A Vietnamese person will need at least 20 chips for phones, televisions, refrigerators, etc. With a population of 100 million and a young population structure, Vietnam has become an attractive market for both domestic and foreign chip suppliers.

On September 28, 2022, FPT Semiconductor - a company that designs and manufactures microchips (under FPT Software) officially announced the first microchip line applied in Internet of Things (IoT) products for the medical field, becoming the first company in Vietnam to provide commercial chips.

On October 28, 2023, the Military Industry - Telecommunications Group ( Viettel ) announced the successful research of 5G chip - one of the most complex technologies in the field of chip making.

Geopolitical changes in 2023, the central location of Southeast Asia and the tendency for scientific research and development have helped the Vietnamese chip industry enter a position of "heavenly time - favorable location - harmony of people".

Although Vietnamese chips have many outstanding advantages, up to now, 100% of electronic devices in Vietnam are using foreign chips. This shows that the road ahead for the Vietnamese chip industry still has a lot of room for development.

However, to take advantage of that potential and realize the dream of “Make in Vietnam” semiconductor chips requires appropriate directions. In the immediate future, it is necessary to promote the training of high-quality human resources, develop a startup ecosystem in the field of semiconductor chips, and issue preferential policies for semiconductor chip activities.

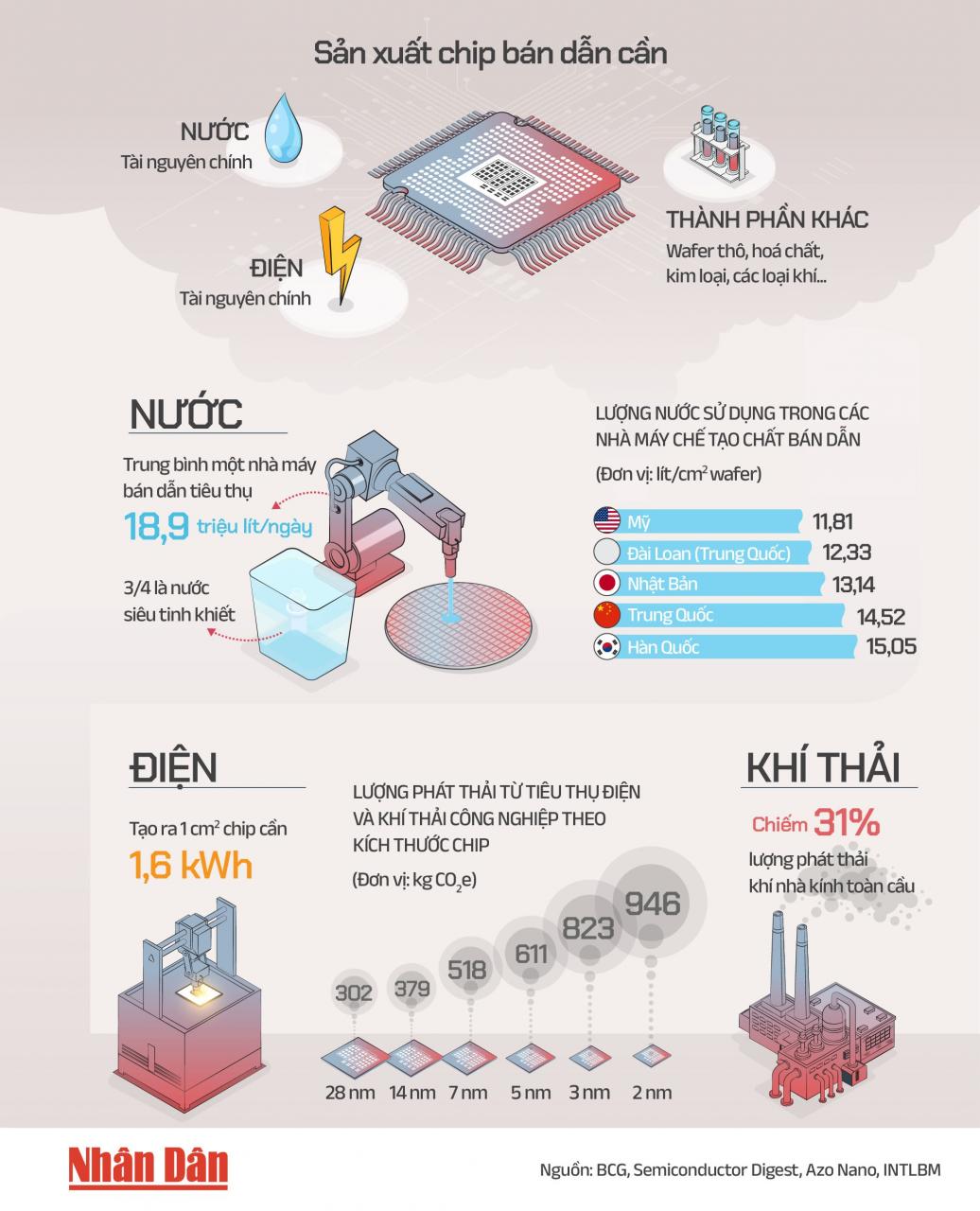

(Graphics: NDO)

Associate Professor, Dr. Nguyen Duc Minh, Head of the Electronics Department in charge of the Microcircuit Design Laboratory of Hanoi University of Science and Technology, said that, in fact, Vietnam's semiconductor industry began to emerge in 1979 when the Z181 factory (Sao Mai Electronics One Member Co., Ltd.) was established. However, when the country fell into the spiral of war and embargo, the semiconductor industry could not develop. Meanwhile, with the assistance of capital and technology from the United States, the semiconductor industry in Korea and Taiwan (China) began to develop rapidly.

“We missed a golden time when the US needed to optimize production costs and develop strategic economic and technological partnerships in the period 1960-2000,” Associate Professor, Dr. Nguyen Duc Minh commented.

On January 16, 2008, Vietnam announced its first “made in” chip. This was the product of a group of lecturers and young engineers at the Integrated Circuit Design Research and Training Center (ICDREC) of Ho Chi Minh City National University. Despite high expectations, this mark was not a commercial success.

