Construction of Deo Ca tunnel – Photo: PHO BA CUONG

That is the opinion of Associate Professor, Dr. TRAN CHUNG, Chairman of the Vietnam Association of Road Traffic Construction Investors (VARSI).

With 67 billion USD of public investment capital from the project, it will spread, thereby helping many economic sectors benefit, many manufacturing industries have the opportunity to learn, improve and develop.

* Do you agree with many opinions that when implementing investment, the high-speed railway project on the North-South axis will be a launching pad for the entire economy?

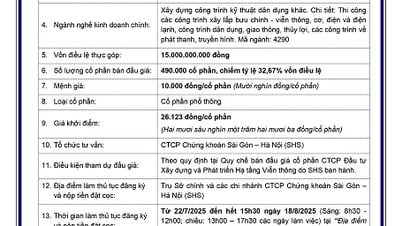

– The North-South high-speed railway project is a super-large project with historic advanced technology. Implementing this project will not only provide the country with a new type of modern transportation but also promote socio-economic development. At the same time, when implementing the project, it will create jobs for millions of workers and businesses participating in the project.

The project will be an opportunity to enhance the capacity of the entire Vietnamese economy from material production to mechanical manufacturing, infrastructure construction, electricity, digital technology , etc. All industries will be activated and developed because high-speed railway projects are not only related to the construction of bridges, roads, and tunnels, but also involve extremely important factors today such as digital technology, robots, and artificial intelligence in construction and future operations.

* We will arrange capital for the project ourselves, what advantages does this have compared to projects with foreign loans?

– Previously, when we borrowed official development assistance (ODA) to do infrastructure projects, we had to accept the conditions set by the lender regarding contractors, materials, designs, etc. On the contrary, when we have a policy of self-financing, we will have an active position in this big game.

Our ability to be self-sufficient in capital also attracts countries that are mastering high-speed rail technology, and of course we will have the opportunity to proactively choose the most advanced technology that meets our requirements.

High-speed railway is an extremely modern technology. We cannot do it ourselves, so we almost have to sign a contract with a foreign contractor to provide the technology to ensure consistency from infrastructure to equipment and control systems to ensure exploitation.

The main contract applied in this case is the EPC contract. The country that wins the bid will carry out the entire design - equipment supply - construction phase. But if we have the initiative in capital, the technology transfer conditions will be an important content to negotiate.

Nui Vung Tunnel ( Binh Thuan ) is more than 2 km long and is designed, supervised and constructed by a domestic team of consultants - Photo: TTD

* So what are the opportunities and possibilities for Vietnamese contractors to participate in the project, when we have many contractors who have built highways, bridges, and tunnels through mountains?

– Personally, I think this is an opportunity for Vietnamese people to approach and master high-speed rail technology. But to master it, we must understand it, and to understand it quickly, we must actually do it.

Regarding construction, domestic contractors have the capacity to build roads, foundations, pillars, and road tunnels, but we still lack knowledge and experience in calculating the impact of high-speed trains running on that infrastructure.

For example, we can design and construct many road tunnels, but high-speed railway tunnels are a very different design problem when the tunnel is narrower and the train speed is 350km/h (high-speed road tunnels have a maximum speed of 120km/h), causing extremely high air pressure.

We do not know the structure and solutions to reduce the pressure of high-speed railway tunnels.

Therefore, I suggest that when negotiating contracts with technology-providing countries, in addition to the technology transfer clause, there should be a clause that we accompany them from the design, production, and construction stages. I use the word "joint" because we have to do it to gain understanding, accumulate knowledge, and gain experience.

* According to you, what do Vietnamese businesses and contractors need to prepare to participate in the high-speed railway game?

– After the Politburo and the Party Central Committee approved the policy on high-speed railway on the North-South axis, I saw the excitement of many businesses. Many construction, material production, manufacturing, information technology, etc. businesses have proactively researched and learned about human resource training projects to be ready to participate.

I hope that all Vietnamese businesses will have the opportunity. But to turn the opportunity into reality, we must prepare from now, and the most important preparation is people. Experience from past work is the foundation, but we need new thinking and new knowledge.

Our construction contractors have matured greatly. Currently, highway construction sites are being replaced by machines. However, in the near future, high-speed railway projects will see the participation of robots and artificial intelligence to control quality, speed up progress, and minimize safety risks for workers.

