These solutions not only help save costs and increase productivity, but also pave the way for local agriculture to move towards international standard management.

Currently, modern equipment and technology are applied to production and management processes mainly such as: Drones (unmanned aerial vehicles) to spray pesticides, fertilize, detect pests; IoT (Internet of Things) connects physical devices such as machines, sensors, vehicles... with the internet to collect data, exchange information and control remotely; AI (artificial intelligence) centralized management through digital maps and satellite data; smart irrigation...

Digitalization and automation of production processes

Mr. Le Hoang Linh - Director of the Raw Material Area Project (Ia Bang Commune) of Hung Son High-Tech Agriculture Joint Stock Company - said: The Company currently has 550 hectares of South American dwarf bananas meeting GlobalGAP standards, spread across Ia Bang, Kon Gang and Bau Can communes. To develop a large raw material area, the Company has invested heavily in high-tech agricultural solutions.

The Israeli drip irrigation system helps to save maximum water usage; 3 high-capacity drones are deployed to spray pesticides, fertilize and monitor pests. One drone can manage 50 - 70 hectares/day, replacing 50 - 70 workers. In addition, the Company also uses a pulley system to transport bananas from the farm to the processing factory, along with a modern cold storage to maintain product quality...

“Thanks to the application of technology, Hung Son controls the entire production process from the banana blossom stage to harvest, ensuring the quality of the fruit in both appearance and flavor. Managing raw material areas with digital data not only helps save labor costs but also meets the strict standards of the Japanese and Korean export markets. With the production process applying technology, automating all stages has helped the enterprise achieve a production capacity of about 25,000 tons of bananas/year,” Mr. Linh shared.

Realizing the great potential of key crops, Vinanutrifood Binh Dinh Joint Stock Company invested in building a concentrated agricultural and forestry processing factory in Tay Son commune, with a large scale including production lines of 10,000 tons of animal feed, 21,000 tons of canned and instant fruits, 2,000 tons of functional foods and 5,000 m3 of cosmetics per year.

General Director Nguyen Thi Diem Hang informed that this is a strategic project to receive raw materials from growing areas in the province and neighboring provinces, and deeply process products for export. To do that, developing stable and sustainable raw material areas is the key factor.

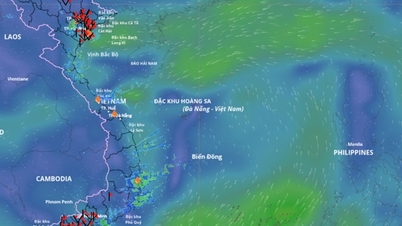

“We apply an AI-based growing area management system combined with Big Data. Thanks to that, thousands of hectares of raw materials are centrally managed through digital maps and satellite data. IoT sensors at cultivation sites collect information on humidity, pests, and weather; AI analyzes to forecast productivity, determine optimal harvest times, help reduce risks, and increase production efficiency.

At the same time, the technology also ensures transparent traceability from seeds to finished products, meeting quarantine, customs and standards requirements of major export markets, Ms. Hang said.

Transparency to enhance competitiveness

Along with the modernization of production, digitalization of product traceability is becoming an inevitable trend. This system helps consumers easily check information about the place of production, farming and processing processes; at the same time, helps businesses and management agencies effectively monitor the supply chain.

Transparency not only strengthens market confidence but also opens the door for Vietnamese agricultural products to access demanding markets such as Japan, Korea, China or the European Union (EU)... which set high standards for safety and traceability.

Digital data also supports businesses in analyzing trends, forecasting market demand, optimizing production and minimizing costs. Furthermore, transparency in product origin is a commitment to responsibility to the community and the environment, contributing to promoting the trend of safe, organic production, in line with green consumption trends and sustainable development.

Ms. Do Thi My Thom - Director of Hung Thom Agricultural and Service Cooperative (Hra commune) said: The unit is cooperating with farmers to grow more than 300 hectares of passion fruit, of which about 80 hectares meet GlobalGAP standards.

“Every year, the cooperative organizes technical training, instructs members to master the cultivation process, identify pests and diseases, and implement digital traceability, building a continuous data ecosystem. When applying digital technology , information about growing areas, production processes, technical standards, and the stages of preliminary processing, processing, and preservation are all recorded and updated on the system very transparently,” said Ms. Thom.

According to Mr. Doan Ngoc Co - Deputy Director of the Department of Agriculture and Environment: Currently, each country has its own system of standards for imported agricultural products. In addition to requirements on food safety and pesticide residues, major markets such as the EU, the US, China, and Japan also set strict regulations on growing area codes, packaging facility codes, and transparent traceability systems.

“This forces the province to re-plan the raw material areas in the direction of specialized, concentrated, and uniform quality. Along with that, the application of science and technology such as IoT sensors to monitor soil moisture and nutrition, drones to spray pesticides and observe pests on crops, and AI to support disease forecasting will become key solutions. This is not only a way to improve the competitiveness of enterprises but also an inevitable step for local agricultural products to integrate into the global value chain, towards a modern, transparent and sustainable agriculture,” said Mr. Co.

Source: https://baogialai.com.vn/gia-lai-doanh-nghiep-hop-tac-xa-quan-tri-vung-nguyen-lieu-bang-cong-nghe-post569002.html

![[Photo] Discover unique experiences at the first World Cultural Festival](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/11/1760198064937_le-hoi-van-hoa-4199-3623-jpg.webp)

![[Photo] Opening of the World Cultural Festival in Hanoi](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/10/1760113426728_ndo_br_lehoi-khaimac-jpg.webp)

![[Photo] General Secretary attends the parade to celebrate the 80th anniversary of the founding of the Korean Workers' Party](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/11/1760150039564_vna-potal-tong-bi-thu-du-le-duyet-binh-ky-niem-80-nam-thanh-lap-dang-lao-dong-trieu-tien-8331994-jpg.webp)

![[Photo] Ho Chi Minh City is brilliant with flags and flowers on the eve of the 1st Party Congress, term 2025-2030](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/10/1760102923219_ndo_br_thiet-ke-chua-co-ten-43-png.webp)

Comment (0)