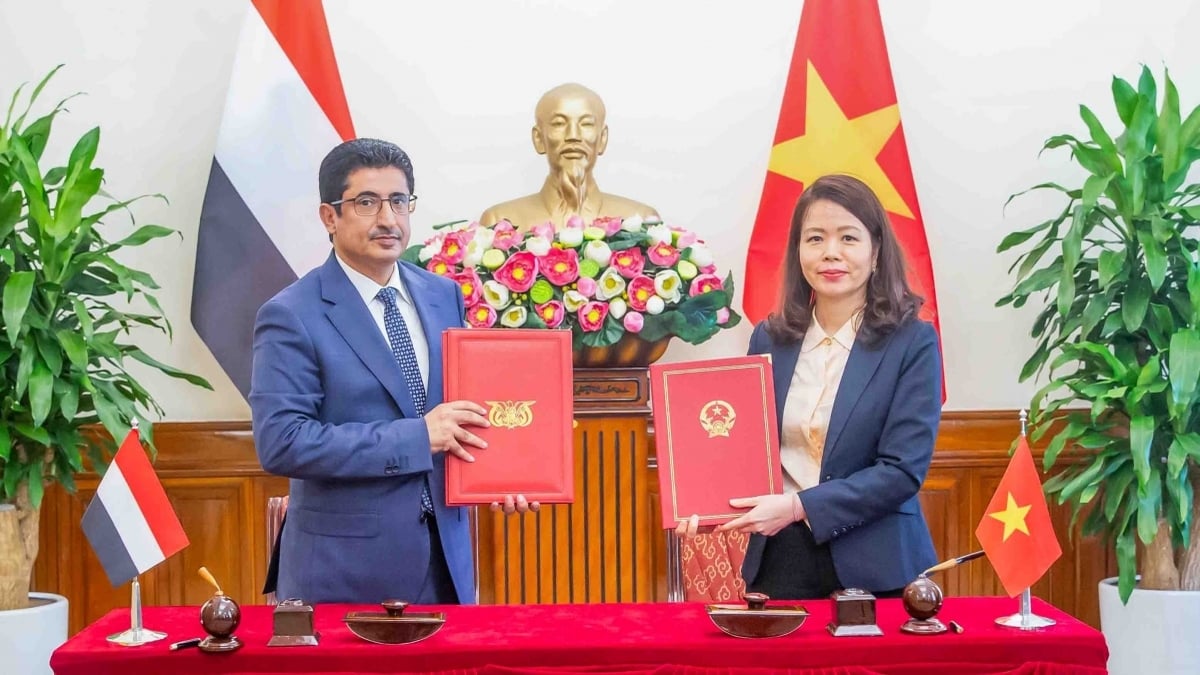

In 2023, the US and Vietnam upgraded their bilateral relationship to a Comprehensive Strategic Partnership. In a joint statement, the two countries recognized Vietnam’s potential to become a key player in the semiconductor industry. With the pandemic and geopolitical upheavals, Vietnam’s semiconductor industry has the opportunity to transform after 45 years of waiting.

According to Associate Professor, Dr. Nguyen Duc Minh, the semiconductor industry chain is highly globalized with research and development centers, microchip design centers and packaging factories spread all over the world, led by the US, Taiwan (China), Japan, Korea and Europe.

Associate Professor, Dr. Nguyen Duc Minh, Head of the Department of Electronics, in charge of the Microcircuit Design Laboratory of Hanoi University of Science and Technology.

In particular, the design stages are concentrated in the US, production is in Taiwan (China), South Korea while Japan and Europe provide important tools, machinery, and raw materials. However, after the tensions in the semiconductor supply chain related to natural disasters, epidemics, and recent geopolitical conflicts, leading countries and companies are looking to diversify their supply sources by investing in building new production and design facilities in their home countries or countries other than Taiwan (China).

“This wave of shifting supply chains in the semiconductor industry will be an opportunity for Vietnam to gradually participate in the semiconductor industry chain. From there, it will create a premise to increase productivity, quality, intellectual content and added value in products as well as in income,” Associate Professor, Dr. Nguyen Duc Minh assessed.

(Graphics: NDO)

FPT is the first company in Vietnam to produce chips for commercial purposes. In 10 years of research, FPT Corporation has developed about 25 types of chips. Most of these chip lines are mid-range technology with sizes ranging from 28nm-130nm. "We choose mid-range technology because of low investment costs, low production costs, and low selling prices," Mr. Tran Dang Hoa, Chairman of FPT Information System Company, briefly explained.

He also said that FPT's special competitive advantage over chips in the same segment from other countries lies in its exclusive chip "tailoring" technology.

Specifically, if Taiwan (China) only has one chip model to sell to all customers and all devices, FPT has the ability to personalize the chip design according to the customer's intended use, such as a separate power chip for cameras, a separate power chip for phones, a separate power chip for printers, etc.

FPT has the ability to personalize chip design according to customer's intended use.

However, this is not a very large market but requires a lot of effort. Therefore, countries with developed chip industries often only focus on high-tech chips, with little priority given to the "tailor-made" sector. These conditions have created a niche market for Vietnam, especially when the country has a great advantage in human resources.Going against the trend of starting with chip testing and packaging like many countries in the region, FPT chose chip design as the first step. Specifically, of the 25 types of chips developed, engineers in Vietnam are only responsible for the design stage. The entire production, packaging, and testing stages are all carried out abroad.

“Chip manufacturing is a large-scale problem, with investment amounts reaching billions of dollars. This is a race that consumes a lot of resources that we can hardly afford to invest in,” Mr. Tran Dang Hoa analyzed.