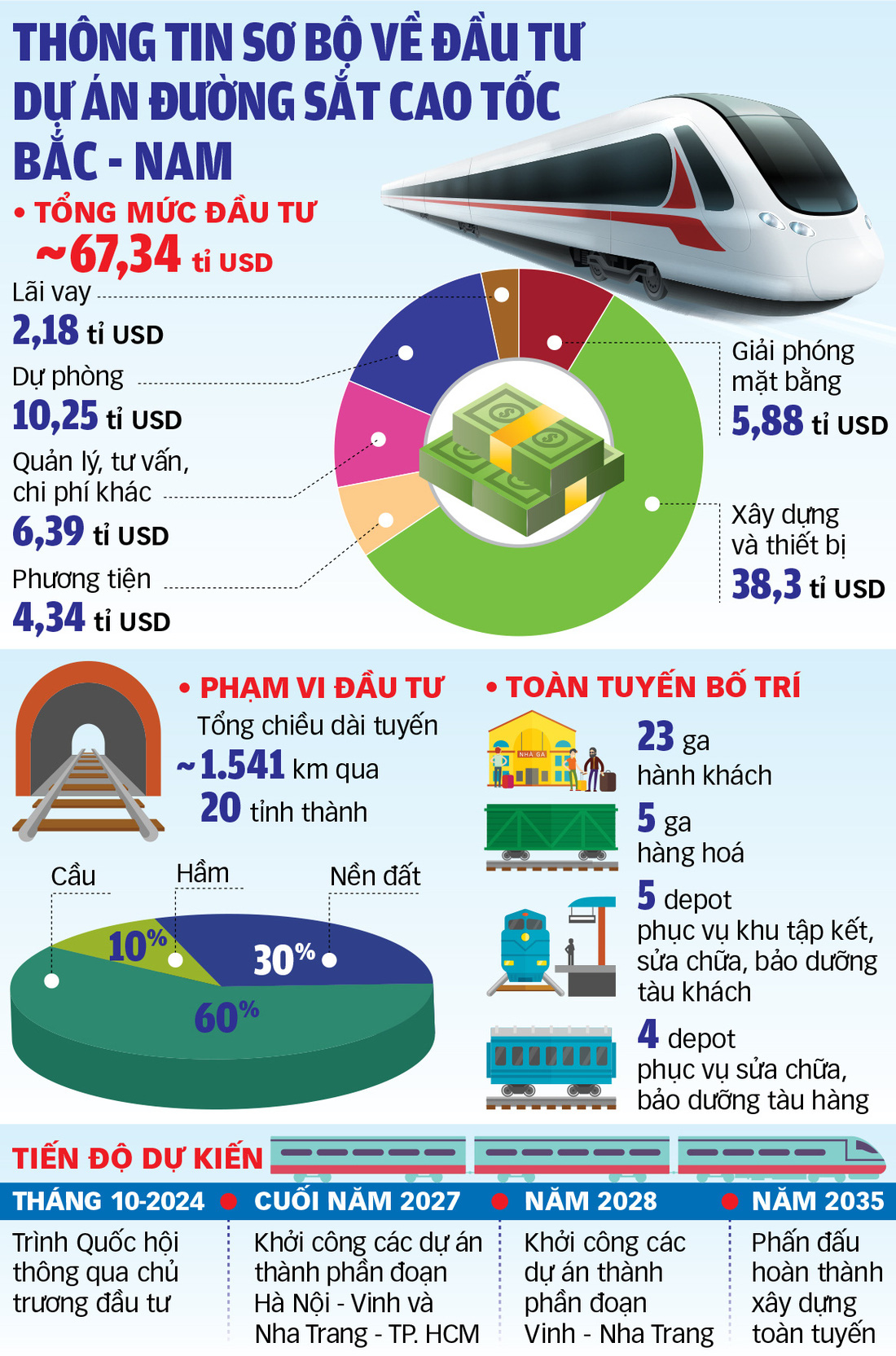

Graphics: TUAN ANH

* The opportunity for Vietnamese contractors to participate in high-speed railway projects is great but also full of challenges?

– That’s right. Currently, in many countries, robots and artificial intelligence have been involved in the construction of infrastructure projects such as bridges, tunnels, rail installation, and electrical systems. For example, in China, robots and artificial intelligence (AI) have taken on up to 40% of the workload, especially in areas with harsh climates. The involvement of modern technology not only speeds up progress but also controls quality.

