is stable, and the mulberry yield is very high. Therefore, people feed and care for them properly, produce and get batches of old, heavy cocoons, which is convenient for silk weavers like us. The progress of mulberry and silkworm farmers is the first reason for the development of Lam Dong's silk industry.” Therefore, Le Sau Company always ensures a close cooperative relationship with mulberry and silkworm farmers, Mr. Le Sau assessed.

With the change in technology, purchasing and installing new machine systems, a set of incubation machines of Le Sau Company has a capacity of 4 tons of cocoons/roll. A 7-day cocoon roll produces three quintals of white, thin, tough raw silk of export quality. At the time when there are many cocoons, peak production, Le Sau Company produces 4 quintals of raw silk per day. Most of the company's silk is exported directly to India. Mr. Le Sau also commented that Indian customers, after visiting the factory as well as the Lam Dong silkworm area, were very impressed and liked it. For Le Sau Company, partners accept payment in advance and receive goods later, a method that is very beneficial for the business. Reputable customers, stable output, however, to get high-quality orders at good prices, the company must improve the quality of silk, Mr. Le Sau shared. Therefore, originating from a small local silk incubation workshop, the company actively changes technology. “Fortunately, thanks to the support from state agencies, the Department of Industry and Trade, industries and companies, we have more information as well as partially offset the costs to purchase new machinery for businesses,” Mr. Le Sau informed. In 2020, he was supported to build a cleaner production model, improve the working environment, and save input materials in production. In 2024, he received a loan of 400 million VND from the Industrial Promotion Fund, plus funding to install a modern silk reeling machine system worth nearly 2 billion VND. According to Mr. Le Sau, the capital to change machinery and technology in the silk reeling industry is very large, and it is difficult for businesses to do it themselves. With the support of the State, businesses will quickly change technology as well as purchase modern machinery and equipment.

Ms. Cao Thi Thanh - Deputy Director of Lam Dong Department of Industry and Trade said that supporting enterprises to innovate technology, reduce costs, and improve productivity and quality is always a priority of the Industry and Trade sector. In particular, raw silk is currently a very valuable export product of Lam Dong. In addition to bringing in large foreign currency, silk reeling and weaving companies have helped stabilize and increase the mulberry area, leading to the prosperity of tens of thousands of farming families. Therefore, supporting silk spinning and weaving factories is a priority of Lam Dong with the goal of sustainably developing the mulberry growing and silkworm raising profession in the highlands.

Source: http://baolamdong.vn/kinh-te/202411/doi-moi-cong-nghe-dua-to-tho-xuat-khau-7c73118/

Comment (0)