Mr. Tran Dang Hoa, Chairman of FPT Information System Company.

On the contrary, chip design depends mainly on people. Vietnam has a population of 100 million with many people good at math and programming, which is an important condition to establish a chip design team.

Sharing the same view, Associate Professor, Dr. Nguyen Duc Minh (Hanoi University of Science and Technology) also said that in the basic steps of the semiconductor chip manufacturing process, which are design, manufacturing, testing and packaging, Vietnam should temporarily skip the semiconductor wafer manufacturing stage in the next 10 years and focus on the design stage, forming research and development centers, and designing microchips with domestic and foreign investment capital.

“The design stage creates 50% of added value, manufacturing including wafer manufacturing creates 24% of added value, and packaging and testing create 6% of added value. In particular, wafer manufacturing requires huge investment capital, high level of science, technology and management development. The design stage requires great innovation ability to create great added value because owning the final products generates revenue” - Associate Professor, Dr. Nguyen Duc Minh explained.

In addition, according to experts from the University of Technology, anticipating the trend of shifting supply chains and establishing packaging and testing factories with foreign direct investment is also a suitable step for Vietnam.

Currently, the biggest market drivers for the semiconductor industry are artificial intelligence applications (AI chips for servers and AI chips for Internet of Things devices), and vehicle applications. These are research and development directions that Vietnam can focus on investing in development.

