The bamboo is smoked before being whittled to create durability for the lantern product.

When we arrived, at Mr. Ha's family's house, there were many people performing different stages of lantern production. Each person had a stage, and everyone was working quickly. Some brought bamboo strips, others bought lanterns and took them away, and 7-8 workers were meticulously doing each stage to complete a complete lantern.

Mr. Le Vinh Ha said that every day, his facility exports about 700 lanterns of various types and sizes to domestic and foreign markets. Most of his family's products are sold to establishments such as restaurants, hotels, eateries, or for events taking place in the area and neighboring provinces.

Mr. Le Vinh Quoc (Ha's father) has 15 years of experience in the profession of whittling bamboo strips for lantern shops in Hoi An. He has guided his son to excel in the profession.

Sharing about the opportunity to come to this profession, Mr. Ha said that he had previously studied at a university in Ho Chi Minh City and then started his career there. He opened a large chain of coffee shops with a stable number of customers and a very good revenue. However, in the years 2019 - 2021, the Covid - 19 pandemic broke out, making business extremely difficult. Trying to survive but failing, he and his wife moved the shop to return to their hometown.

Miles are just for decoration of lanterns.

“My wife is from Ho Chi Minh City, but when I decided to return to my hometown to continue my family's lantern making business, she also supported me and returned to my hometown with me to start a business. It was not only a joy, but also a motivation to help me become more and more confident in my chosen job," Mr. Ha said with a smile.

Mr. Nguyen Tan Ngoc used to work far away, but now he has returned to study and make lanterns at Mr. Ha's family workshop (In the photo: Mr. Nguyen Tan Ngoc performs the process of creating the frame for the lantern)

With the dream of starting a business, Mr. Ha had to visit many lantern-making establishments in Hoi An to learn the experience and each step in making a complete and beautiful lantern. For him, those were precious days, he met many skilled people, and was taught the basic knowledge to complete a satisfactory product. With the profession, he returned home to start realizing his dream.