The North-South high-speed railway project, with a total length of 1,541km, according to the basic design plan, has more than 900km of viaducts and 133km of tunnels. The project schedule is set at 9 years, so it is very strict. If the construction is carried out normally, without modern technology and construction equipment, it will not be able to meet the requirements.

Therefore, contractors must definitely apply new technology in design and construction to increase efficiency. Organizing scientific labor and applying advanced technology in construction are challenges that I believe Vietnamese construction enterprises will certainly overcome.

The upcoming task is new and difficult, so we must be serious and responsible to do it. We must identify this as a great opportunity to mobilize the country's resources from material production and high technology in the next 10-15 years. This is the fulcrum for Vietnamese enterprises and contractors to rise up and develop.

Need to thirst for knowledge to progress to mastery

Associate Professor Dr. Tran Chung shared that in the past, there were new technologies that we knew about but did not understand the nature of that technology so we could not master it. Many times, contractors participating in projects only knew their part of the work when assigned to do this or that but did not grasp the overall reason why they had to do it.

In fact, due to loan conditions, in the urban railway project, Vietnamese contractors participated but only in the form of assigning them to build piles and install beams without being able to access or understand more about project technology.

Therefore, we have to negotiate contract conditions so that Vietnamese enterprises can participate not only to help but also to actually do the work to understand and then master it. This is an opportunity for Vietnamese people to understand the complex issues of high-speed rail technology so that they can proactively develop their own technology in the future.

And our personnel participating in the "game" must be people who have a thirst for knowledge to explore and master.

Will ensure public debt and capital security for the project

Talking to the press about the high-speed railway project, Mr. Nguyen Duc Chi - Deputy Minister of Finance - said that this is a very large project, requiring a large amount of capital. The participation of the state budget in this project will certainly affect our public debt and public debt structure in the near future. However, the Ministry of Finance will discuss with relevant agencies and come up with different plans to ensure both goals at the same time. That is public debt safety, national financial safety and having a feasible capital plan to meet the requirements of building this project.

For more information, Mr. Le Tien Dung - Deputy Director of the Investment Department (Ministry of Finance) - said that the Ministry of Finance is actively participating with the Ministry of Transport to urgently complete the pre-feasibility study report and procedures to submit to the National Assembly in October.

To assess the impact on public debt, the ability to balance the state budget as well as allocate capital in the medium-term public investment plan from now until 2035, the leaders of the Ministry of Finance organized a number of meetings between units in the ministry.

Because in addition to the North-South high-speed railway project, there are many urban railway projects being implemented in Hanoi and Ho Chi Minh City, which are also important national projects and require a lot of capital.

Vietnamese businesses have prepared

Speaking with Tuoi Tre , representatives of infrastructure construction enterprises and material production enterprises said they were prepared to participate in the project.

From there, businesses also quickly realize the problems that need to be changed soon.

Determined to get in the game

According to Mr. Nguyen Quang Vinh - General Director of Deo Ca Group - in addition to expressway projects, investment in railway infrastructure is identified as a new direction of Deo Ca Group in the next 5-10 years.

To anticipate high-speed railway and urban railway projects, Deo Ca has cooperated with universities to recruit and train high-quality human resources in the railway industry, with a cooperation model including ordering at the source and on-site training.

Deo Ca also organizes practical research on the railway and metro training process of advanced countries such as Singapore, China, Japan, etc. through schools such as Singapore Institute of Technology (IT), Hiroshima School of Business Administration (Japan) to select and "import" training programs and experts.

Most recently, in January 2024, Deo Ca Research and Training Institute opened a specialized training program in railway and metro construction, opening a series of activities of Deo Ca Group to participate in human resource development for the transport industry, "anticipating" and meeting the urgent need for human resources, especially in the railway and metro sector.

“With this preparation, we will be determined and ready to join, not only to participate but also to try to make a specific mark in the development of the country's railway infrastructure,” said Mr. Nguyen Quang Vinh.

It is known that in addition to roads, Deo Ca Group is currently in a joint venture with IL Sung Construction Company Limited to construct package XL01 to build two railway tunnels of the Khe Net Pass railway renovation project (Quang Binh) on the Hanoi - Ho Chi Minh City railway line with a winning bid price of over 554 billion VND.

Of which, tunnel 1 is 620m long and is expected to be built in 23 months, tunnel 2 is 393m long and is expected to be built in 13.5 months; tunnel gauge is 10m, designed according to grade I railway tunnel standards.

Anticipate difficulties

Mr. Tran Dinh Long, Chairman of Hoa Phat Group, said that the group has been researching rail steel for 2-3 years. Accordingly, the production of rail steel is completely within Hoa Phat's capabilities.