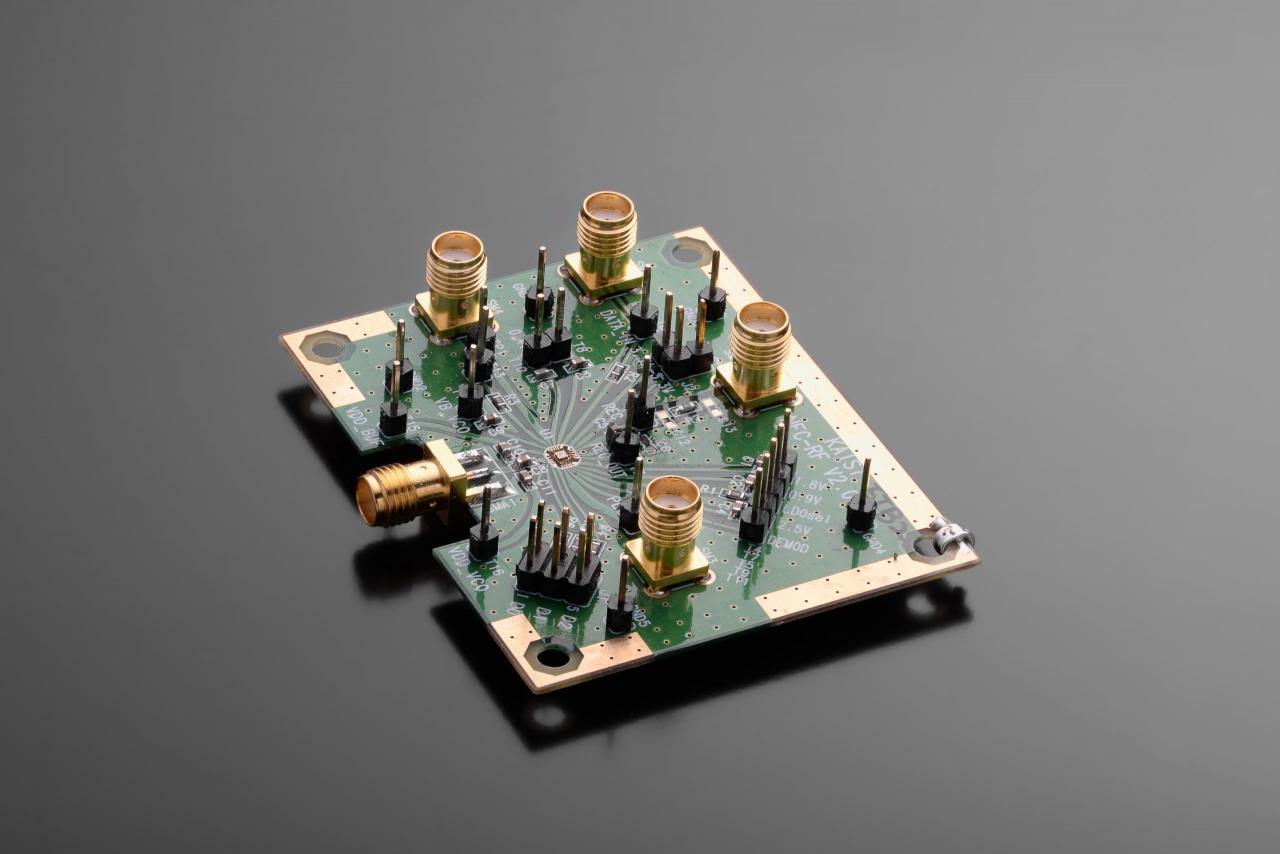

Wireless transceiver circuit designed by BKIC Laboratory, Hanoi University of Science and Technology.

In addition, chips using older technology such as sensors, LED control with large market demand, or chips for security, encryption to ensure information security in the field of national security and defense may also need investment attention. "Regardless of which type of semiconductor chip to focus on, market demand must be a factor that needs careful attention" - Associate Professor, Dr. Nguyen Duc Minh noted.

To improve Vietnam's position on the world chip map, Chairman of FPT Information System Company Tran Dang Ho emphasized that the private sector needs to be brave to participate in this field: "What we need is not 1-2 companies, 1-2 people but an entire industry with hundreds of companies. We must turn Vietnam into a "market" with many choices. If investors do not like this company, they can immediately find another company" - Mr. Hoa said and believed that it is necessary to take advantage of the inherent competitiveness to increase Vietnam's attractiveness on the world chip map.

Regarding human resources for the semiconductor industry, Mr. Tran Dang Hoa assessed that Vietnam has a great advantage in terms of human resources because Vietnamese people are very good at math and natural sciences. We have built a software industry with 1 million programmers. Vietnam's software industry is not inferior to the world's average.

According to FPT representative, the transition from software to hardware does not have too many obstacles in certain stages. On average, FPT takes 6 months to 1 year to train and convert a software engineer to hardware, to chip making. Of course, the chip design process will have many stages, some stages still require 5, 10 to 20 years to train human resources. But there are also particularly simple stages, only needing 6 months to 1 year of training for engineers to be able to do.

Mr. Tran Dang Hoa, Chairman of FPT Information System Company

“Human resources for this industry are not picky but need to be meticulous and detailed. Many Korean and Japanese engineers do not like chip design because this industry is not very dynamic. In fact, many Vietnamese people have become famous in the field of chip design worldwide,” said Mr. Hoa. In addition, low labor costs are also a competitive advantage of Vietnam.

The advantage of Vietnamese human resources in the semiconductor industry was also emphasized by Minister of Information and Communications Nguyen Manh Hung when he said that the passion for STEM subjects is like a part of the DNA of Vietnamese people. The qualities of Vietnamese people are very suitable for the development of the semiconductor industry.

According to Associate Professor, Dr. Nguyen Duc Minh (Hanoi University of Science and Technology), Vietnam's human resources are still relatively young, with the number of students studying STEM majors reaching about 30% (source: World Economic Forum) out of a total of about 600,000 students entering universities nationwide each year.

Vietnamese human resources are considered quite good with mathematical, physical, and chemical abilities as the foundation to participate in the Electronics-Semiconductor field, but are still weak in foreign language skills and professional working attitude which are the most important factors in an industry that requires high precision.