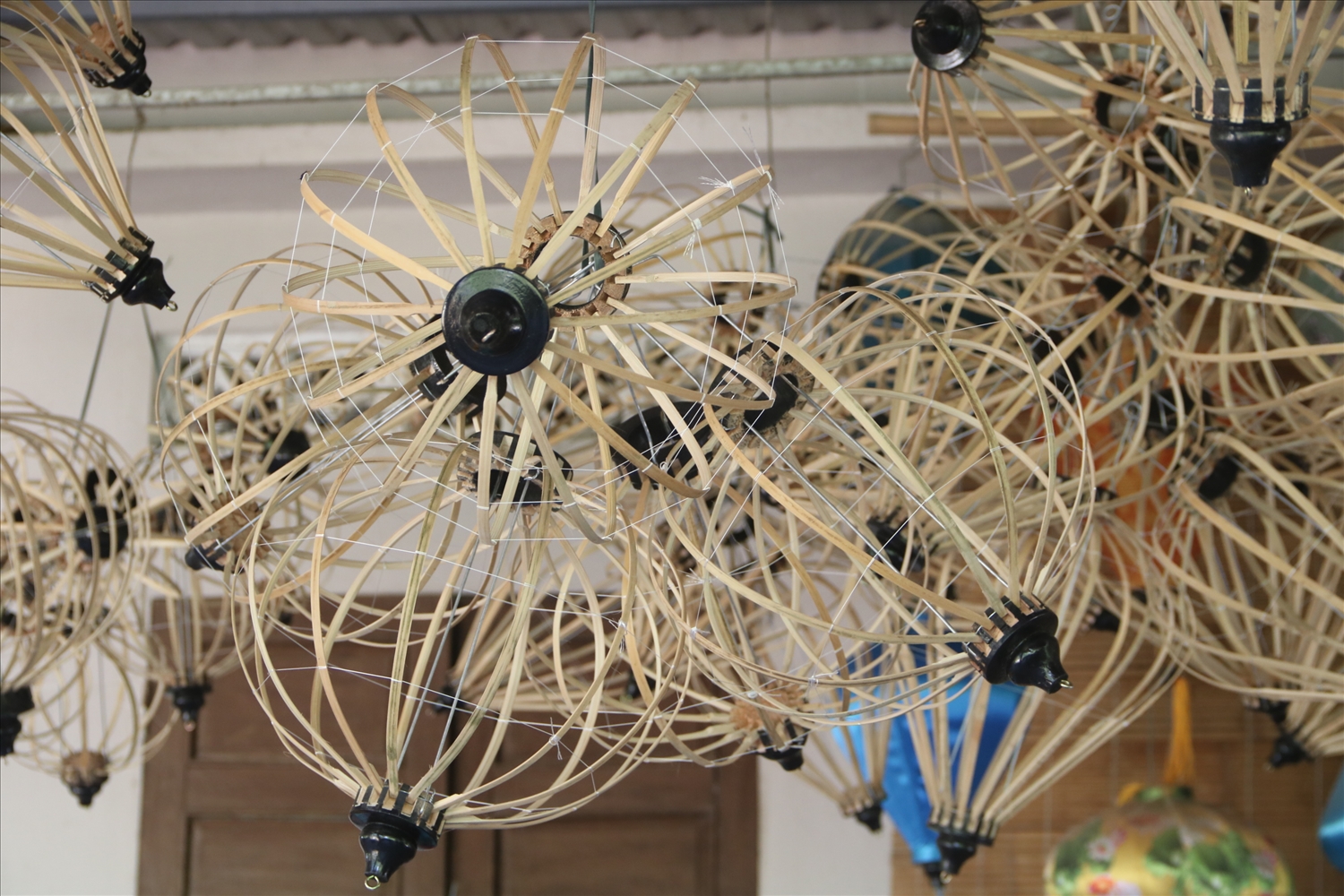

Creating the frame for the lantern is time consuming and requires meticulousness.

According to Mr. Ha, thanks to his father's connections, he and his wife have skilled workers willing to accompany them. After producing quality and unique lanterns, the output stage also makes the couple struggle.

Not giving up, he surveyed the market and sought out consumers from social media platforms. In addition, he directly introduced the product to many people at fairs and exhibitions held in Quang Nam and neighboring areas.

Lantern frames of various sizes are created by skilled craftsmen.

The year 2024 is a turning point marking the maturity and development of Thien Dang lantern manufacturing facility, when the facility's products meet 3-star OCOP standards and are favored by many customers. Not only standing firmly in the domestic market, products from Mr. Ha's facility also export lanterns to many countries, such as the United States, Chile, Colombia, Malaysia, etc.

Colorful fabric is sewn into the lantern frame according to customer requirements.

“We also promote customer retention business strategies through workshops to create souvenir products and experiences for customers. And each stage, from production to advertising, customer consulting, sales, has a specialized team to improve efficiency…”, Mr. Ha added.

The process of pressing iron into the lantern frame for strength.

According to Mr. Ha, the weather does not affect work efficiency. Even when it rains, the facility is still proactive in providing bamboo and drying kilns to make lanterns, ensuring that the product supply chain is not lost. And besides keeping customers, Mr. Ha's family also focuses on vocational training for local people to create the highest quality products.

Mr. Nguyen Tan Ngoc used to work far away, but in the past two years he has returned to study and work in the lantern making industry at Mr. Ha's family's facility with a stable income. He mainly works in the stage of creating frames for the lanterns. "Working here is quite comfortable, the treatment is good so I feel very secure. When making frames for lanterns, priority is given to strong, flexible bamboo strips so that when attached, it will create a solid, even and beautiful product," said Mr. Ngoc.

Each finished lantern costs from 80,000 to nearly 1 million VND depending on size and material.

Mr. Le Vinh Quoc (Ha's father) despite his old age still works hard to make bamboo strips for his family's lantern making business. He said that he is very happy and supports his son to start a business with the local traditional profession. With 15 years of experience in making bamboo strips for lantern warehouses in Hoi An, he has connected and guided his son and his wife to improve their skills in the profession.

Mr. Quoc said: To have good bamboo strips, you must choose bamboo with the right age, then process it through many steps such as soaking and drying it lightly before shaving the strips. "The bamboo is bought, soaked and then smoked to increase its flexibility. When shaving the strips, you must do it evenly and bend it gently to suit each type of lantern," Mr. Quoc shared.

Every year, Mr. Ha's facility has a revenue of nearly 3 billion VND.

Sharpening bamboo strips is one of the first steps in the process of creating a lantern. Once the bamboo strips are of good quality, the craftsman will thread steel wire through the bamboo strips into sets corresponding to the number of bamboo strips in a lantern. Next, the craftsman will wrap colorful fabric around the body of the lantern, and decorate the fabric with patterns.

Not only contributing to creating jobs for local people, Mr. Ha has brought Hoi An lanterns to a new level.

In addition to selling lantern products, Thien Dang also undertakes construction and decoration for resorts, hotels, restaurants, eateries, etc. for customers in need across the country. Recently, his facility has constructed and decorated lanterns for a number of hotels and eateries in Da Nang , Quang Nam, and festivals in Hoi An and Duy Xuyen areas.

Mr. Ha promotes lantern products at fairs and exhibitions...

Mr. Ha said that each lantern costs from 80,000 VND to 600,000 VND and a few are more expensive depending on the type and material. With his tireless efforts, his lantern facility now brings in nearly 3 billion VND in revenue each year, providing employment for many local people, especially during holidays and Tet.

Source: https://baodantoc.vn/9x-bo-pho-ve-que-dua-den-long-pho-hoi-ra-the-gioi-1750071430202.htm

![[Maritime News] Two Evergreen ships in a row: More than 50 containers fell into the sea](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/8/4/7c4aab5ced9d4b0e893092ffc2be8327)

Comment (0)