This base comes from the Hoa Phat – Dung Quat production line, which is in the top technical level of the European G7 – the most modern line. This line is even more modern than many Chinese steel factories.

However, Mr. Long also said that the production of high-speed rail steel has its own characteristics with many difficulties. For example, in the past, with the North-South railway line, the rail gauge was 20-25m long. Now, to produce rail steel for a speed of 250km/h, it is necessary to produce rail steel with a gauge of over 40m, and with a speed of 350km/h, the rail gauge must be up to 100m long.

This is a problem when transportation will be very difficult, like transporting wind power poles in the terrain conditions in Vietnam.

Mr. Long added that in some countries like Japan, the steel rail factory is located right on the railway and when produced, it meets the transportation needs. But that is just an example of the difficulties in producing steel rail. Technically, producing steel rail is not difficult, but some conditions are relatively difficult.

What is the process of "upgrading" high-speed railways in other countries?

Passengers take the shinkansen train at Tokyo station, Tokyo, Japan – Photo: QUANG DINH

According to the pre-feasibility study report of the North-South high-speed railway project, there are many things to learn from other countries regarding technology transfer, industrial development and human resource training for high-speed railways.

Specifically, countries have national development programs for human resources and railway industry to prepare for investment and development; in which, the important basis for choosing the level of railway industry development is the market size and the level of industrial development.

Experience in developing the railway industry in the world shows that to develop the railway industry to fully master the technology requires a long time, through many stages and a system of developing supporting industries (metallurgy, mechanical engineering, automation, etc.), but most importantly, it needs to have a pillar in terms of market scale.

In terms of technology, only 4 countries have developed and completely mastered it: Japan, France, Germany, Italy; 3 countries have received technology transfer and are moving towards mastery: China, South Korea, Spain. Specifically:

-Korea received technology from France. After that, the Korean government established a research agency including universities and private companies to research and develop high-speed trains.

-Spain uses foreign technology (French for the vehicle part, German for the signal information part according to the European technical standards framework). After 10 years, Spain has mastered high-speed railway technology and has now exported and transferred it to many countries.

-China buys all the high-speed rail technology in the world to apply and develop its own technology. To receive, master and develop technology, China has mobilized a huge human resource of up to 25 universities, 11 research institutes and 51 technical research centers (about 68 academicians, 500 professors and more than 10,000 engineers).

Experience in China shows that with a very large railway market (about 165,000km), China has the conditions to invest, apply, test, develop and completely master the technology by spending 2.2 billion USD/year on railway research.

Zhongsha Group (China) produces high-speed trains that require 6,900 enterprises in the ecosystem, including some of the world's top enterprises.

The development of China's railway industry has gone through 5 stages (since before 1949) to achieve complete technological autonomy from 2022 to present.

* The remaining countries only receive transfers to master maintenance and operation technology, produce some materials and spare parts, aim to increase the localization rate and gradually master conventional railway technology.

The decisive moment to invest

According to the pre-feasibility report, Indonesia decided to build a high-speed railway in 2015 when the per capita income was 3,370 USD; Japan decided to build the first line (Tokyo – Osaka) in 1950 when the per capita income was 250 USD.

China decided to build the first line (Beijing - Tianjin) in 2005 when the average income per capita was 1,753 USD; Uzbekistan operated high-speed railway in 2011 when GDP per capita reached 1,926 USD; France, Germany, and South Korea invested in high-speed railway when GDP per capita was 11,106 USD (in 1981), 23,435 USD (in 1991), 16,493 USD (in 2004), respectively.

Thus, the timing of deciding to invest in high-speed railways among countries is not similar in terms of economic size and per capita income.

According to World Bank research, this is the right time for Vietnam to invest in high-speed railways when per capita income in 2023 will reach 4,284 USD (higher than many countries when deciding to invest in high-speed railways) and is expected to reach 7,500 USD by 2030.

TUAN PHUNG – L.THANH – N.AN – TP – Tuoitre.vn

Source: https://tuoitre.vn/du-an-duong-sat-toc-do-cao-bac-nam-be-phong-moi-cho-nen-kinh-te-20241003085359277.htm

![[Photo] National Assembly Chairman Tran Thanh Man visits Vietnamese Heroic Mother Ta Thi Tran](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/7/20/765c0bd057dd44ad83ab89fe0255b783)

Comment (0)