For more information, Associate Professor, Dr. Nguyen Duc Minh said that Hanoi University of Science and Technology has a tradition of research and training in the field of semiconductors, design, manufacturing of microchips and electronic devices. Since the 1970s, the Department of Solid State Physics under the Faculty of Mathematics and Physics of the university has begun training students in Solid State Physics, with an in-depth orientation in the field of semiconductors. In 1977, with the help of the Netherlands, Hanoi University of Science and Technology built the first cleanroom Microelectronics Laboratory in Vietnam managed and operated by the Department of Solid State Physics. At this Microelectronics Laboratory, in 1977, a group of experts led by Professor Vu Dinh Cu successfully manufactured the first field-effect transistor based on the MOS (Metal - Oxide - Semiconductor) structure using polycrystalline silicon as the gate electrode (the latest technology at that time) in Vietnam.

Since 2010, the Electronics - Telecommunications Department of Hanoi University of Science and Technology has started training microchip design engineers with a foundation of knowledge in electronics and computer engineering. From 2023, Microchip Design will be made a major of the Electronics - Telecommunications Department.

Also last year, Hanoi University of Science and Technology officially opened the Microelectronics and Nanotechnology Engineering Program under the School of Materials to train microchip manufacturing engineers. The total enrollment budget for the microchip training programs of Hanoi University of Science and Technology will be about 700 students per year.

Speaking at the 6th Session of the 15th National Assembly in November 2023, Minister of Education and Training Nguyen Kim Son informed that Vietnam currently has 35 higher education institutions directly training in semiconductors or related fields such as information technology, electronics and telecommunications. Students studying related fields can supplement and transfer to immediately have human resources to take on jobs in this field.

The Minister said that it is expected that in 2024, over 1,000 workers will be recruited and trained in the field of direct semiconductor design. Related fields will recruit about 7,000 and this number will gradually increase from 20 to 30% annually.

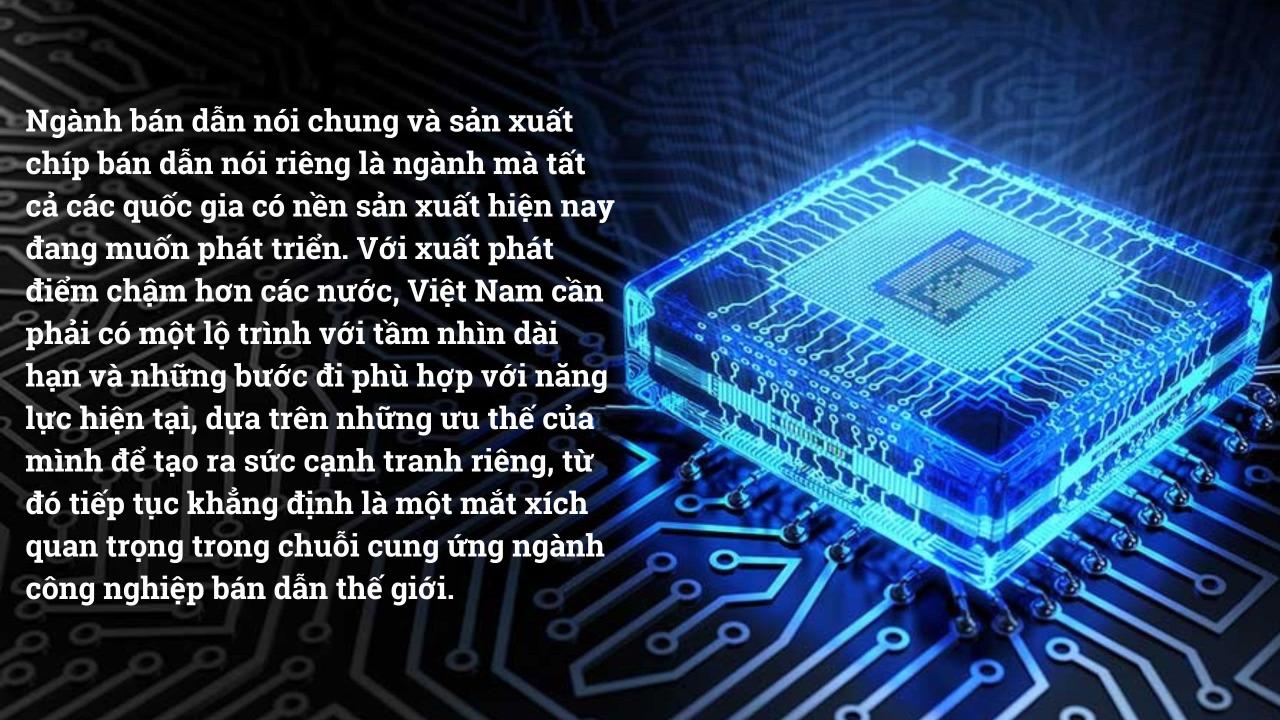

According to experts, Vietnam is facing a huge and final opportunity to catch the wave of supply chain shift and participate in the semiconductor industry chain. However, to grasp and successfully take advantage of this opportunity, Vietnam needs to act now and have a long-term strategy for the next 20 years.

Economist Vo Tri Thanh, former Deputy Director of the Central Institute for Economic Management (CIEM), said that in the semiconductor manufacturing supply chain, Vietnam is currently only participating in three stages, partly in design, packaging and testing. However, in the future, we can expect Vietnam to upgrade and become an important link in the complete semiconductor industrial ecosystem including: design, production, packaging and testing, equipment manufacturing and diversified businesses with many components, capable of mastering some core technologies.

Economist Vo Tri Thanh, former Deputy Director of the Central Institute for Economic Management (CIEM)

Mr. Thanh assessed that Vietnam is entering a turning point that requires development. This is a period when we need to quickly catch up with new trends, green, digital, supply chain shifts... Because if we cannot take advantage of this leap, it will be very difficult for Vietnam to develop.

According to him, to do this, Vietnam needs to form a network of “incubators” for semiconductor businesses at the National Innovation Center (NIC), high-tech parks in Hanoi, Ho Chi Minh City and Da Nang, with enough high-quality human resources, technical workers, and practical engineers. In particular, it is necessary to link the semiconductor industry with electronics technology, one of Vietnam’s strengths.

Chairman of FPT Information System Company Tran Dang Hoa also said that Vietnam needs to build a semiconductor industry ecosystem with complete components, including: manufacturing plants, design companies, schools, research institutes, etc. Citing the fact that Vietnam does not have a domestic manufacturing plant, Mr. Hoa suggested that it is necessary to quickly call on foreign businesses and partners to open factories in Vietnam.

From another perspective, Associate Professor, Dr. Nguyen Duc Minh emphasized that the semiconductor industry is an extremely strict industry in terms of electricity and water requirements, and currently, Vietnam has not met these requirements.

Experts from Hanoi University of Science and Technology informed that a semiconductor wafer manufacturing plant consumes about 40 million liters of water per day (40,000m3) - equivalent to the water consumption of 120,000 people. Of that, up to 76% is treated water that meets ultra-clean standards. To have ultra-clean water for semiconductor technology, clean water needs to go through many processing steps such as distillation, ion separation, removal of dissolved substances in water... so the actual amount of water consumed will be many times more than 40,000m3.

In addition, in 2021, the entire semiconductor manufacturing industry consumed up to 149 billion kWh of electricity - equivalent to the electricity consumption of 25 million people per year. A factory will need to consume about 4 billion kWh of electricity and 30 million m3 of ultra-clean water per year, while the electricity output of Hoa Binh Hydropower Plant is 9-10 billion kWh per year.

Along with ultra-pure water, the semiconductor industry requires ultra-clean environments for production - clean rooms. Cleanliness in a clean room is determined by the number of particles smaller than a specific size in a unit volume. Most integrated circuit manufacturing in the semiconductor industry is done in a class 100 clean room - that is, containing a maximum of 100 dust particles with a diameter greater than or equal to 0.5µm (1µm = 0.0000001m) in a cubic foot (1 ft3 = 28.3 liters) of air. The higher the technology, the smaller the critical size of the dust particles. To operate or just maintain these clean rooms already consumes a huge amount of electricity.

Along with ultra-pure water, the semiconductor industry requires ultra-clean environments for production - clean rooms. Cleanliness in a clean room is determined by the number of particles smaller than a specific size in a unit volume. Most integrated circuit manufacturing in the semiconductor industry is done in a class 100 clean room - that is, containing a maximum of 100 dust particles with a diameter greater than or equal to 0.5µm (1µm = 0.0000001m) in a cubic foot (1 ft3 = 28.3 liters) of air. The higher the technology, the smaller the critical size of the dust particles. To operate or just maintain these clean rooms already consumes a huge amount of electricity.

Semiconductor manufacturing test clean room of Hanoi University of Science and Technology.

It can be seen that the immediate construction of a semiconductor factory will increase pressure on Vietnam's clean water and electricity supply. According to Associate Professor, Dr. Nguyen Duc Minh, Vietnam needs a long-term strategy with a master plan to increase the supply of clean water and electricity if it wants to develop the semiconductor manufacturing industry.

In addition, the semiconductor industry is known for its high emissions, up to 1 million tons of CO2 per year per factory. Meanwhile, Vietnam is expected to emit about 65 million tons of CO2 by 2025. Thus, a semiconductor factory will contribute about 1.6% of Vietnam's emissions. In particular, importing old technologies will further increase the factory's emissions. "Therefore, promoting clean, green energy sources and only allowing clean, green technologies is a measure that Vietnam needs to pursue," Associate Professor, Dr. Nguyen Duc Minh stated.

In terms of human resources, experts share the same opinion about the shortage of human resources for the semiconductor industry on a global scale, and believe that Vietnam must start preparing this high-quality human resource right now to meet the recruitment needs of international semiconductor enterprises when investing in Vietnam in the near future.

Recently, a series of domestic universities and training institutions have announced plans to enroll students in the fields of electronics, microchips, and semiconductors, aiming at the challenging goal of training and developing about 50,000 human resources for the Vietnamese semiconductor industry by 2030. Most recently, five higher education institutions including Hanoi National University, Ho Chi Minh City National University, Danang University, Hanoi University of Science and Technology, and the Academy of Posts and Telecommunications Technology signed a memorandum of understanding to promote potential and strengths, and agree on an action plan with Vietnamese higher education institutions to be ready to ensure and improve the quality and effectiveness of training high-quality human resources to serve the development needs of the semiconductor industry.

Student at the microchip design laboratory, Hanoi University of Science and Technology

According to Associate Professor, Dr. Nguyen Duc Minh, ensuring adequate human resources for the semiconductor industry is necessary, but the output quality of Vietnamese semiconductor engineers is also an issue that needs special attention, how to ensure meeting the recruitment requirements of businesses, because the semiconductor industry is a rather "conservative" industry that requires experienced human resources, not simply specialized training.

In addition, it will take at least 4 years to train human resources in the semiconductor industry. Experts believe that converting available engineering resources from fields such as computer engineering, electronics, electricity and automation, engineering physics, etc. is a feasible solution in case a semiconductor workforce is required to participate in the market in the near future.

In terms of state management, the Ministry of Information and Communications emphasized that in the context of countries in the region such as China, India, Japan, Korea, Malaysia, Singapore, etc. offering special incentives for the semiconductor industry, Vietnam needs solutions and policies to exploit domestic strengths and take advantage of foreign resources to build a suitable development strategy.

Specifically, it is necessary to perfect the system of mechanisms and policies to create breakthroughs in the development of the semiconductor industry through the development of specific and outstanding policies such as tax incentives, financial support, etc. to attract investment, experts, support businesses and training facilities to develop the semiconductor industry.

Publication date: February 11, 2024 Production organization: Thao Le Performed by: Van Toan - Thi Uyen Video: Trung Hieu Image: FPT, Hanoi University of Science and Technology

Nhandan.vn Source link

Comment (0)